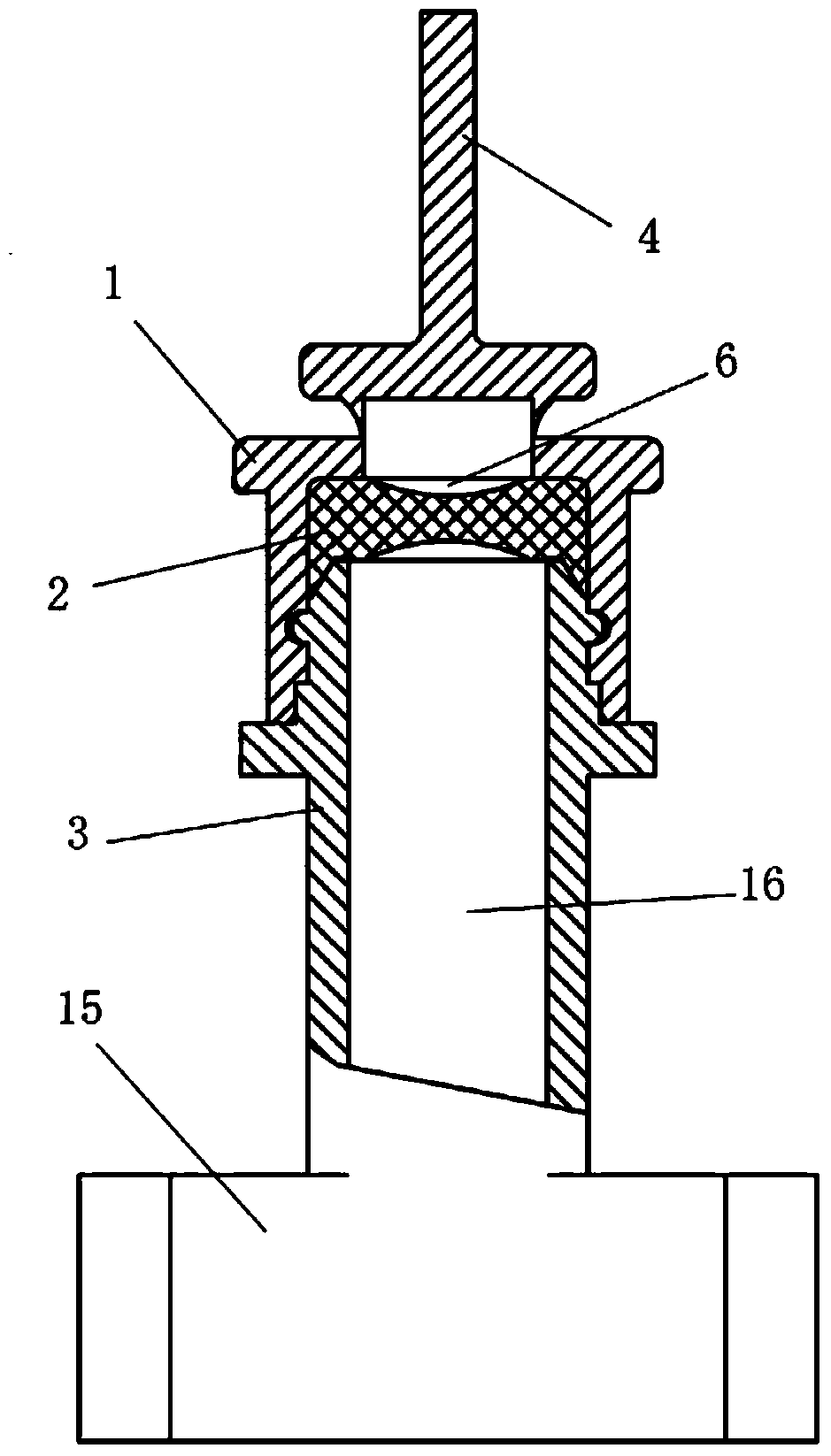

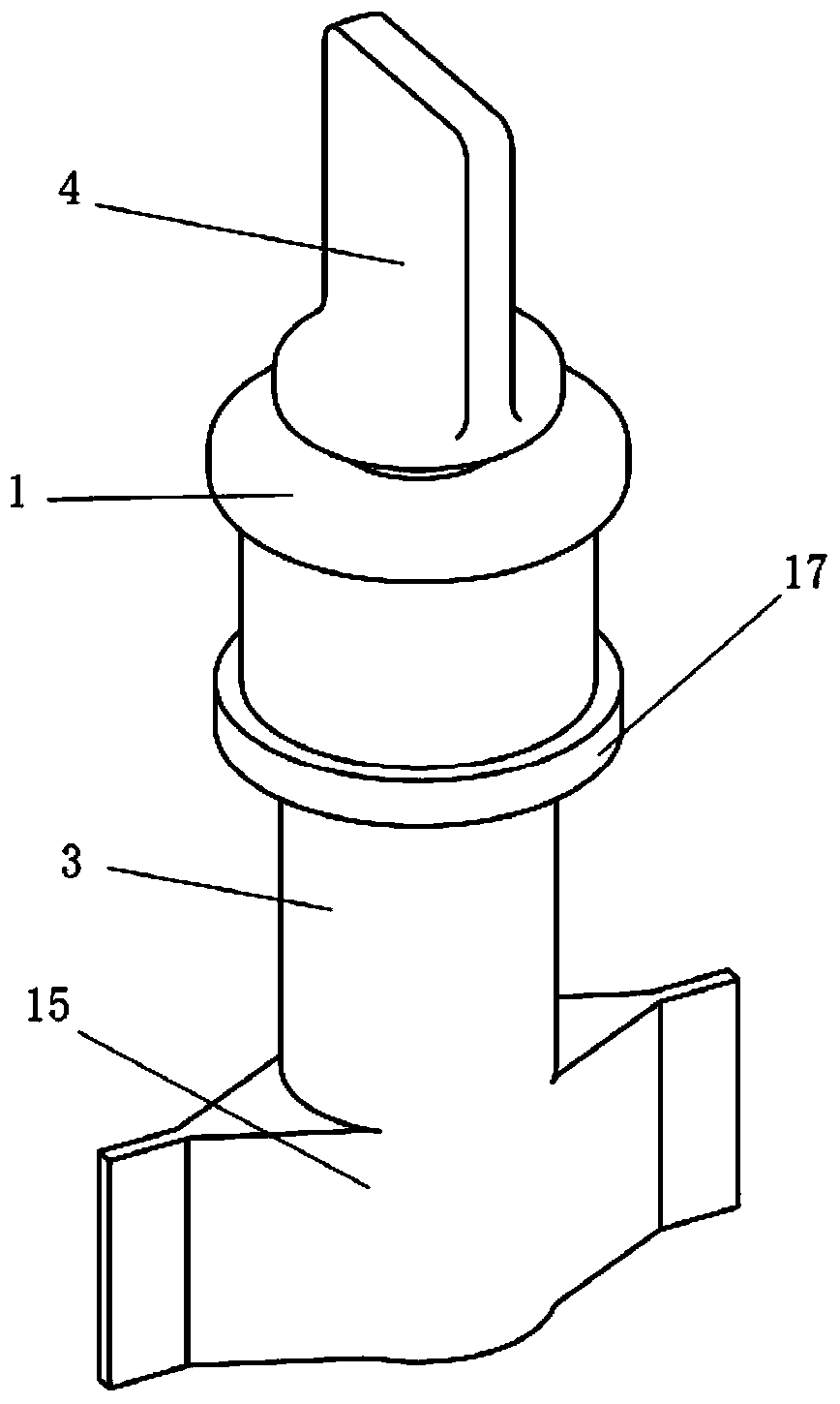

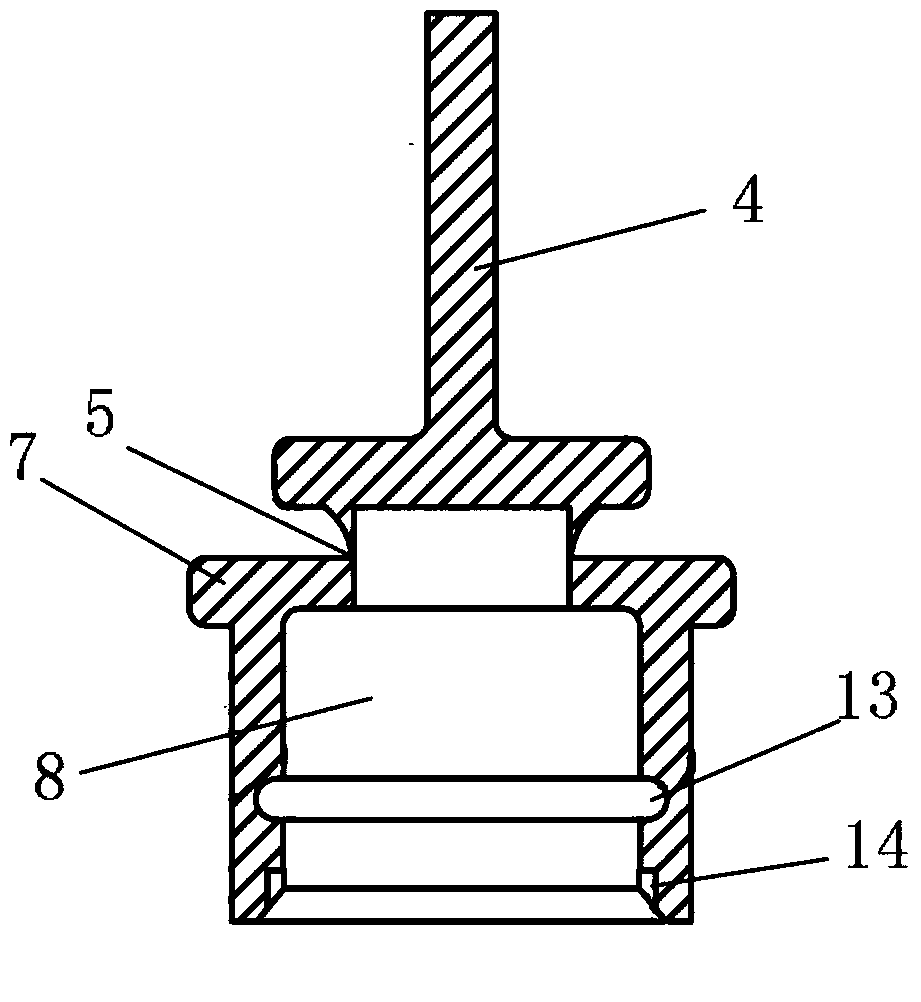

Infusion combined cover with single folded handle and without inner cover, interface, and preparation method thereof

A combined cover and interface technology, applied in the field of medical packaging, can solve the problems of weak connection between the interface and the combined cover, high production cost, complex structure, etc., and achieve the effects of simple and easy preparation process, convenient pin insertion, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of single-folding handle without inner cap type infusion combined cap and interface comprises the following steps:

[0028] Step 1: Mix the outer cover raw materials and outer cover additives to form a uniform mixture, feed the mixture into a twin-screw extruder at 190-230°C, extrude the strands, and cool the strands to 40-60°C ℃, pelletize, and blow dry to obtain the outer cover material, which is injected into the outer cover material according to the shape of the outer cover to obtain the outer cover of the single folding handle type infusion combination cap;

