Moving mechanism of automatic steel bar bender

A technology of moving mechanism and bending machine, which is applied in the field of moving mechanism, can solve the problems such as the inability to automatically adjust the gap between the gear and the rack, the bumpy running of the automatic steel bar bending machine, and the difficulty in ensuring the straightness of the rack, etc., to achieve light weight, low cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

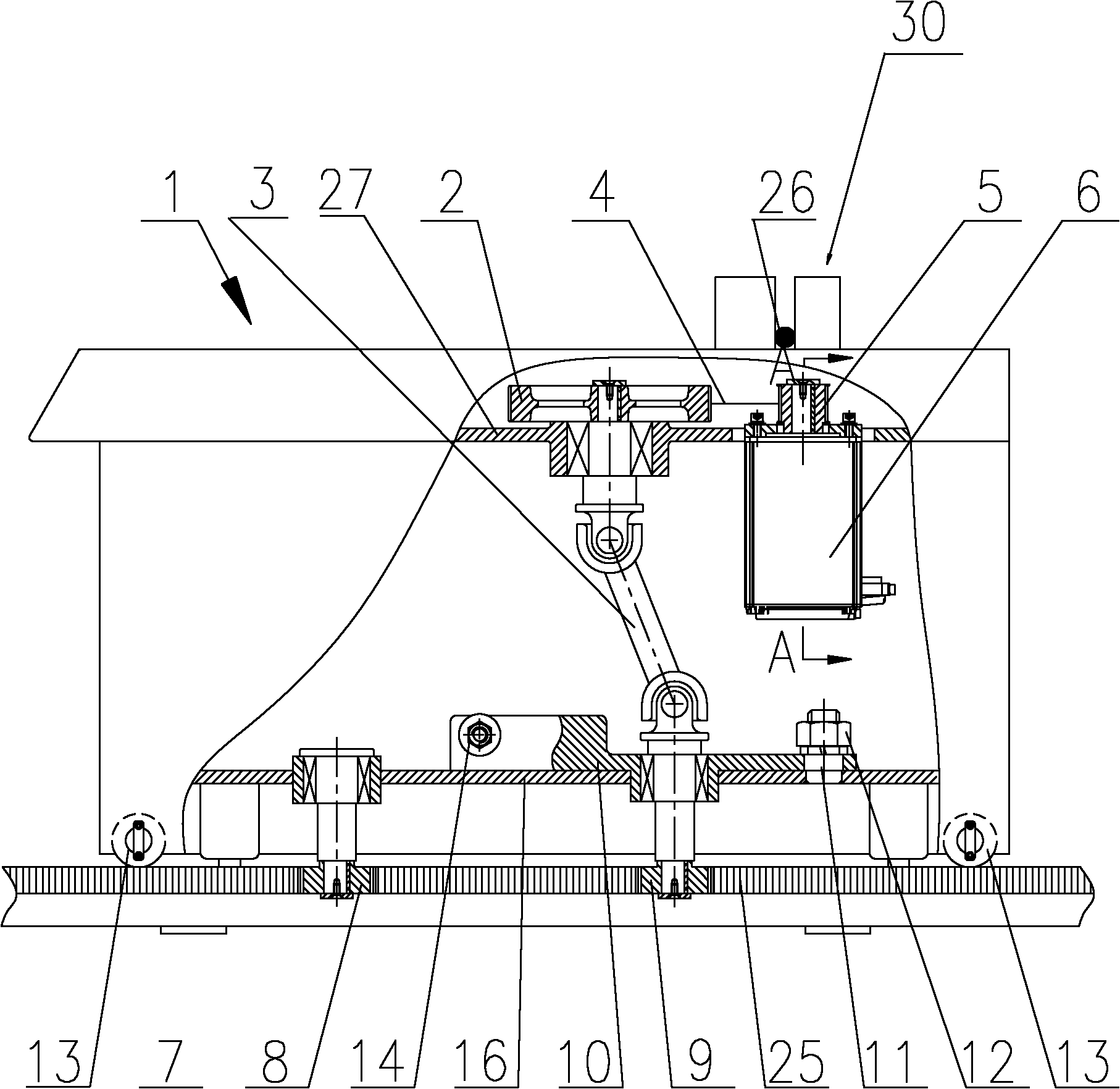

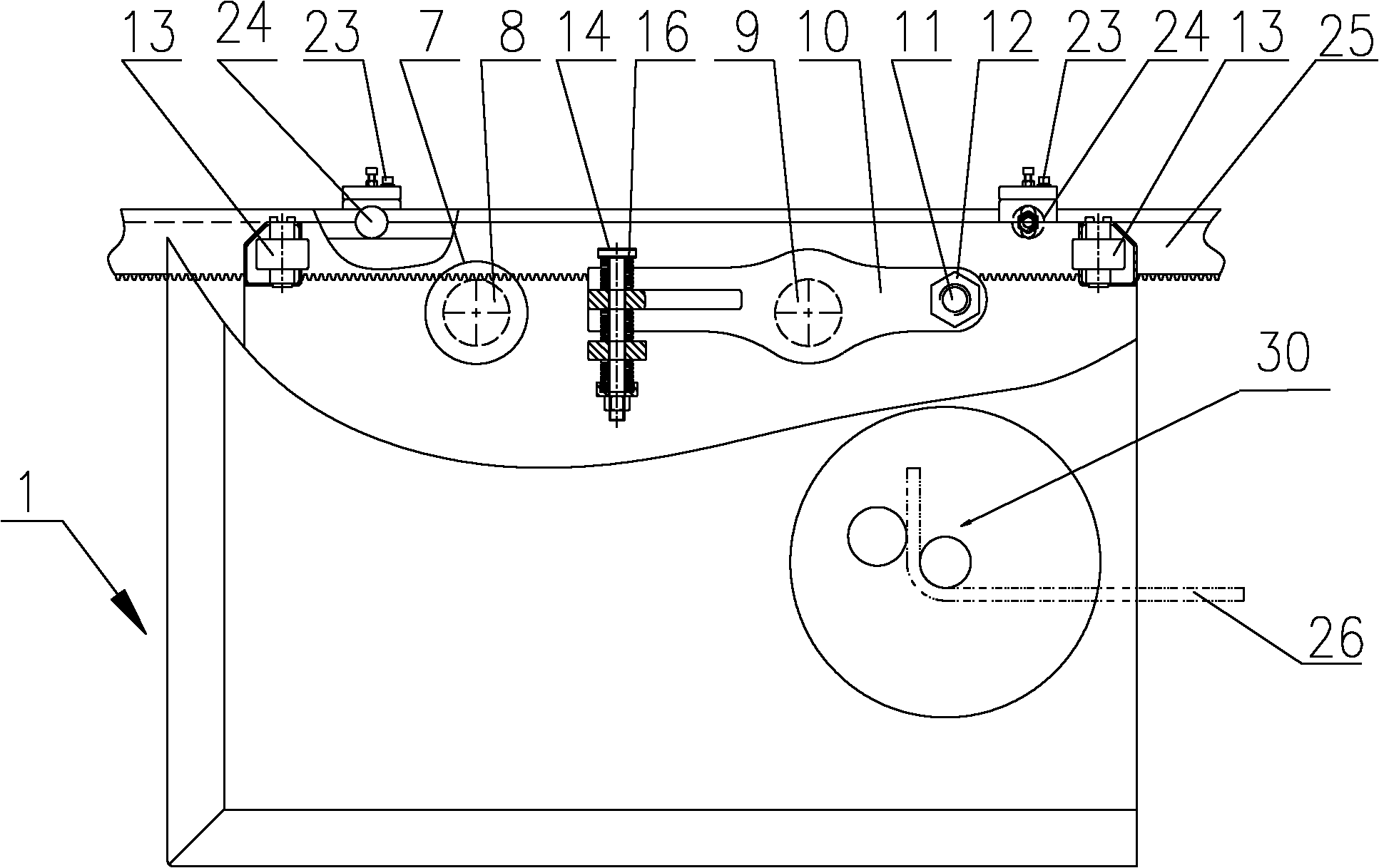

