Flushing arrangement for a WC and method of operating such a flushing arrangement

A flushing device and pulse technology, applied in water supply devices, flushing toilets, buildings, etc., can solve problems such as the reduction of the acceleration effect of jet nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

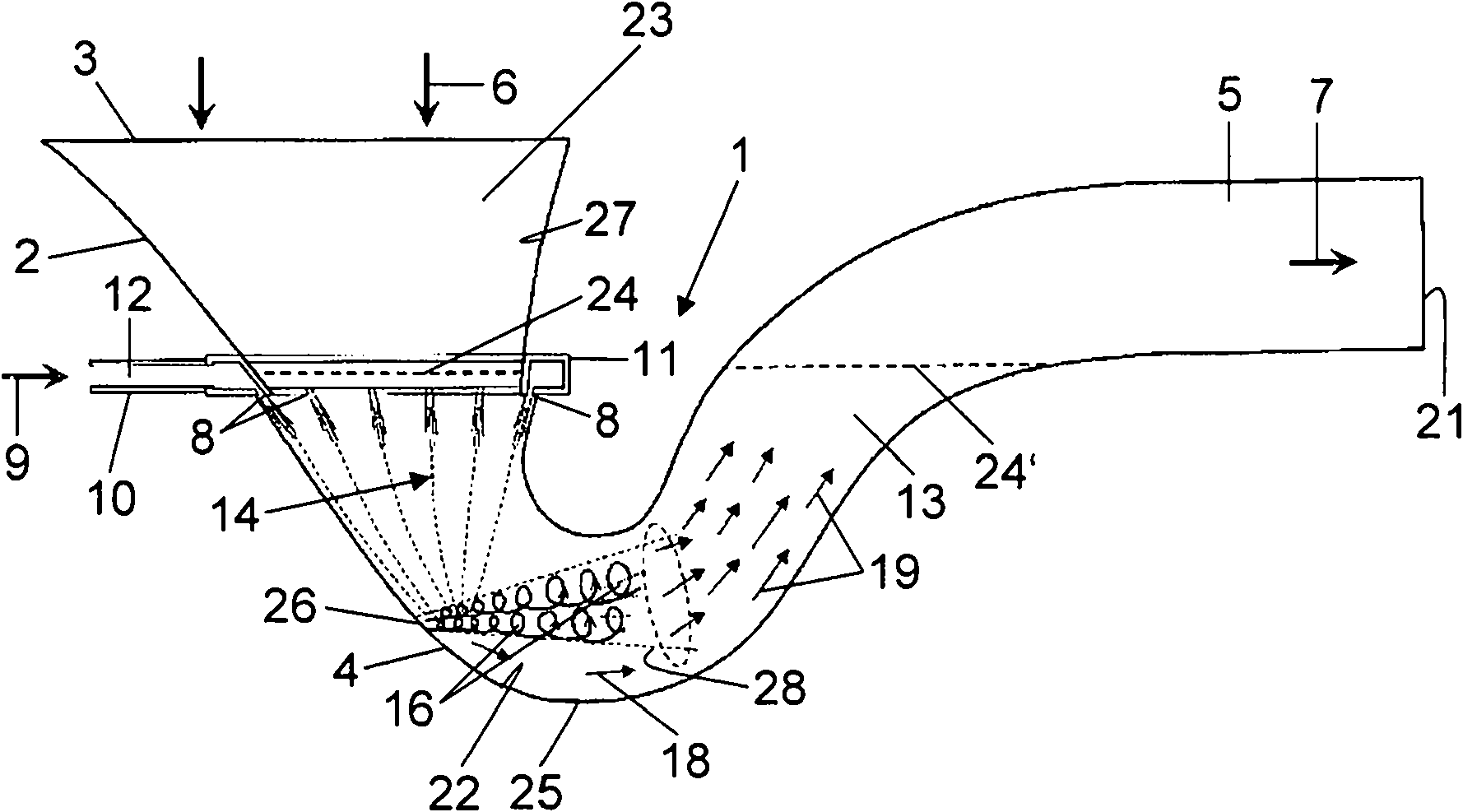

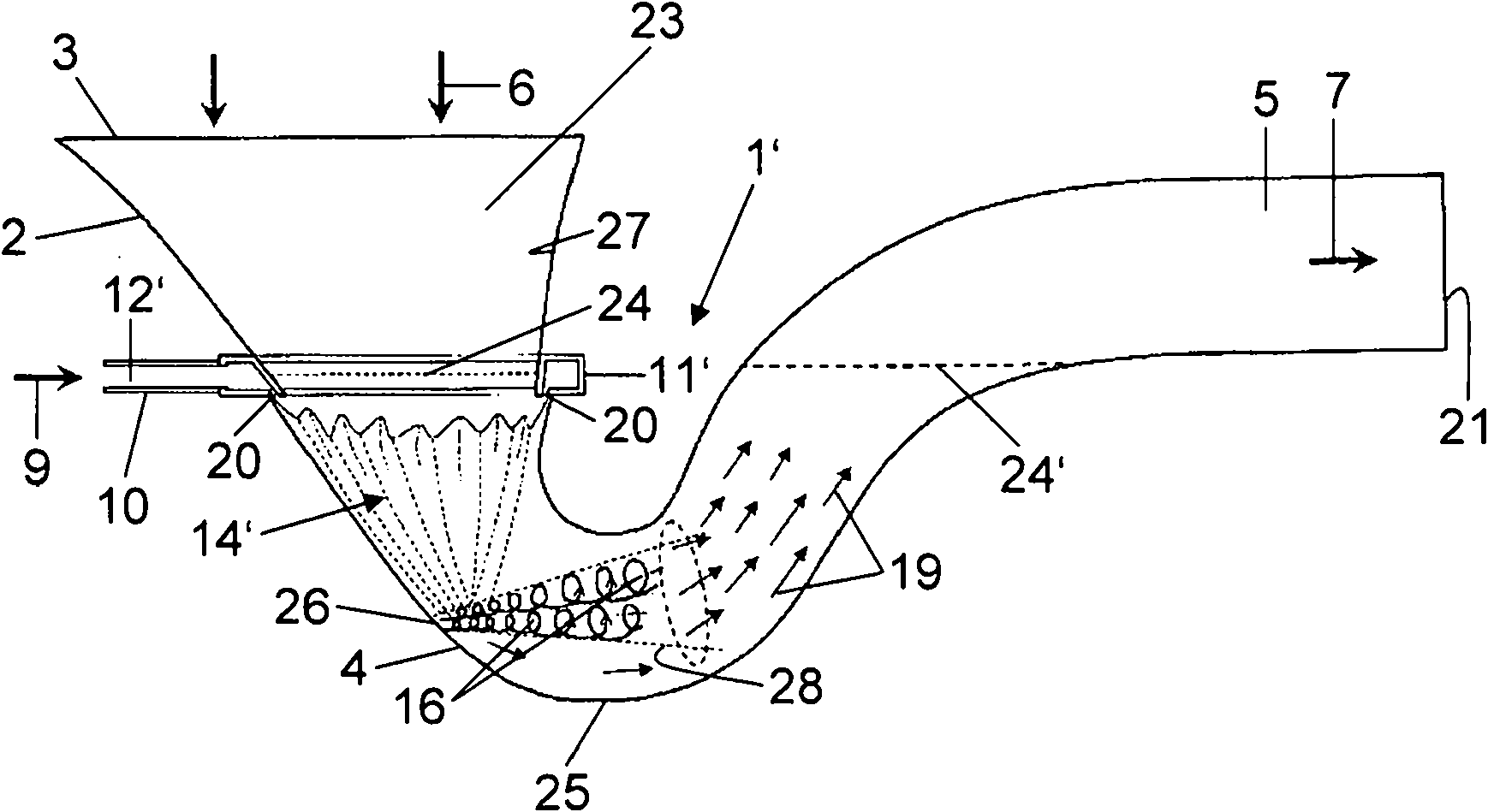

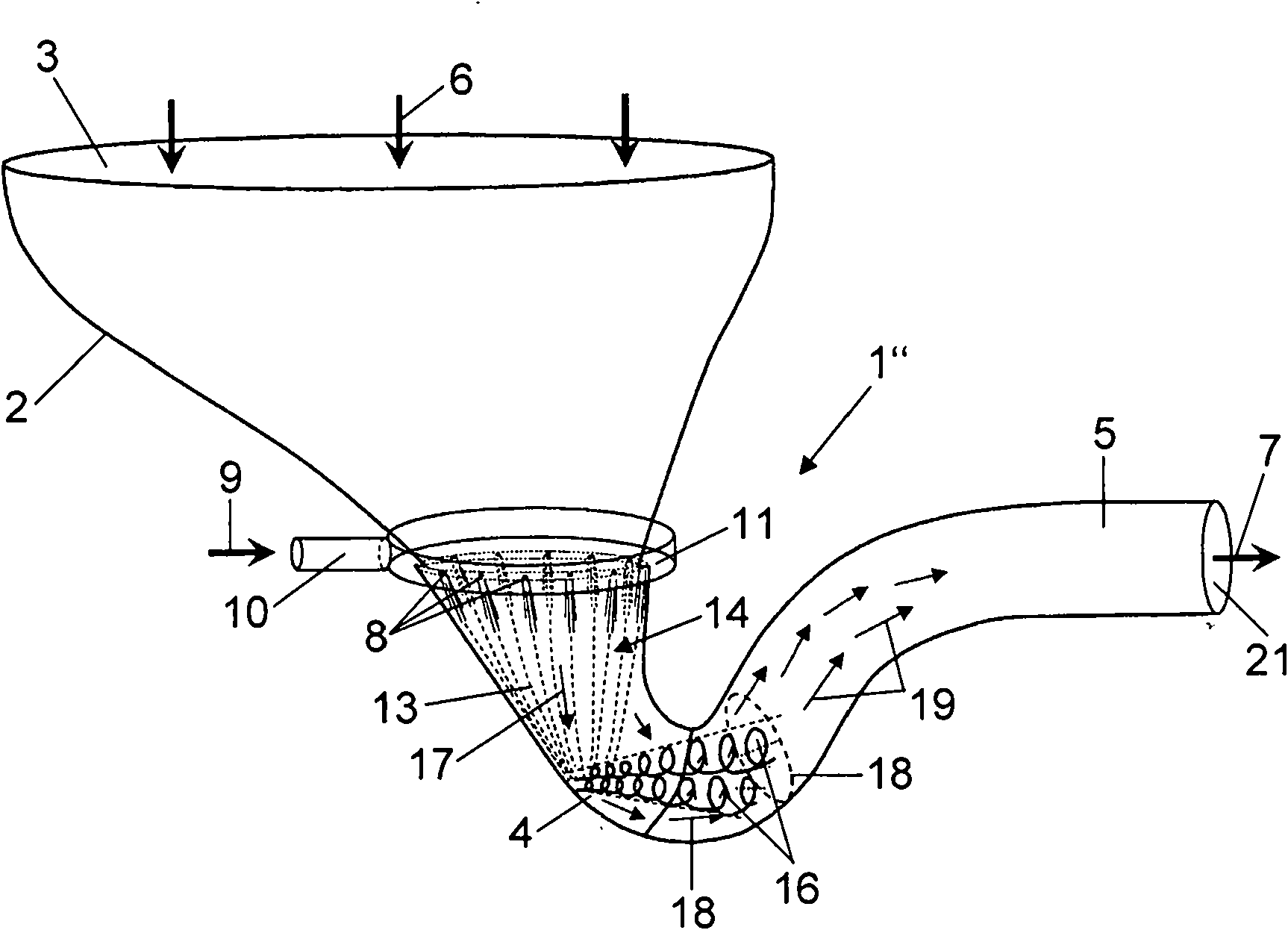

[0018] figure 1 The flushing device 1 shown in has a toilet bowl 2 with an inlet 3 and an outlet 21 . In the domain of the inlet 3 there is a flushing channel (not shown here), known per se, from which water flows during the main flushing along the interior 27 in the direction of arrow 6 downwards to In the U-shaped bending part 4.

[0019] The water 13 located in the U-bend 4 exits from the U-bend 4, leaves the toilet bowl 2 at an outlet 21, and passes from there into a downpipe (not shown here). The toilet bowl 2 therefore has a lowering region which extends as far as the apex 25 of the U-shaped bend 4 . Then start ascending the area. The water 13 forms a U-bend water line 24 in the descending area and a U-bend water line 24' in the ascending area. Of course, the U-bend water lines 24 and 24' are in the same horizontal plane. The water for the main flush originates, for example, from a water reservoir (not shown here) or directly from the water mains.

[0020] The devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com