Flatness absolute checking method based on oblique incidence

An inspection method and technology of oblique incidence, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of reducing test accuracy and unfavorable absolute inspection, and achieve the effect of improving test accuracy and avoiding space consistency errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Use ZYGO GPI-XP interferometer to measure the absolute surface shape distribution of 90mm aluminum-coated mirror, and the working wavelength of the interferometer is λ=632.8nm. The laboratory temperature is 22°, and the temperature is constant for 10 days. Two quartz standard mirrors are used as the reference transmission plane and the reference reflection plane respectively. The two flat crystals have an effective diameter of 102mm and a thickness of 15mm.

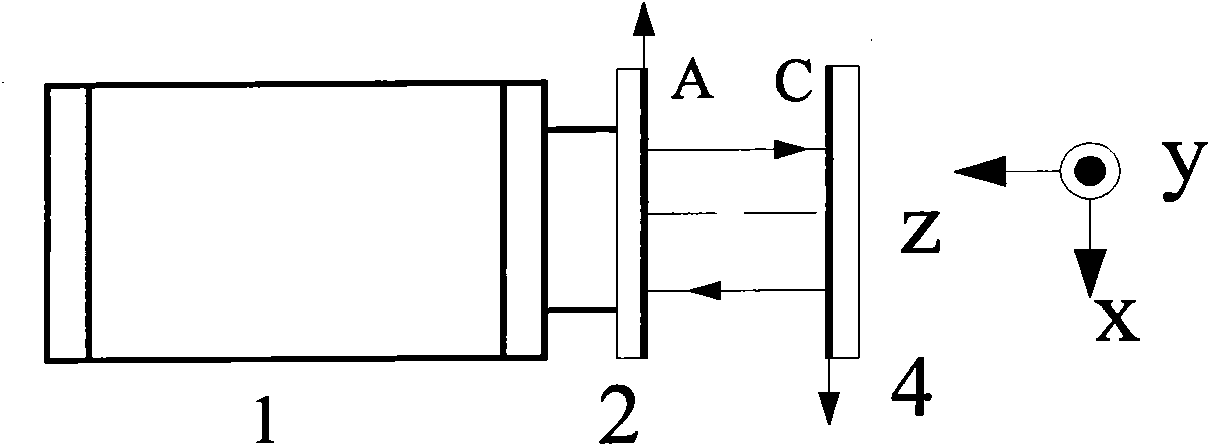

[0056] Step 1: The working surface A of the reference transmissive flat 2 interferes with the working surface C of the reference reflective flat 4 to obtain wavefront data such as Figure 5 shown;

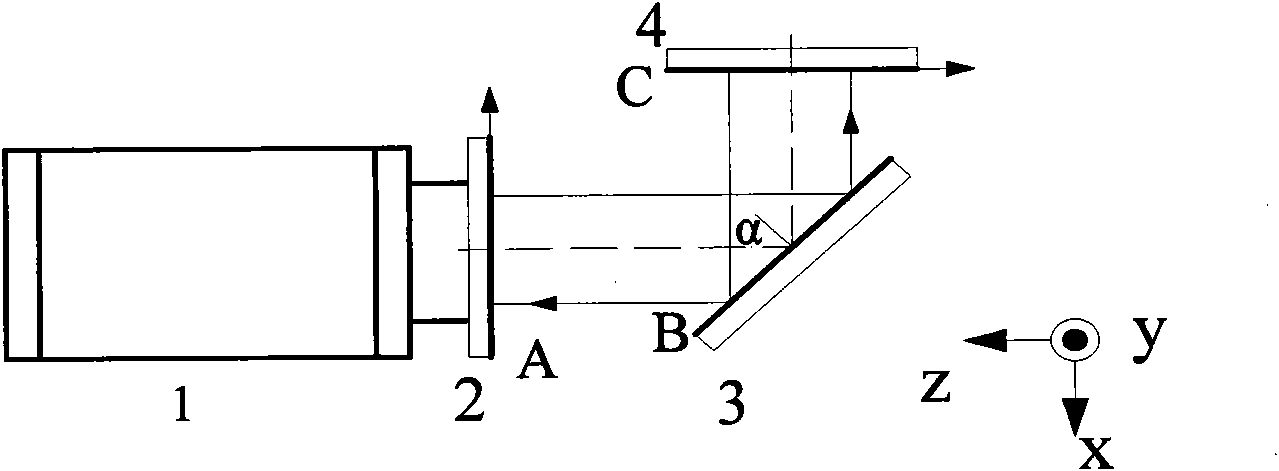

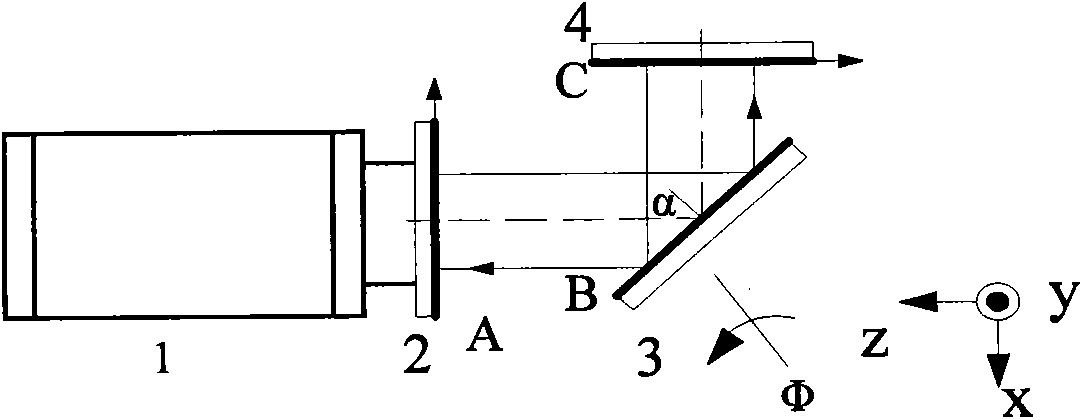

[0057] Step 2: The interferometer collimated wave surface mirror is reflected by the measured surface B after the reference transmission plane exits, and the incident angle is 45°. After self-collimation on the working surface C of the reference reflection plane 4, a test wave surface is formed, which is consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com