Semiconductor mounting structure and method for manufacturing same

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of resin strength, that is, durability and heat resistance, reduction of heat cycle resistance, environmental pollution, etc. problems, to achieve the effect of improving repairability, easy repair, and improving impact resistance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

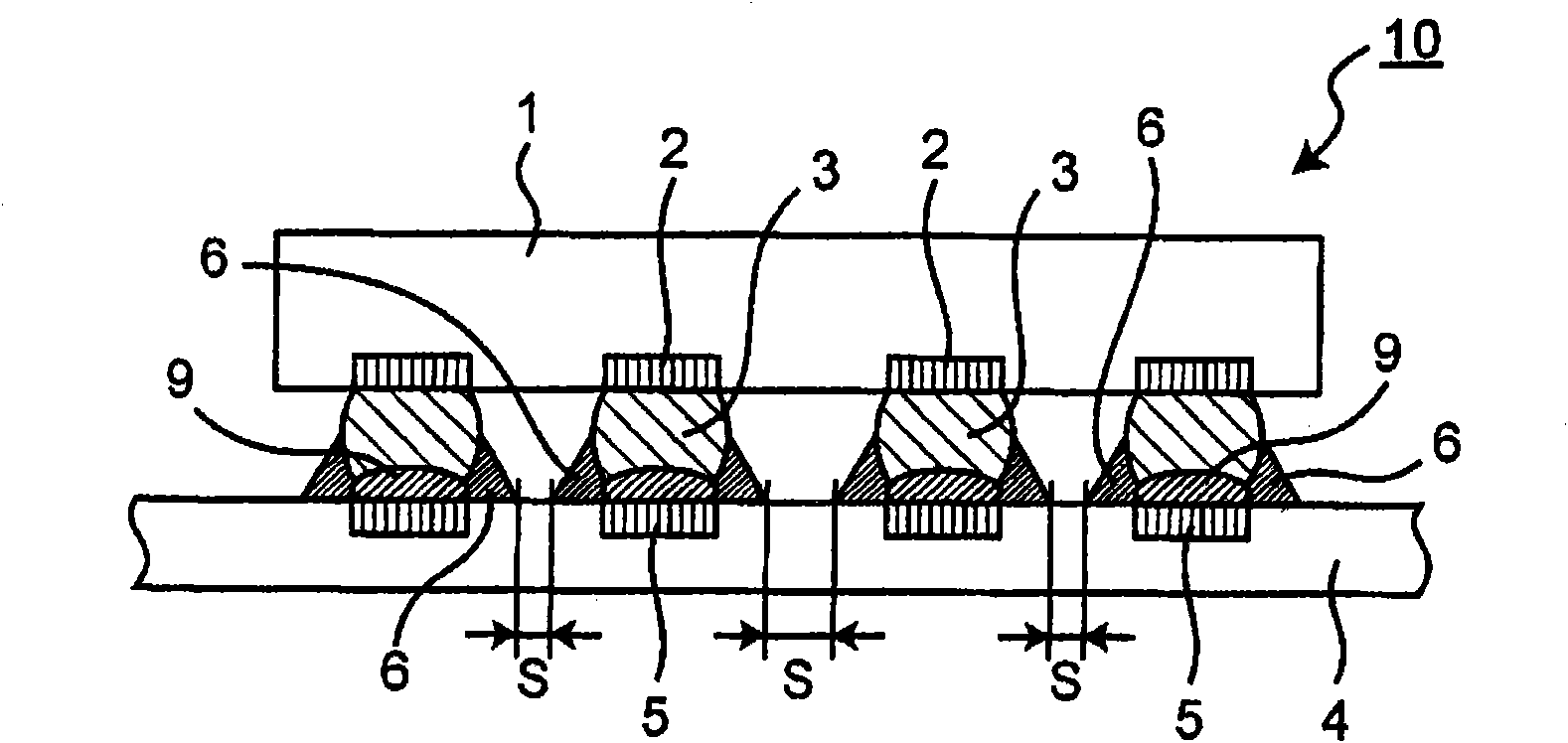

[0038] figure 1 The outline of the mounting structure 10 of the semiconductor package obtained by the mounting method in the first embodiment (an example of a semiconductor includes a case of a semiconductor element alone and a case of a package including a semiconductor element.) 1 Partial sectional view. like figure 1 As shown, the mounting structure 10 includes a BGA semiconductor package 1 having a plurality of electrodes 2 , a solder bump 3 formed on each electrode 2 , and a circuit board 4 having a plurality of substrate electrodes (an example of the second electrode) 5 . , a bonding member 9 that exists between the solder bump 3 and the substrate electrode 5 of the circuit board 4 and electrically connects the solder bump 3 to the substrate electrode 5 , and a reinforcement that is arranged around each bonding member 9 and reinforces the bonding member 9 Resin (reinforced resin member) 6 .

[0039] In the mounting structure 10 of the first embodiment, the solder bump...

