A multi-purpose fiber opening and mixing bin system

A multi-purpose, mixing bin technology, used in fiber mixing, fiber processing, opening and cleaning machines, etc., can solve the problems of no fast connection interface, frequent connection, easy to pollute the cashmere, etc., to reduce labor, avoid Pollution, natural slippage beneficial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

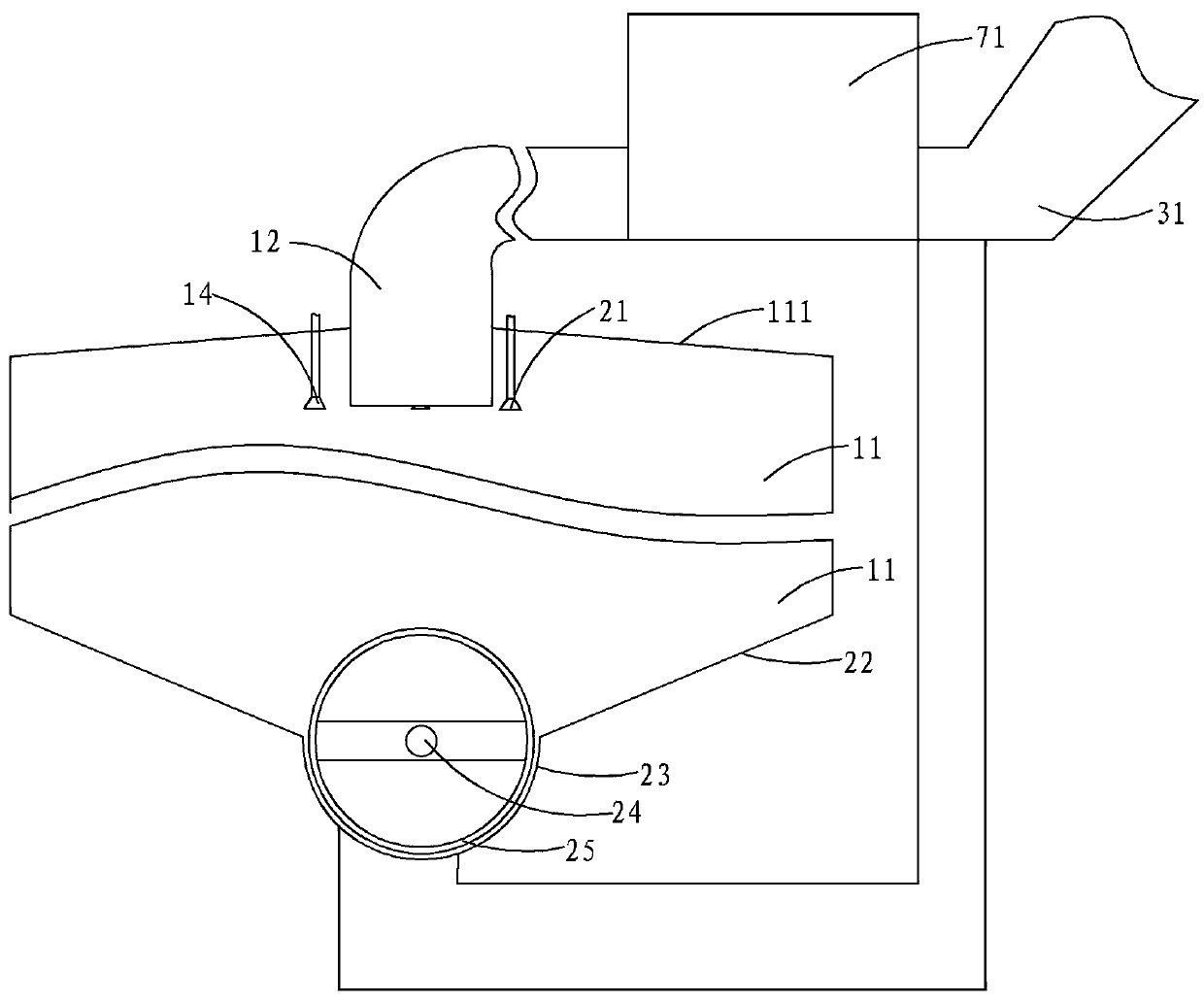