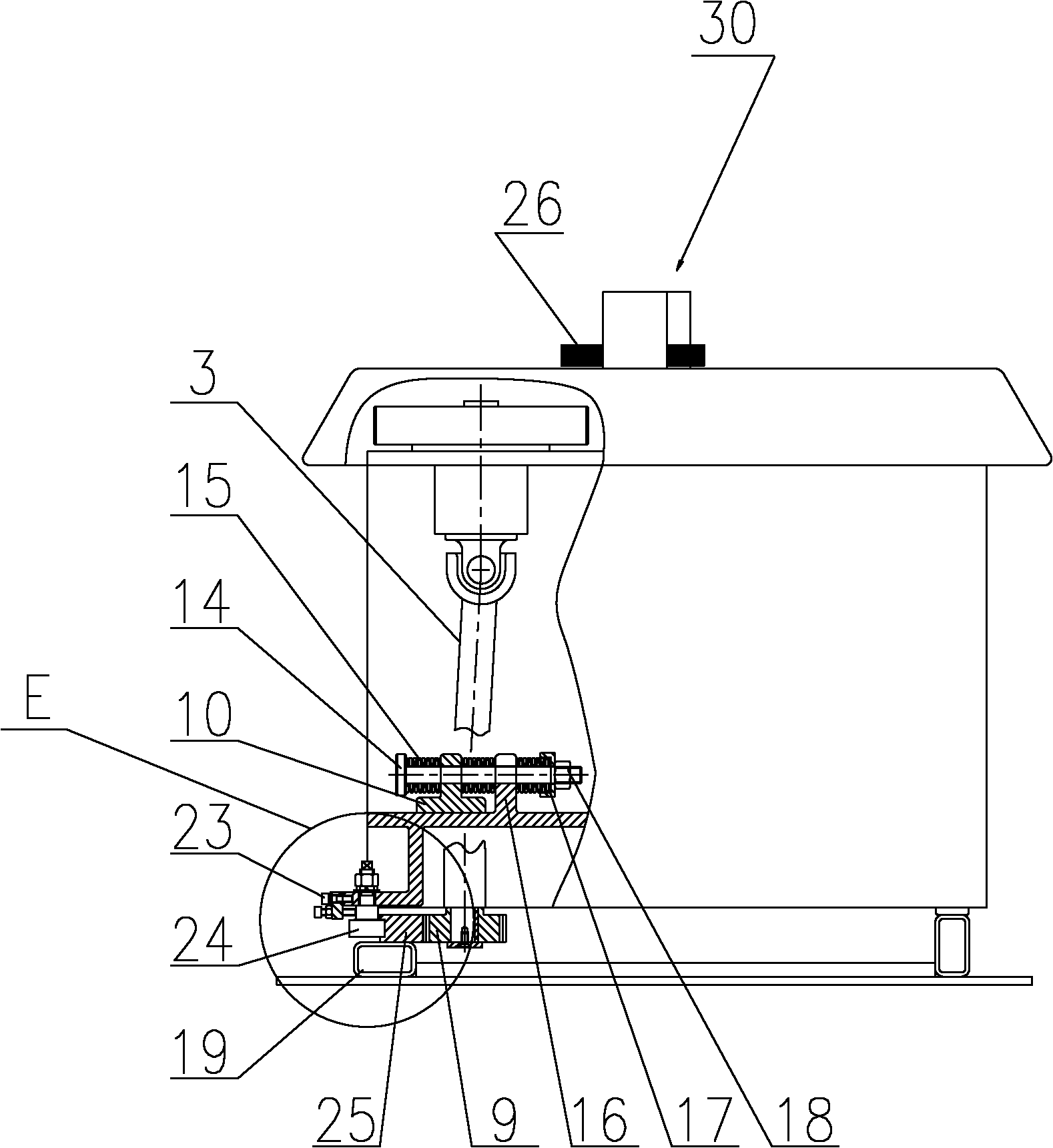

[0016] figure 1 It is a front view with a partial section of the present invention; figure 2 yes figure 1 Top view with partial section in ; image 3 yes figure 1 Left side view with breakout in ; Figure 4 yes figure 1 Middle A-A sectional view; Figure 5 yes image 3 Enlarged view of middle A and E.

[0017] As shown in the figure, the present invention provides a moving mechanism of a steel bar automatic bending machine, the moving mechanism includes: a track rack 25; a bending machine box 1 that moves along the track rack 25; The driving gear 9 meshed with the rack 25, the driving mechanism for driving the driving gear 9 to rotate includes: the driving gear 9 is connected to one end of the universal coupling 3, and the other end of the universal coupling 3 is connected to the output of the conveyor belt transmission mechanism. The input end of the conveyor belt transmission mechanism is connected to the power drive unit 6.

[0018] The shaft at one end of the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com