Folding mechanism with clearance compensation function

A technology of clearance compensation and folding mechanism, applied in special positions of vehicles, vehicle seats, movable seats, etc., can solve the problems of seat shaking, the strength cannot meet the strength requirements, and the hidden safety hazards of passengers, so as to eliminate the front and rear shaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

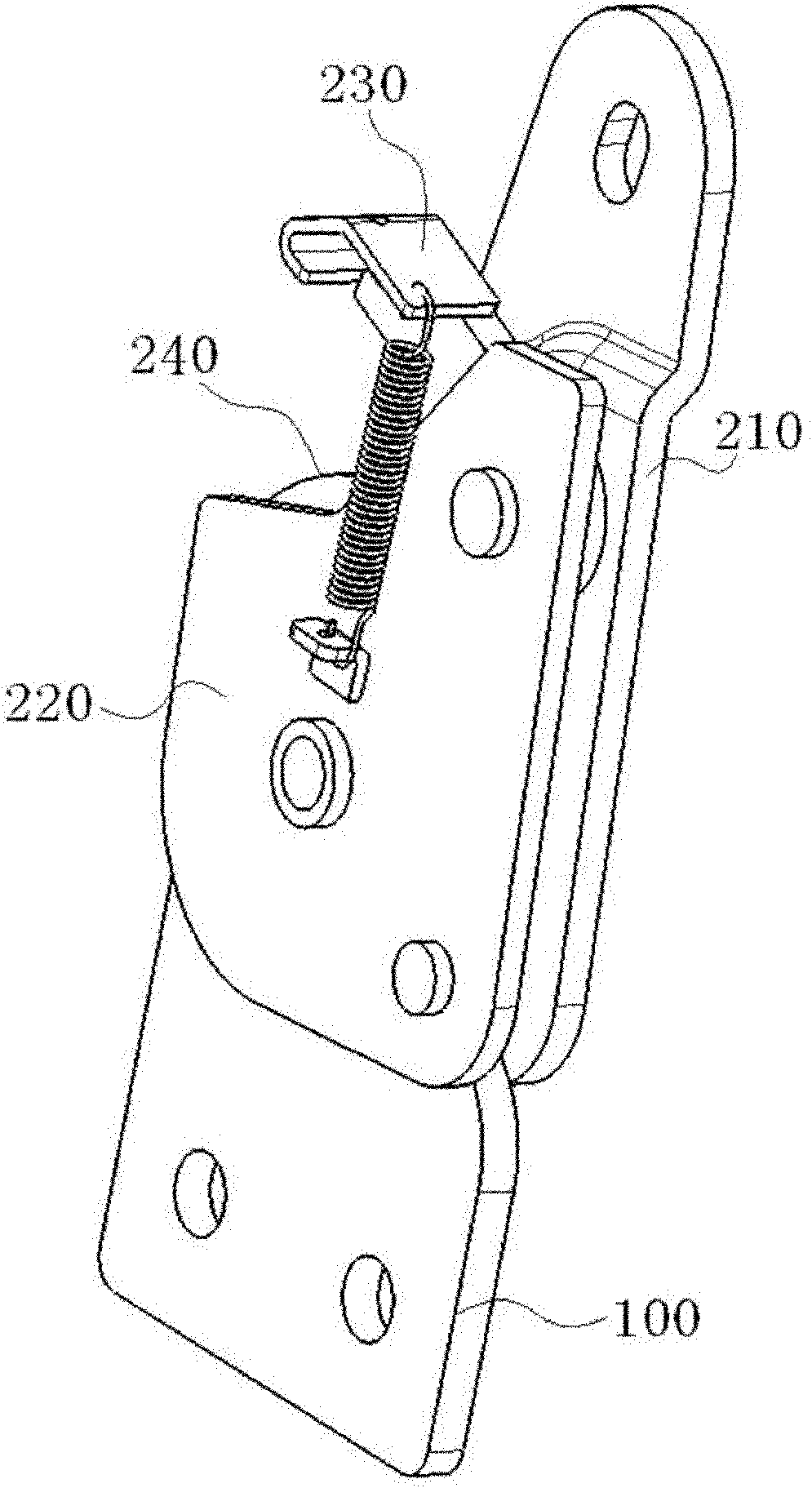