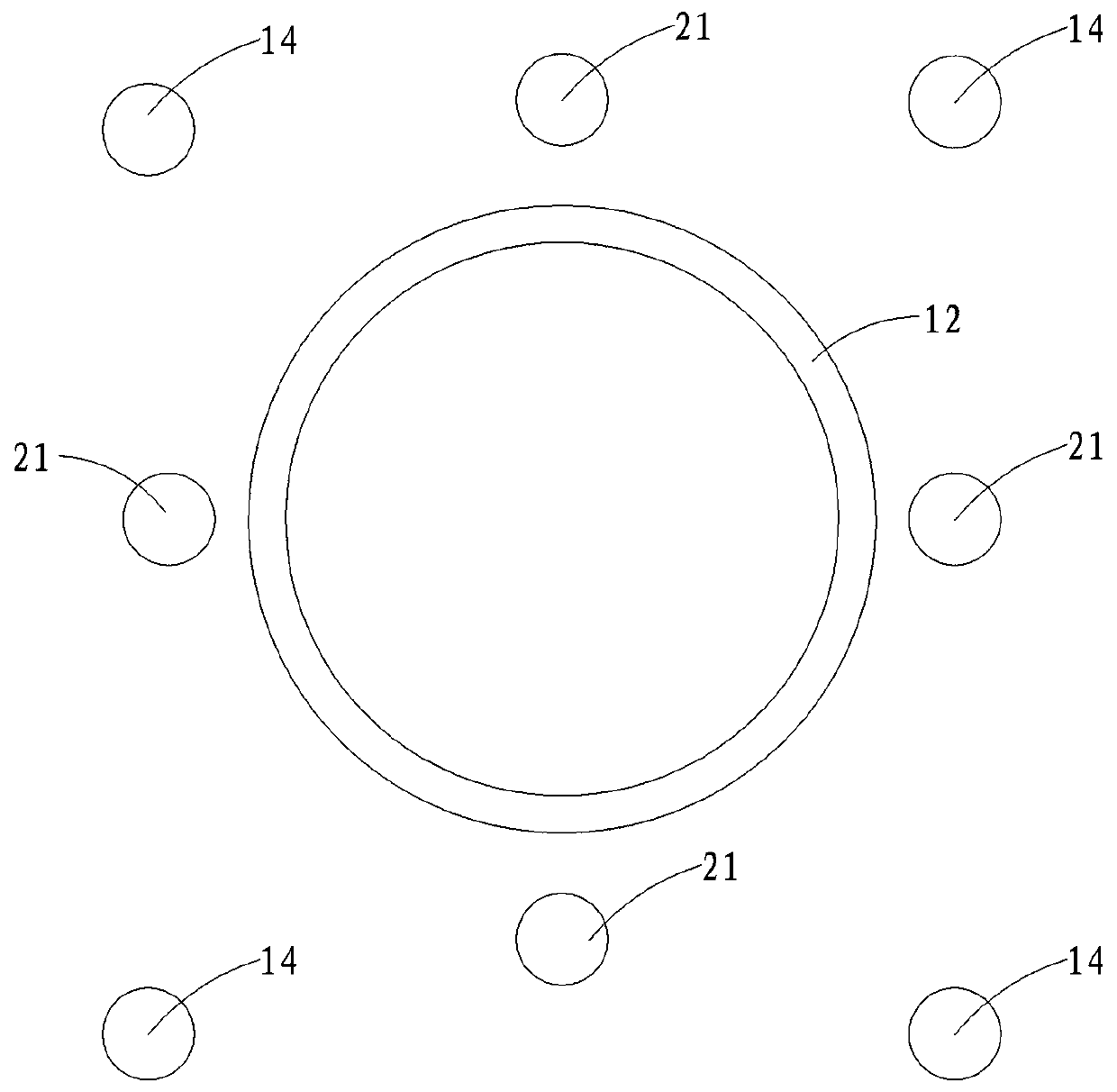

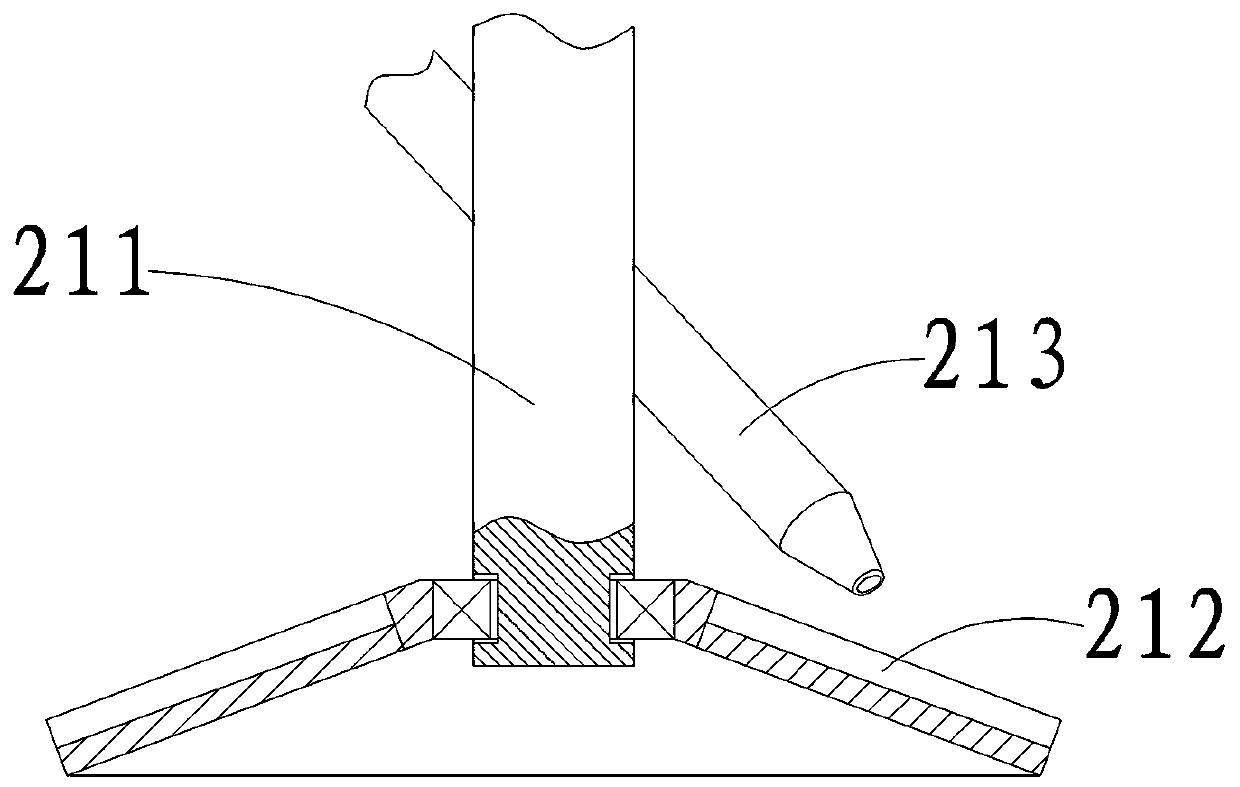

[0035] as attached Figure 1-10Shown, a kind of multi-purpose fiber opening and mixing bin system, opener 71, the mixed cashmere bin communicated with the opener 71 suede outlet and the feeder communicated with the opener 71 entrance; The mixed cashmere bin It includes a velvet outlet mechanism arranged at the bottom of the velvet bin, a velvet inlet pipe 12 arranged at the top of the velvet bin 11, a plurality of breaking heads 21 for blowing the velvet by airflow, and a plurality of atomizing nozzles 14 for spraying functional agents; The breaking head 21 is evenly arranged around the lower end of the down-feeding pipe 12, and a plurality of the atomizing nozzles 14 are evenly arranged around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com