Oil-free pump for high-pressure cleaning machine

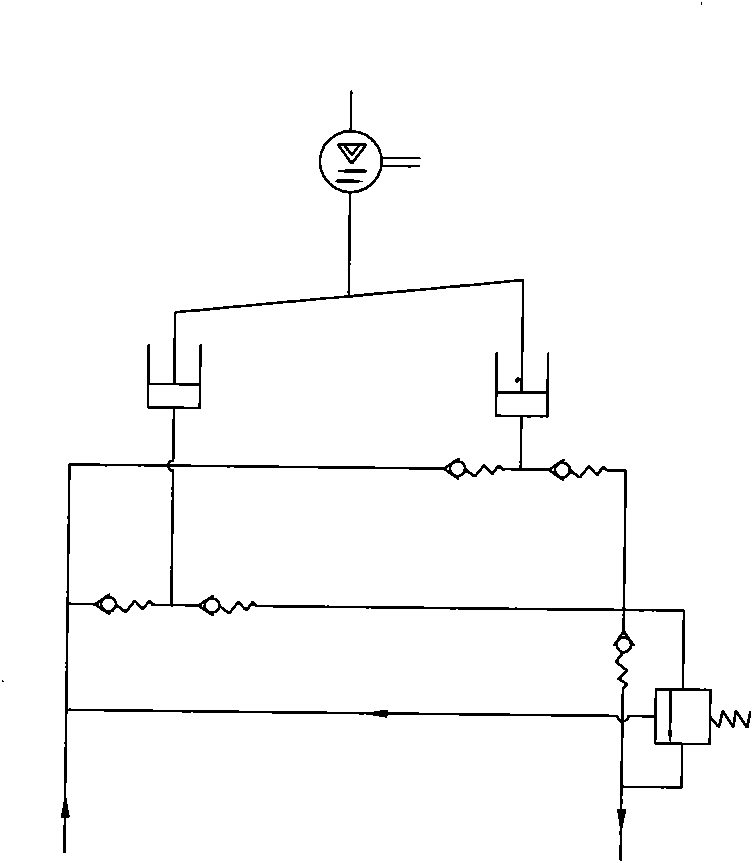

A high-pressure cleaning machine, oil-free pump technology, applied in the direction of pumps, piston pumps, mechanical equipment, etc., can solve problems such as easy generation of oil pressure, oil and gas, water running into the oil tank, oil and water mixing, etc., to reduce friction loss, improve Efficiency, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

