Drainage system for overhead bridge

A technology for drainage systems and viaducts, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of blockage of debris in drainage pipes, inconvenient maintenance and dredging, and less collection, to avoid potential safety hazards and increase the effect of aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

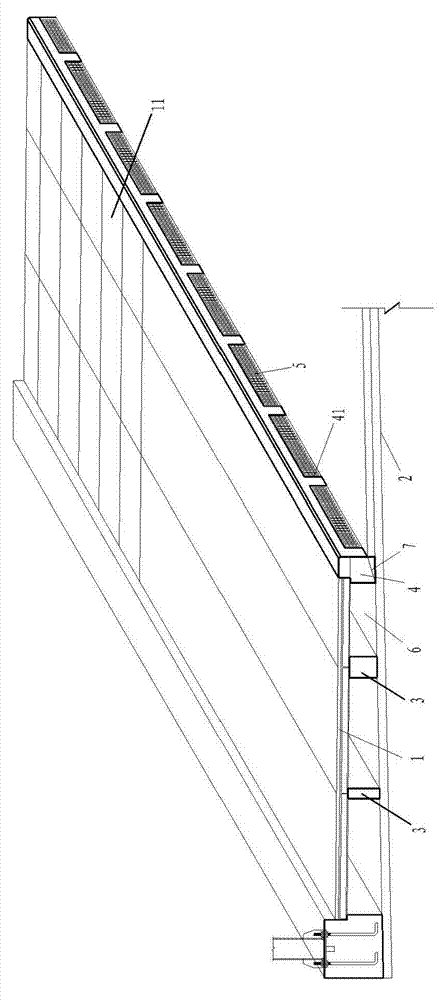

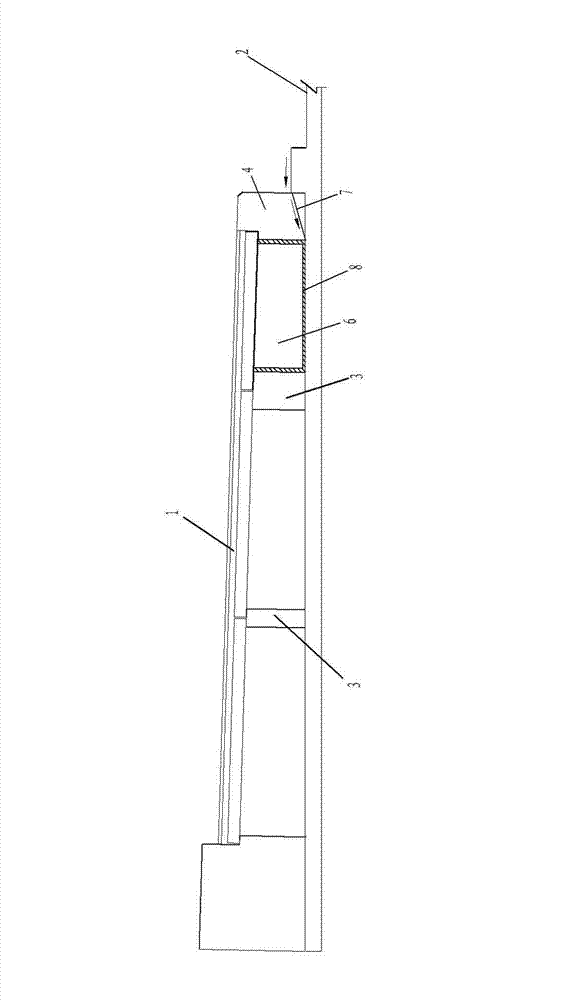

[0020] figure 1 with figure 2 A preferred embodiment of the viaduct drainage system of the present invention is shown. The viaduct includes a sidewalk 1 , a carriageway 2 and a side stone 4 between the sidewalk 1 and the carriageway 2 . The side stone 4 is provided with a through hole 41 for rainwater to flow in, and a water collection and drainage channel 6 extending longitudinally along the sidewalk 1 is provided below the sidewalk 1 . In a specific embodiment, the bottom surface of the through hole 41 on the side stone 4 is set as a diversion slope 7 inclined towards the water collection and drainage channel 6, so as to facilitate the rainwater flowing into the through hole 41 to quickly flow to the water collection and drainage channel 6 . In a specific embodiment, a water inlet grill 5 is arranged in the through hole 41 of the side stone 4 to prevent garbage and sundries from entering the water collection and drainage channel 6 .

[0021] Pad beams 3 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com