Internal spherical gear and external spherical gear

A technology of inner spherical surface and outer spherical surface, applied in the direction of gear transmission, belt/chain/gear, components with teeth, etc., can solve the problems of large starting and running load, insufficient strength of teeth, inconvenient heat treatment and quenching, etc. The effect of increasing torque and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

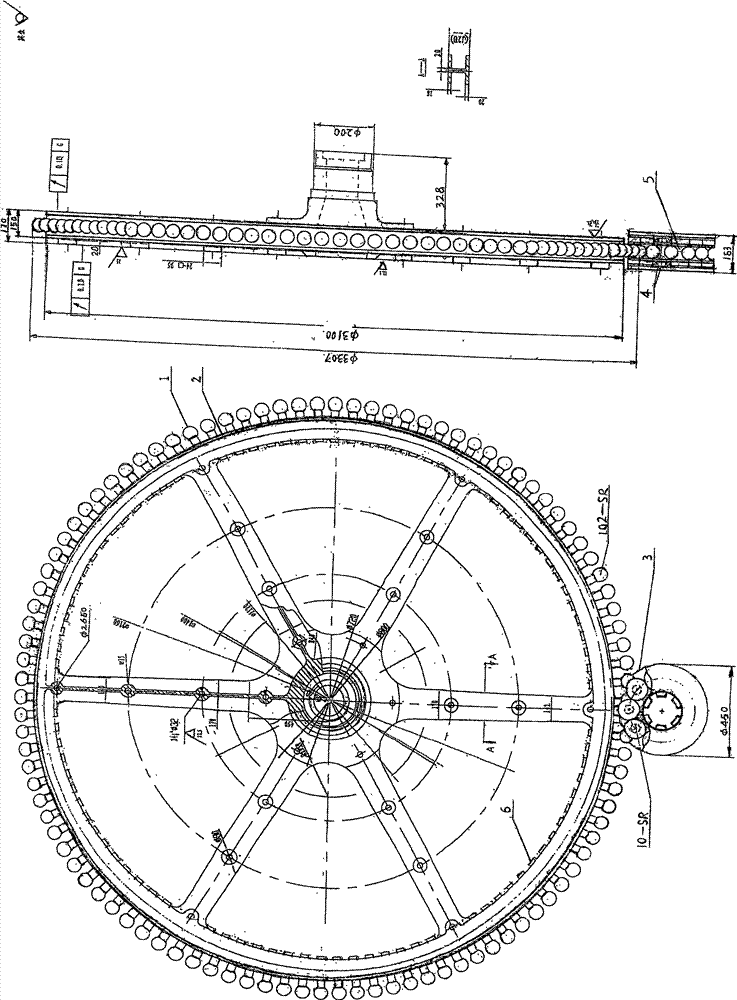

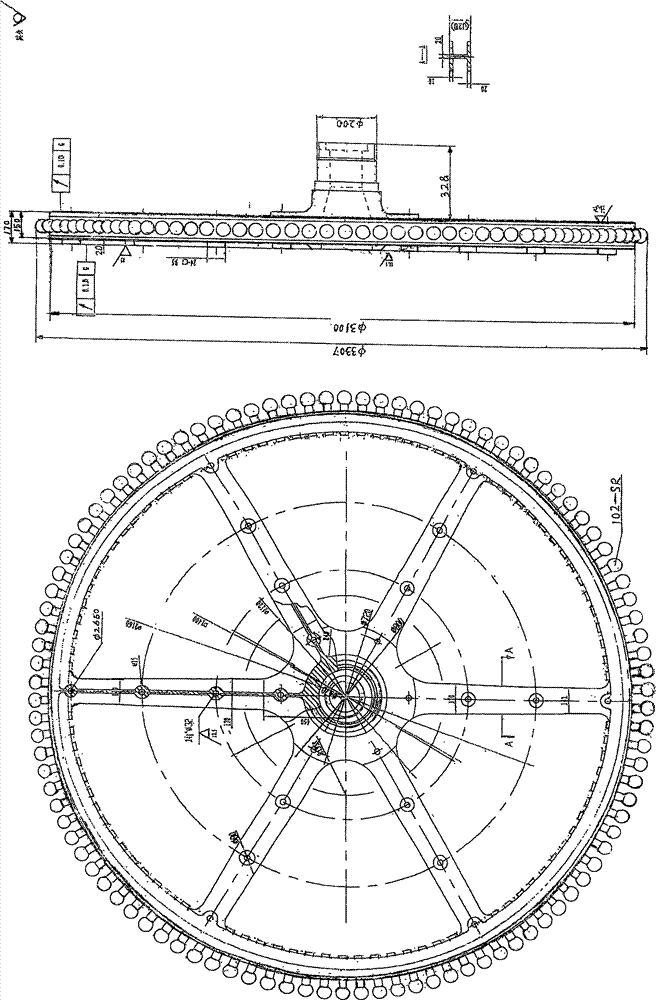

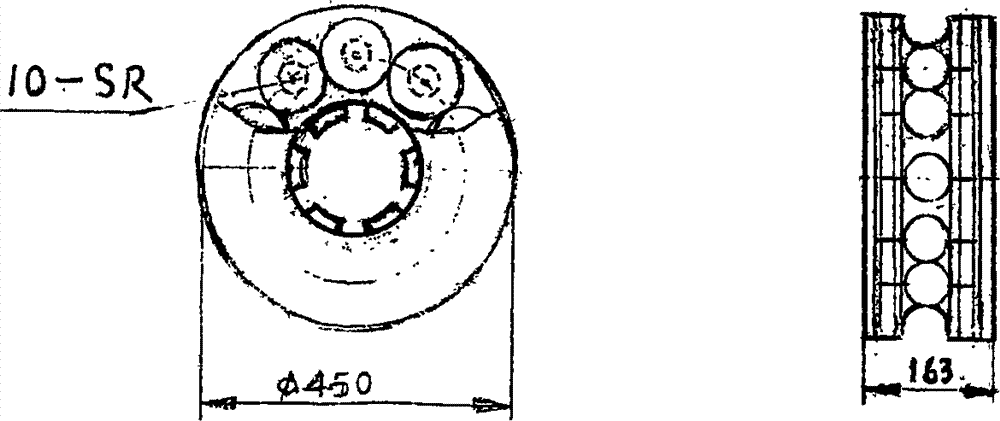

[0022] this invention figure 1 , Figure 4 , Figure 7 The optimization of the inner spherical gear and the outer spherical gear lies in: using the principle of spherical lines, adopting spherical tooth shape and high-frequency quenching, it can form a heavy-duty rotary transmission rigidity that cannot be easily obtained by traditional spur gear transmission methods. The spherical gear 5 twists the outer spherical gear 1 to rotate, and the outer spherical gear 1 drives the inner spherical gear 5 (under the action of the bearing) to slide in the same direction, which solves the hard friction and easy wear between the inner spherical gear 5 and the outer spherical gear 1 , the production and use time is long, the inner spherical gear 5 and the outer spherical gear 1 can be disassembled and replaced, and the new inner spherical gear 5 and outer spherical gear 1 can be replaced. The large and small gear ring seats 2 and 3 should not be replaced. The waste of energy greatly save...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com