Aircraft engine assembly comprising an annular load-transfer structure surrounding the central casing of a turbojet engine

An annular structure, turbojet technology, applied in the direction of machines/engines, aircraft parts, jet propulsion devices, etc., can solve the problems of annular structure and/or center shell deformation, unoptimized connecting rod arrangement, etc., to achieve optimal mechanical connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

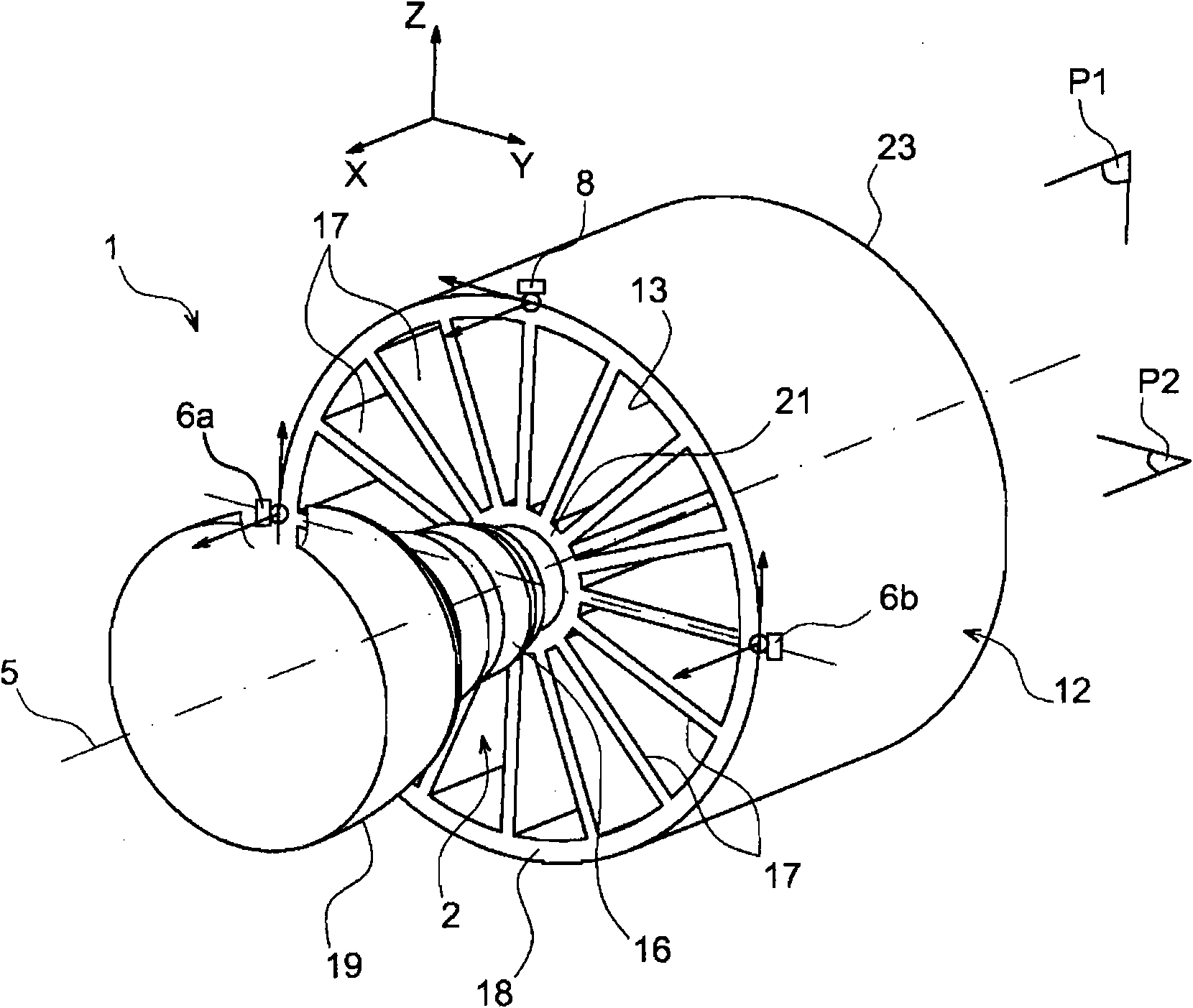

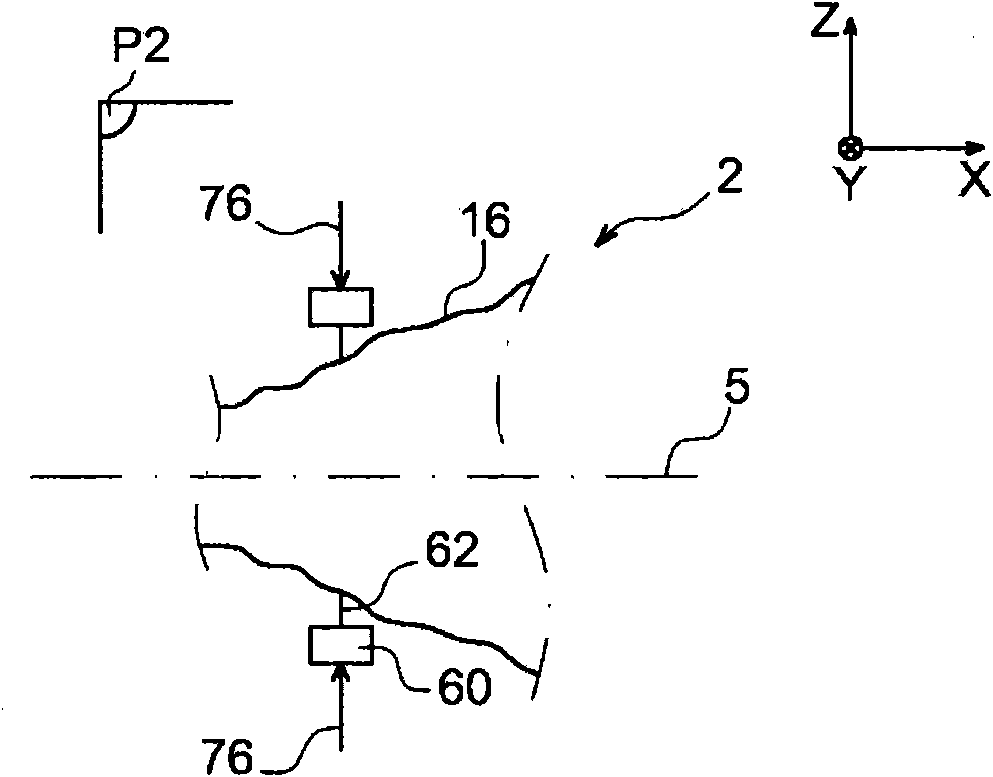

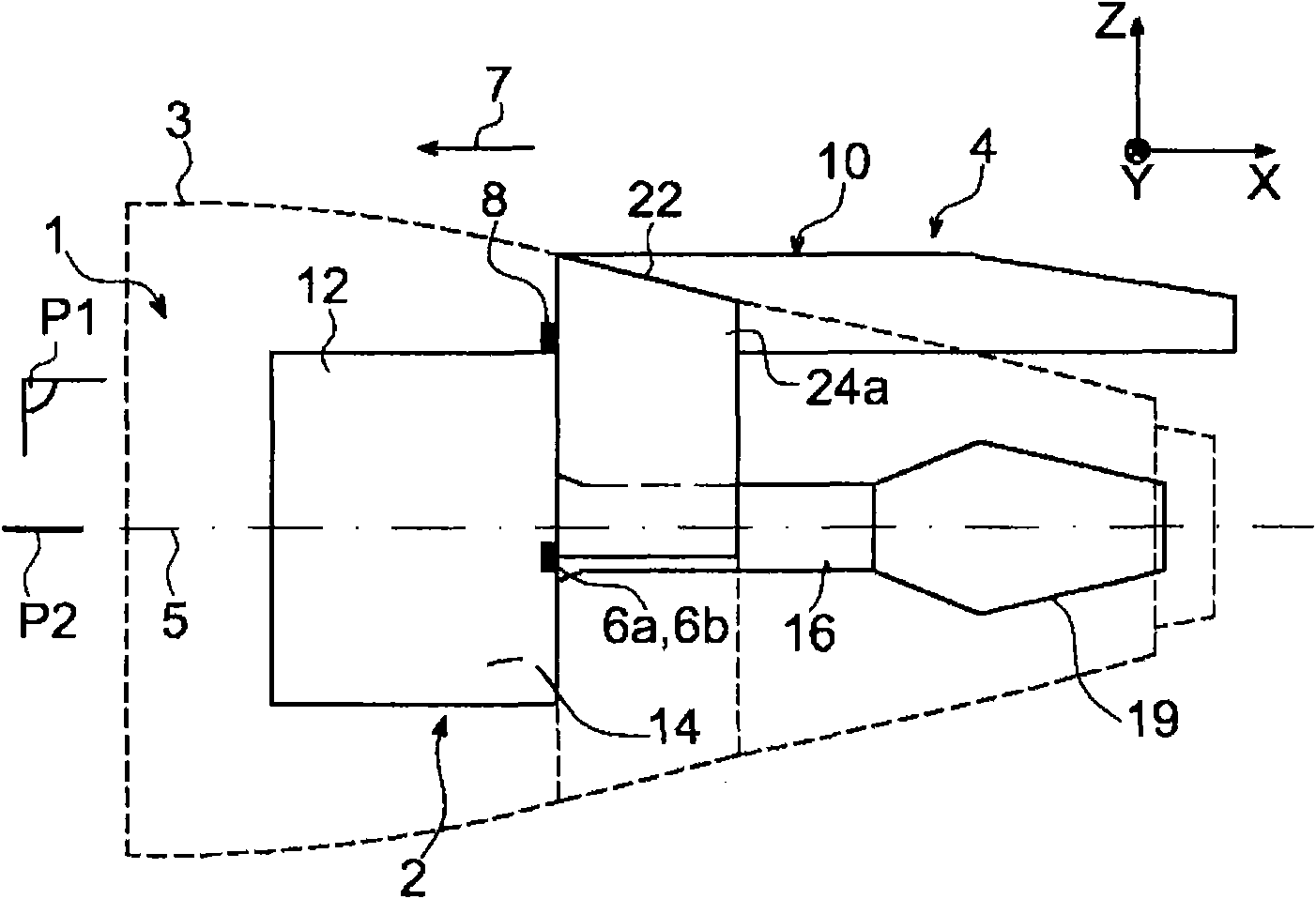

[0054] refer to image 3 , there can be seen an engine assembly 1 for an aircraft according to a preferred embodiment of the present invention, which assembly 1 is fixed under an aircraft wing (not shown).

[0055] Overall, the engine assembly 1 is also referred to as an integrated propulsion system, which consists of a turbojet engine 2, a nacelle 3 (shown in dashed lines for clarity), and suspension means for suspending the turbojet engine on a suspension frame 4, which The device preferably consists of a plurality of engine fasteners 6a, 6b, 8 which are fixedly connected to the rigid structure 10 of the hanger (here image 3 , the fastener 6b is covered by the fastener 6a). As an illustration, it should be noted that the assembly 1 includes a further set of fasteners (not shown) for securing the suspension of the assembly 1 under the wing of the aircraft.

[0056] Throughout the following description, by convention, X is referred to as the longitudinal direction of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com