Three-opening hooked opening/closing mould mechanism for injection mould

An injection mold and hook-type technology, which is applied in the field of three-open hook-type mold opening and closing mechanism, can solve the problems of difficulty in improving production efficiency, low production efficiency and high comprehensive cost, and achieve the effect of reducing comprehensive cost and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

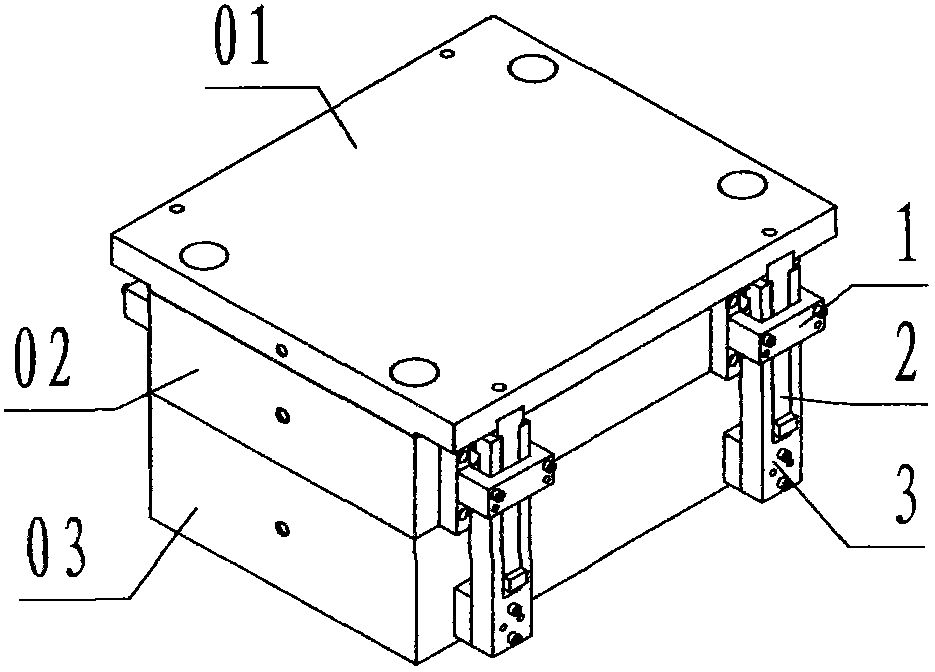

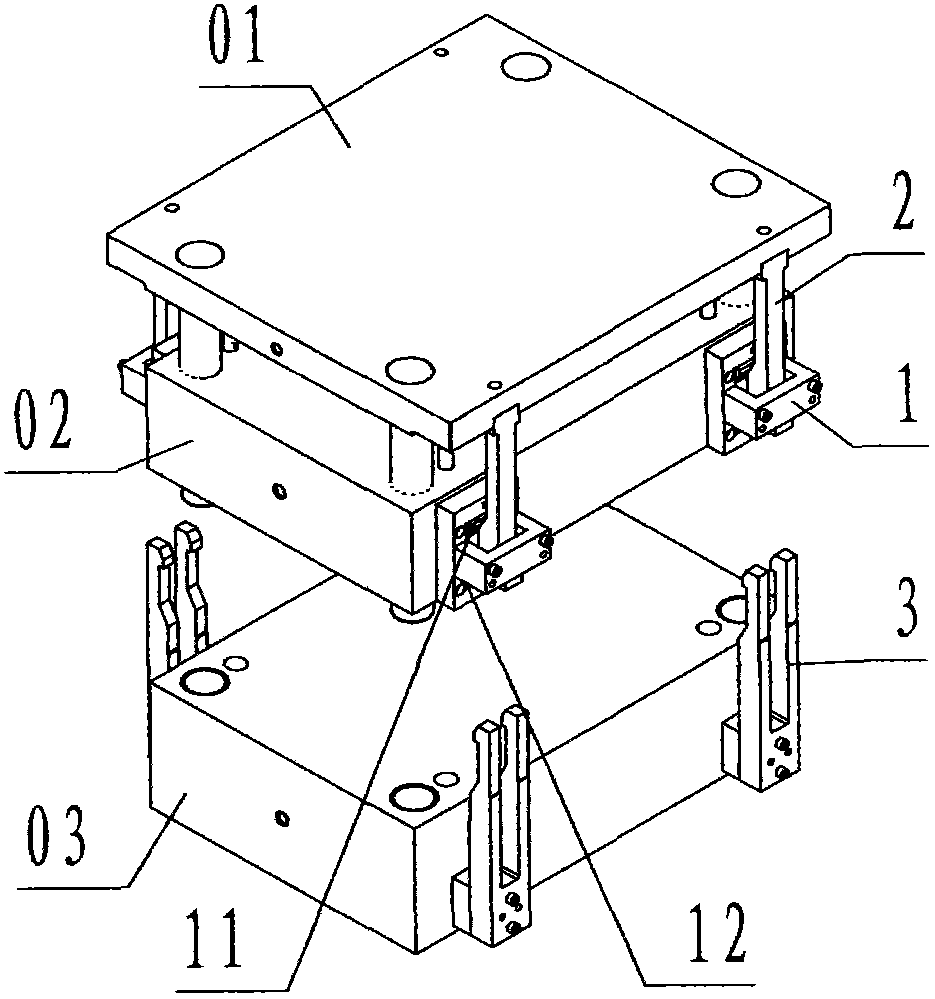

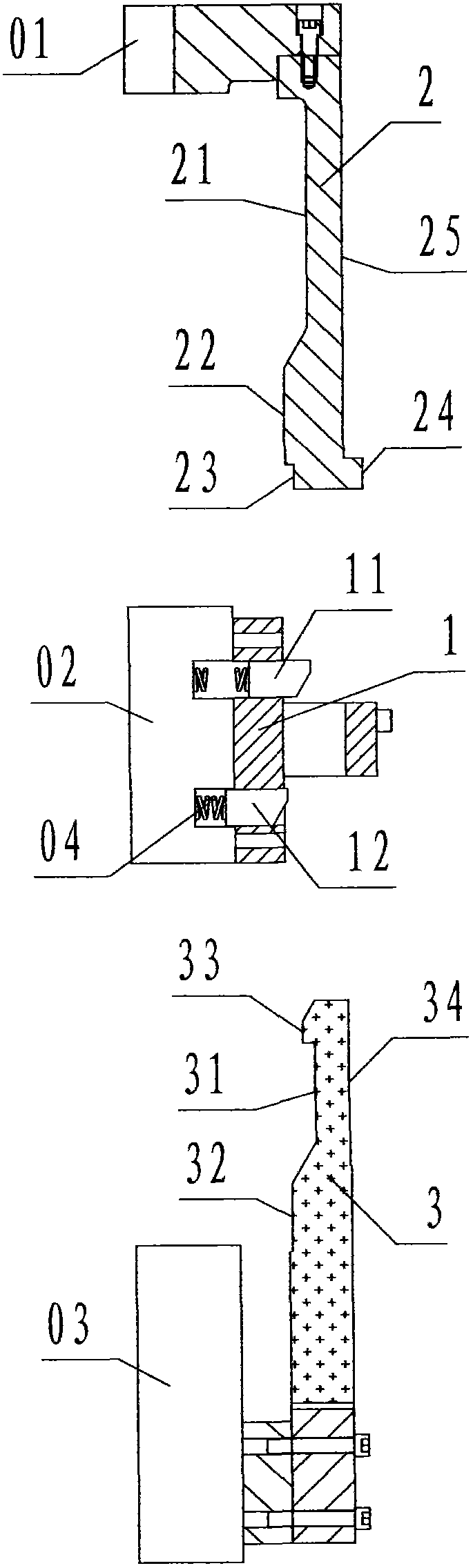

[0029] refer to Figure 1 to Figure 9 , a three-opening hook-type mold opening and closing mechanism for an injection mold of the present invention, including a cavity plate lockway 1, a panel hook 2, and a core plate hook 3. Based on the description of the application mold, the side facing the mold is the inner side, and the side facing the mold The outer side is the outer side, wherein: the inner side of the cavity plate lockway 1 is a rectangular block-shaped base, and the outer side is provided with a protruding rectangular door frame-shaped steel door frame in the center of the base. Components; the outer surface of the base of the cavity panel lockway to the inner wall size of the door frame crossbeam, which is slidingly matched with the thickness of the B step 22 of the panel hook 2; the spacing dimension of the inner wall of the door frame two sides of the cavity panel lockway, and the The overall width of the core board hook 3 is slidably matched; on the base of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com