Optical sheet and application thereof

A technology of optical sheets and three-dimensional optics, applied in optics, optical components, nonlinear optics, etc., can solve problems such as energy loss, increase in material and production costs, and achieve the effect of reducing material costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

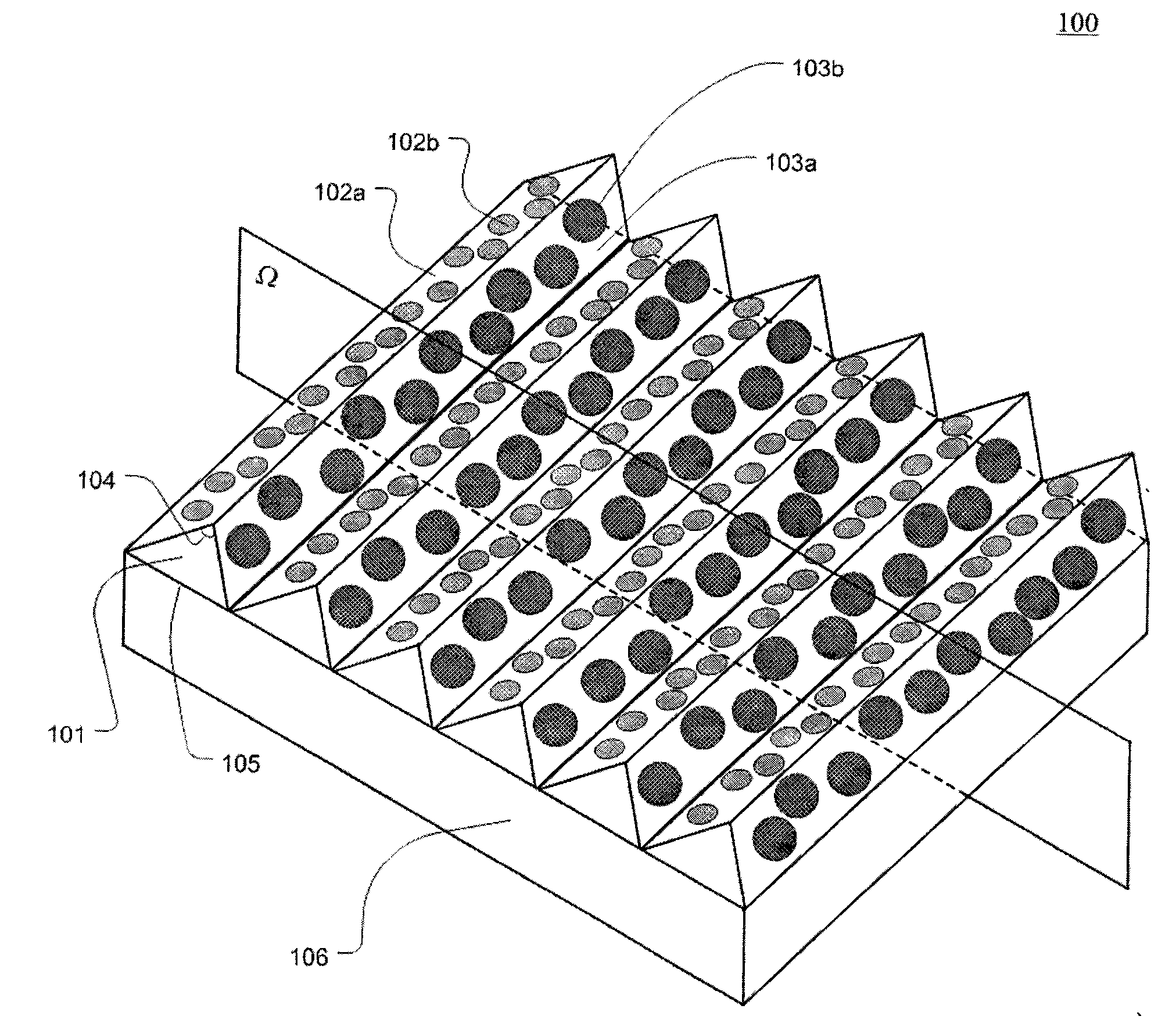

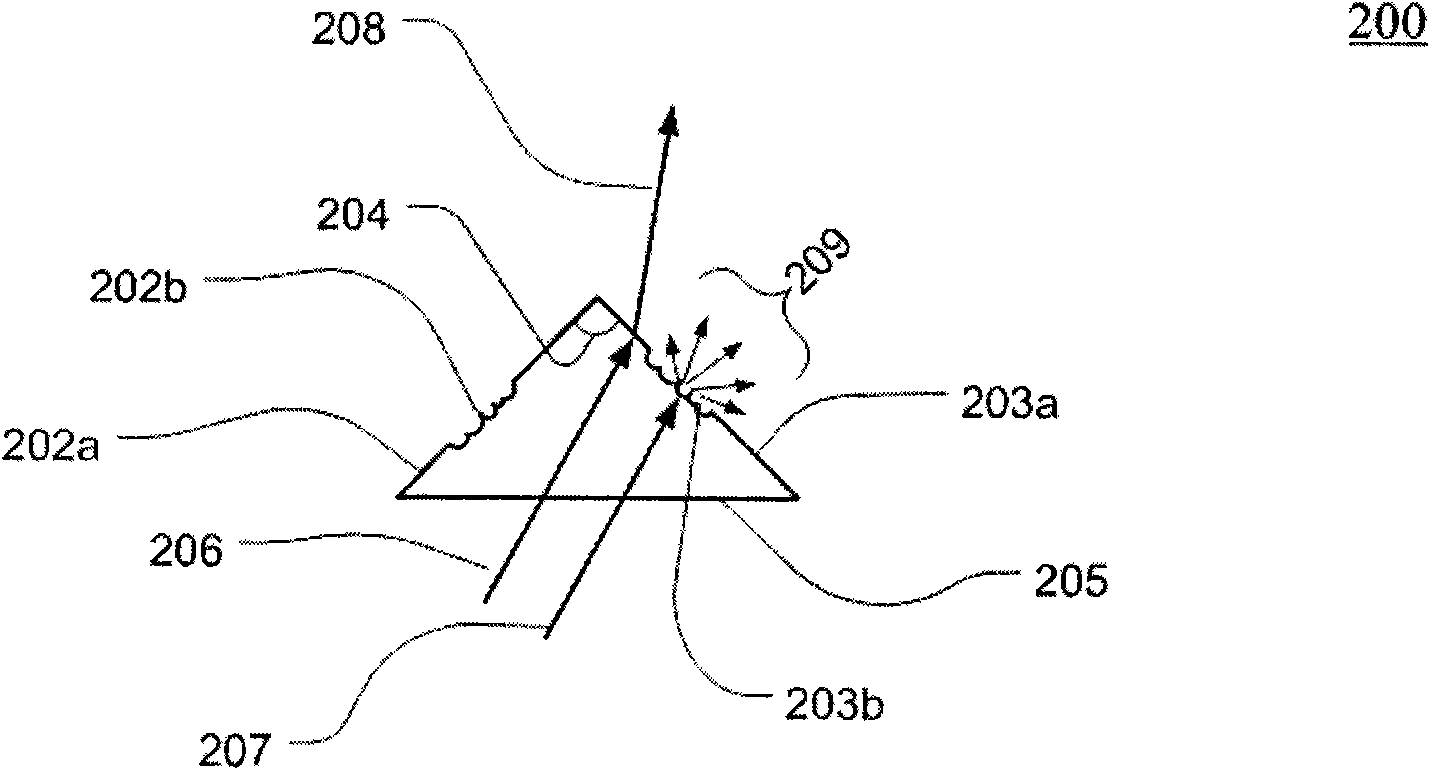

[0026] An optical sheet, one side contains multiple three-dimensional optical structures. The three-dimensional optical structure includes a bottom surface and multiple sides. The bottom surface of the three-dimensional optical structure is the light incident surface, and multiple sides are the light output surface. The side surfaces of the three-dimensional optical structure are composed of two types of surface areas with different characteristics. The first type of surface area is a smooth surface area, which plays the role of concentrating light; The quasi-surface region is a rough surface region, which plays a role in diffusion; the rough surface region can be composed of a plurality of concave microstructures, or a plurality of raised microstructures, or a combination of a plurality of concave and a plurality of raised microstructures . The sides of the three-dimensional optical structure contain a plurality of smooth surface regions and a plurality of rough surface regi...

Embodiment 2

[0035] Figure 4 It is the second example of the optical sheet of the present invention. The invention provides an optical sheet. One side of the optical sheet contains multiple three-dimensional optical structures. The three-dimensional optical structure includes a bottom surface and multiple sides. The sides of the three-dimensional optical structure contain alternately arranged smooth and rough surface regions. The other side of the optical sheet contains a coating layer containing particles that protrude from the surface of the coating layer to reduce the contact area between the optical sheet of the present invention and adjacent surfaces, prevent bonding with adjacent surfaces and prevent impact Interference patterns showing image quality.