[0029] Step 2: Mix the mixture of interface raw materials and interface additives evenly, feed the mixture into the twin-screw extruder at 190-230°C, extrude the strands, cool the strands to 50°C with water, pelletize, and blow air drying to obtain the interface material and injecting the interface material according to the shape of the interface to obtain the infusion interface.

[003...

Embodiment 1

[0038] First, 45% polypropylene, 15% ethylene-hexene-propylene copolymer, 10% styrene-ethylene-butylene-styrene copolymer, 30% ethylene-propylene copolymer The cover material composed of four (3,5-di-tert-butyl-4-hydroxy) pentaerythritol phenylpropionate, tris (2,4-di-tert-butylphenyl) phosphite, 1,3,5- Trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, β-(3,5-di-tert-butyl-4-hydroxyphenyl)propanoic acid n-deca Octacarbon alcohol ester and hydrotalcite are mixed to form a homogeneous mixture, wherein the weight of the additive is 0.3% of the total weight of the above mixture, and the mixture is fed into a twin-screw extruder at 230°C, and extruded The rods and rods are water-cooled to 50°C, pelletized, and air-dried to obtain the outer cover material, which is injected into the outer cover material according to the shape of the outer cover to obtain the outer cover of the single-fold handle and no inner cover-type infusion combination cap;

[0039] Secondly, the ...

Embodiment 2

[0043] First, 60% polypropylene, 13% ethylene-hexene-propylene copolymer, 7% styrene-ethylene-butylene-styrene copolymer, 20% ethylene-propylene copolymer The cover material composed of four (3,5-di-tert-butyl-4-hydroxy) pentaerythritol phenylpropionate, tris (2,4-di-tert-butylphenyl) phosphite, 1,3,5- Trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, β-(3,5-di-tert-butyl-4-hydroxyphenyl)propanoic acid n-deca Mix additives composed of octacarbon alcohol ester and hydrotalcite to make a homogeneous mixture, wherein the additive weight is 0.2% of the total weight of the above mixture, and feed the mixture into a twin-screw extruder at 200°C, and extrude The rods and rods are water-cooled to 60°C, pelletized, and air-dried to obtain the outer cover material, which is injected into the outer cover material according to the shape of the outer cover to obtain the outer cover of the single-folding handle infusion combination cover;

[0044] Secondly, the raw materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com