no. 2 Embodiment approach

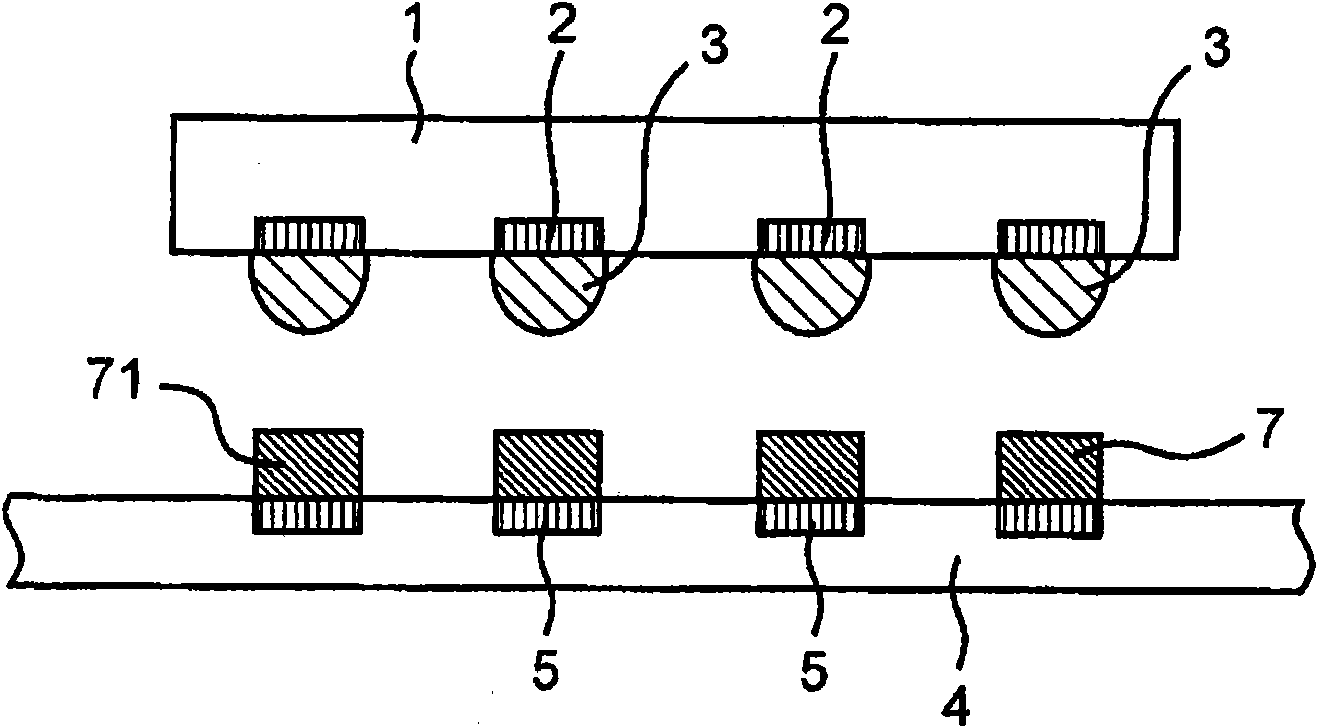

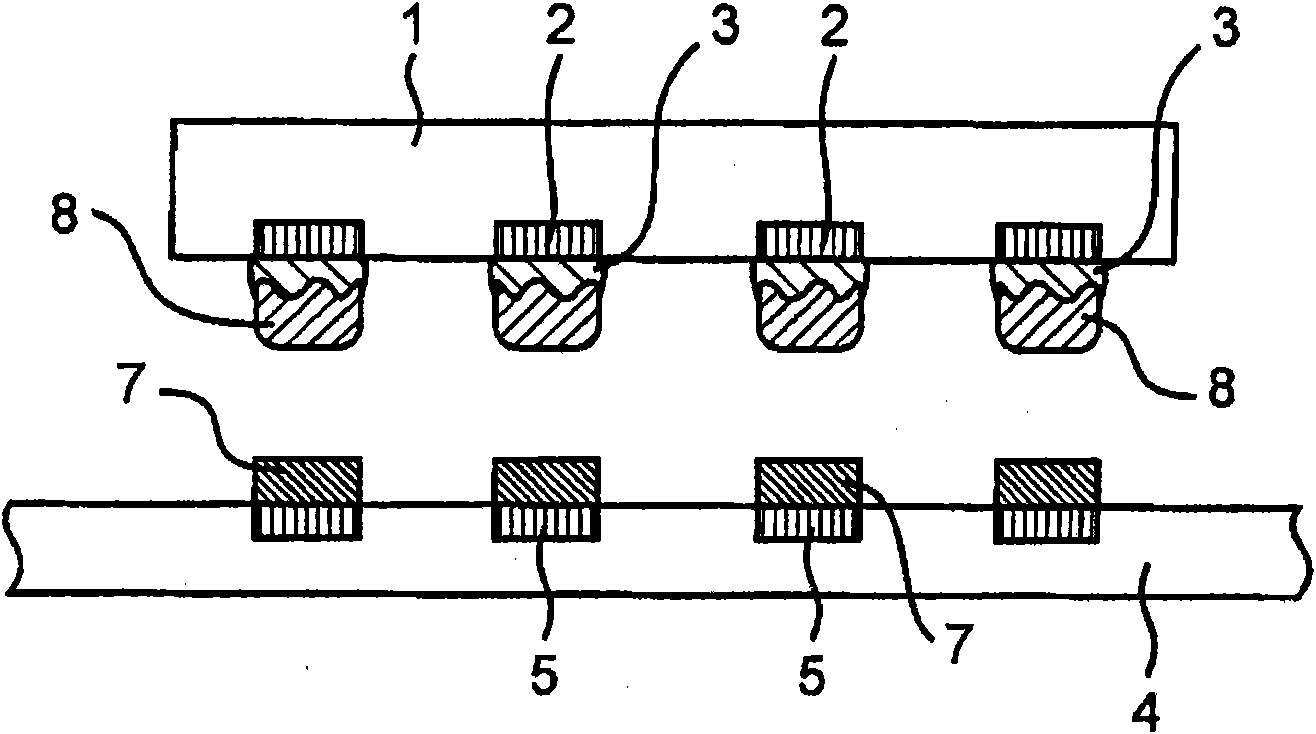

[0053] The second embodiment of the present invention relates to a method of mounting the semiconductor package 1 in one aspect of the present invention, that is, a method of manufacturing the mounting structure 10 of the semiconductor package 1, using figure 2 , image 3 and Figure 4 The mounting methods (manufacturing methods) 1, 2, and 3 of the three patterns will be described. Again, for figure 1 The components of the shown mounting structure 10 that are basically the same are denoted by the same reference numerals, and the description thereof will be omitted.

[0054] (Installation method 1)

[0055] First, the installation method 1 will be described. like figure 2 As shown, a mixed paste 71 (that is, a mixed paste of a solder material and a thermosetting resin) obtained by mixing the following solder material with a thermosetting resin in an uncured state is printed on the substrate electrode 5 of the circuit board 4, so that The solder material is a material co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com