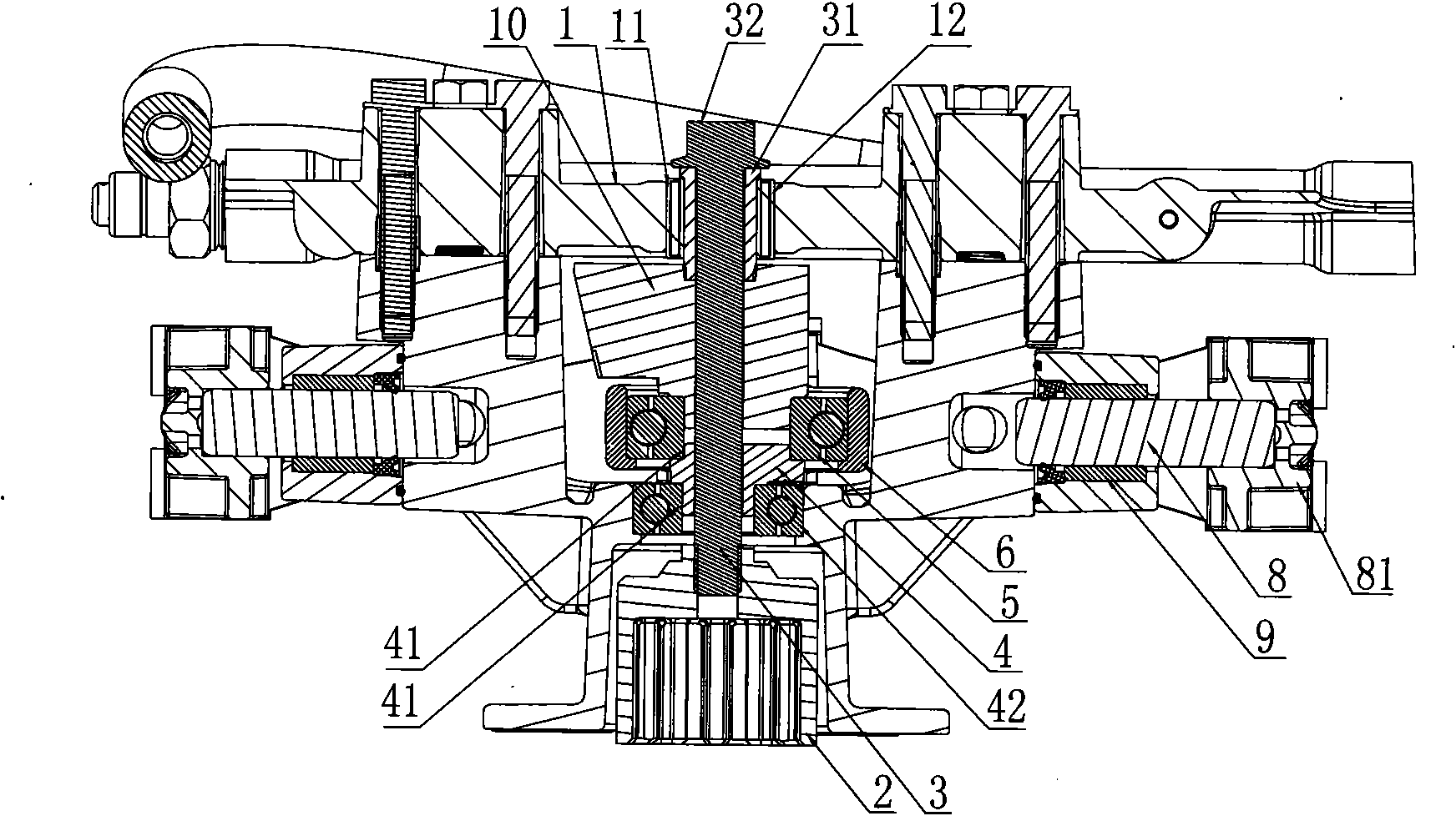

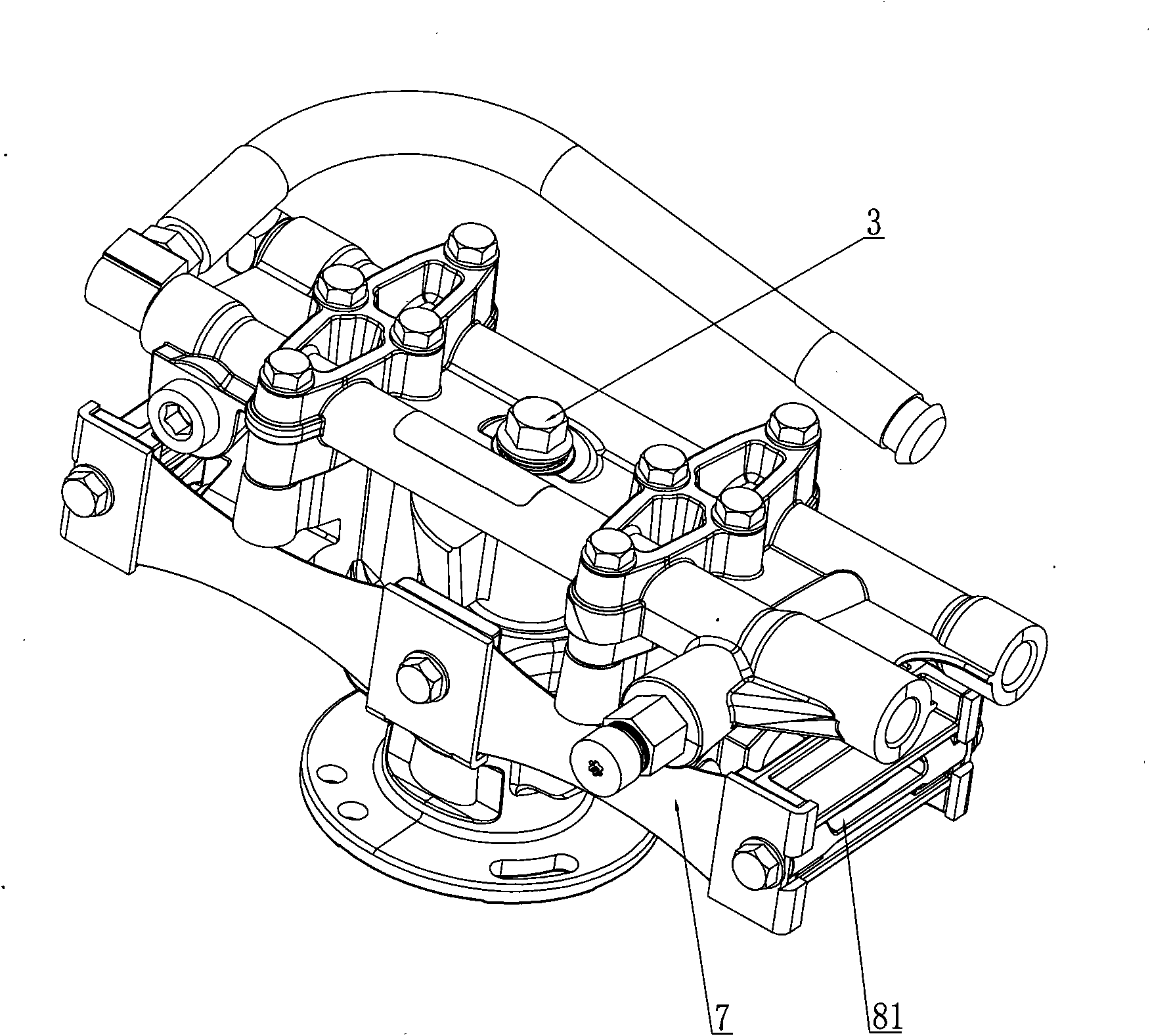

[0021] Embodiment: An oil-free pump for a high-pressure cleaning machine, including a pump body 1, a transmission shaft 2 and a rotating shaft 3. Based on the direction of use, the rotating shaft 3 can be rotatably inserted in the pump body 1, and the transmission shaft 2 and the rotating shaft 3 is fixedly connected, and an eccentric wheel 4, a rotating ring bearing 5, a rotating ring 6, an elastic steel plate 7, a plunger 8 and a plunger bearing 9 are also provided, the eccentric wheel 4 is fixed on the outer side of the rotating shaft 3, and the outer side of the eccentric wheel 4 is sleeved There is a rotating ring bearing 5, and the rotating ring 6 is sleeved on the outer side of the rotating ring bearing 5, the outer wall of the rotating ring 6 is fixedly connected with the middle section of the side wall of the elastic steel plate 7, and the two end walls of the elastic steel plate 7 are respectively fixedly connected with a plunger 8, and the column The plug 8 can be sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com