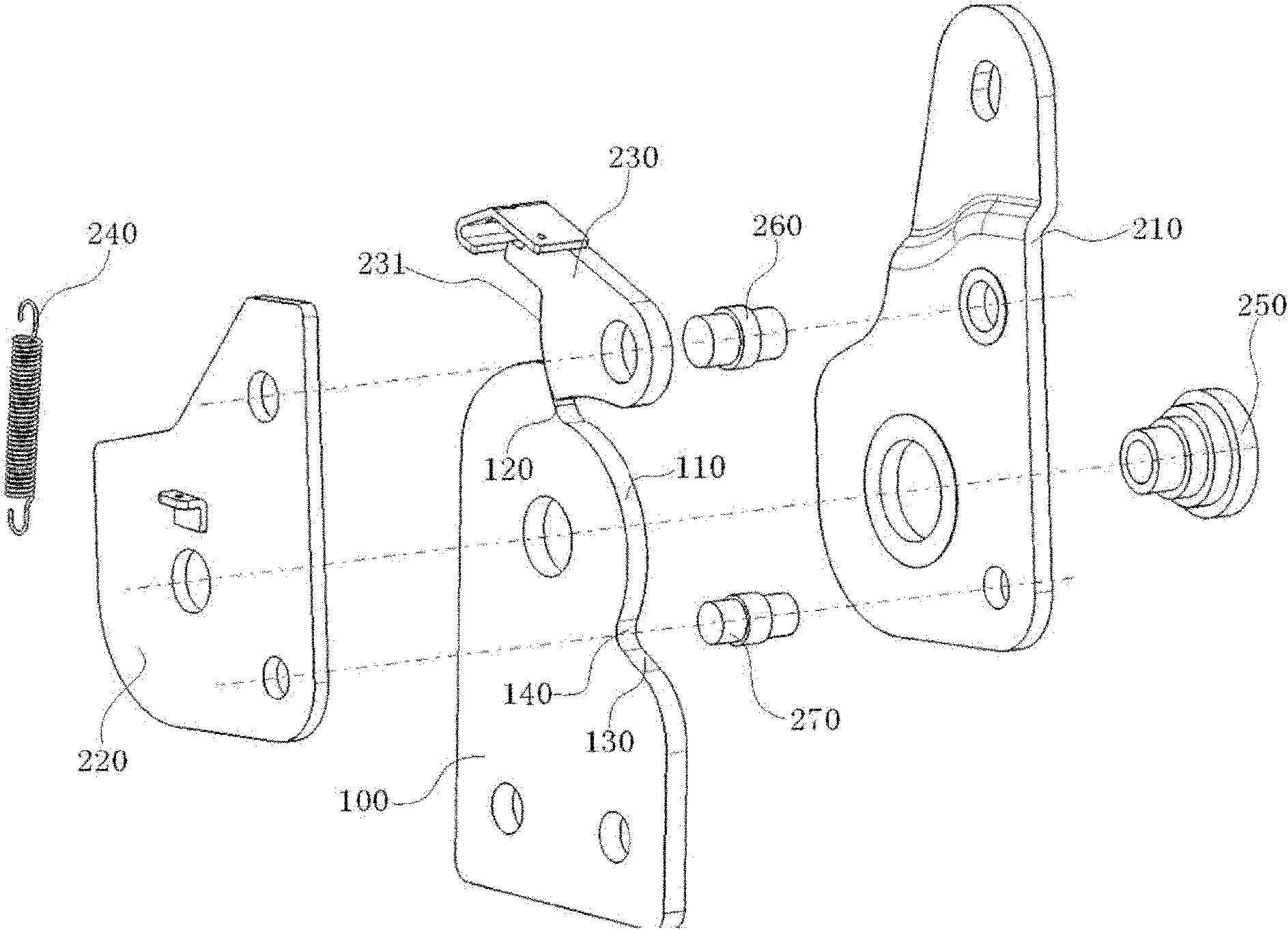

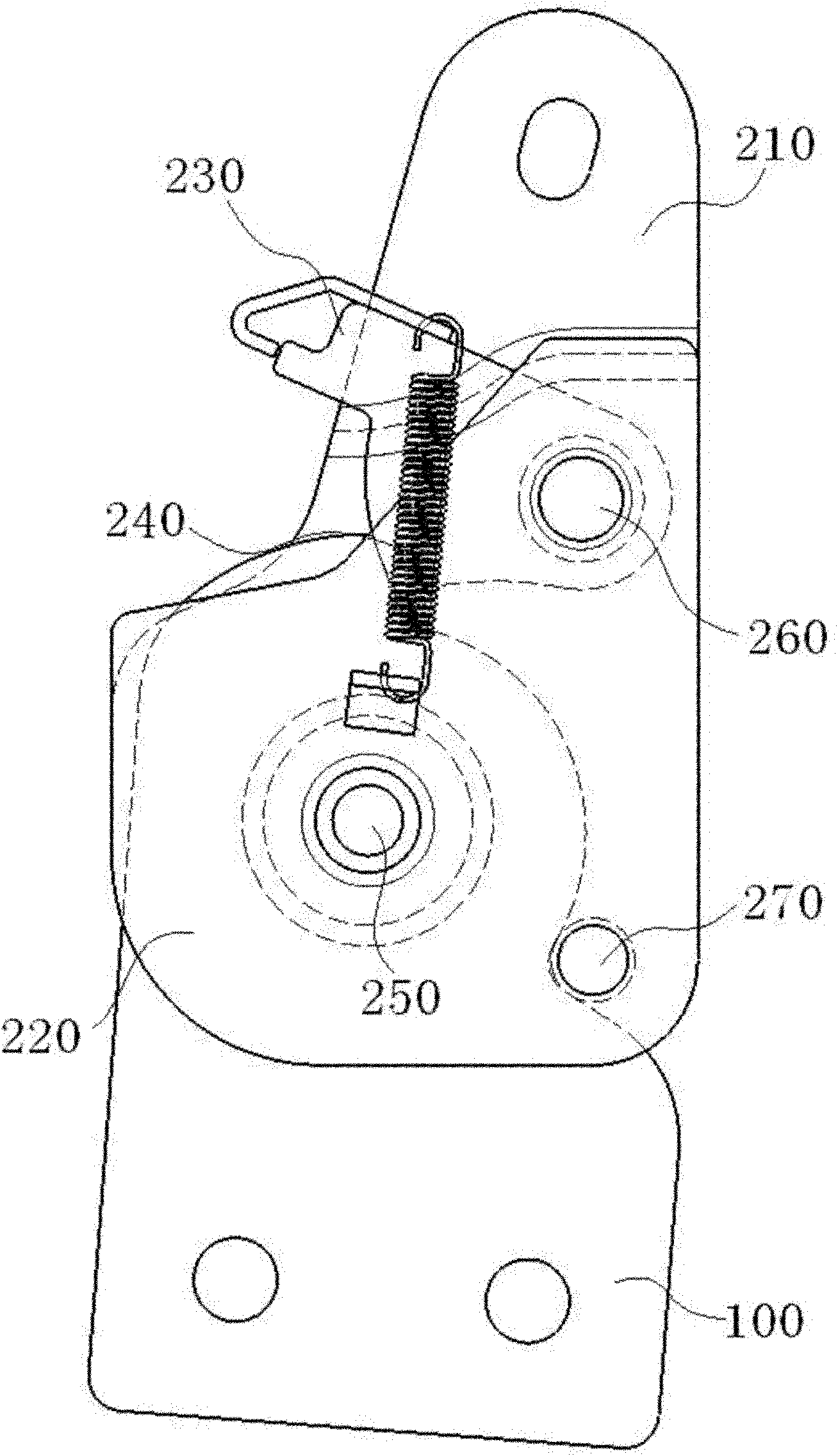

[0027] see figure 1 and figure 2 , the folding mechanism with gap compensation function shown in the figure includes a lower connecting plate 100 connected with the seat cushion frame (not shown in the figure) and a folding and turning assembly.

[0028] The foldable turning assembly includes an inner baffle 210 (the first baffle) connected with the seat back frame (not shown in the figure), an outer baffle 220 (the second baffle), a gap compensation plate 230, a gap Compensation spring 240 . The inner baffle 210 and the outer baffle 220 are rotatably connected to the lower connecting plate 100 through a rotating shaft member, and the lower connecting plate 100 is clamped between the inner baffle 210 and the outer baffle 220 . The rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com