[0036] The optical sheet 400 contains a plurality of three-dimensional optical structures 401 . The side 402 (not shown) of the three-dimensional optical structure 401 includes a smooth surface region 402a and a rough surface reg...

Embodiment 3

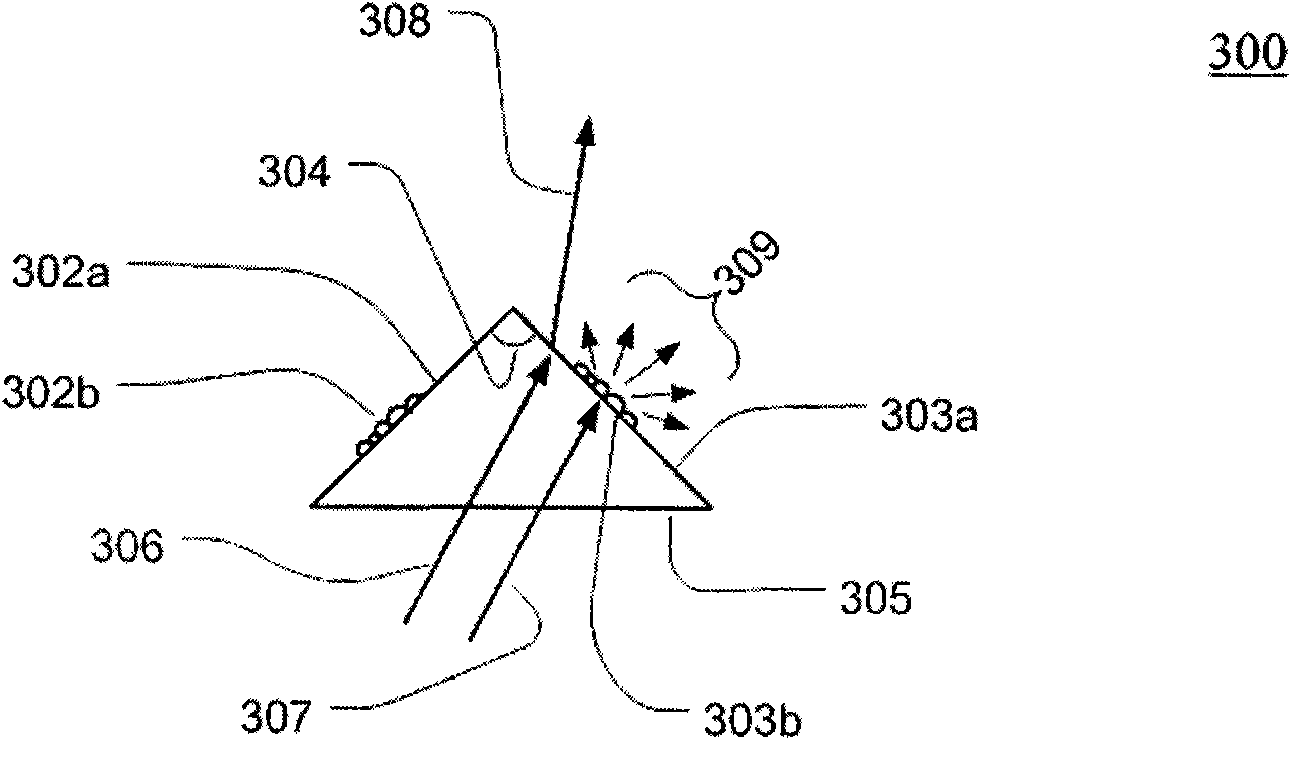

[0038] Figure 5 It is the third example of the optical sheet of the present invention. The optical sheet 500 contains a plurality of three-dimensional optical structures 501 . The side 502 (not shown) of the three-dimensional optical structure 501 includes a smooth surface region 502a and a rough surface region 502b. The side 503 (not labeled) of the three-dimensional optical structure includes a smooth surface region 503a and a rough surface region 503b. The side 502 of the three-dimensional optical structure intersects with the side 503 to form an included angle, as shown by 504 in the figure. The three-dimensional optical structure 501 is curved along the length of the structure. The intersection line formed by the side surface 502 and the side surface 503 is a curved curve, as shown by 505 in the figure. The example optical sheet also includes a substrate 506 . The substrate 506 is generally a transparent optical material, such as PET, PC, or PMMA. In the example op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com