Automatic dust removing system for air filter screen dust

An air filter and automatic dust removal technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., to achieve the effect of simple structure and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

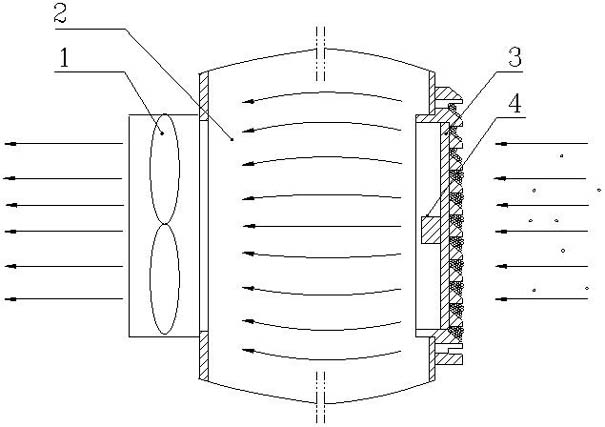

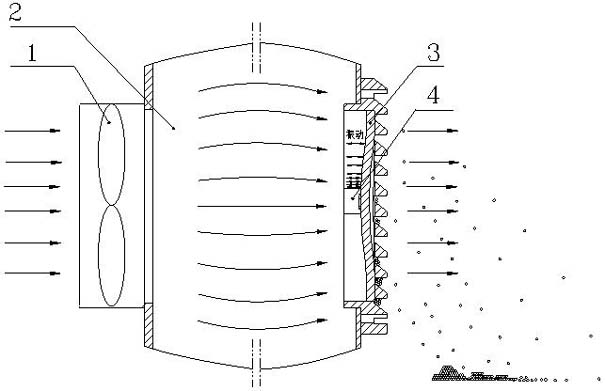

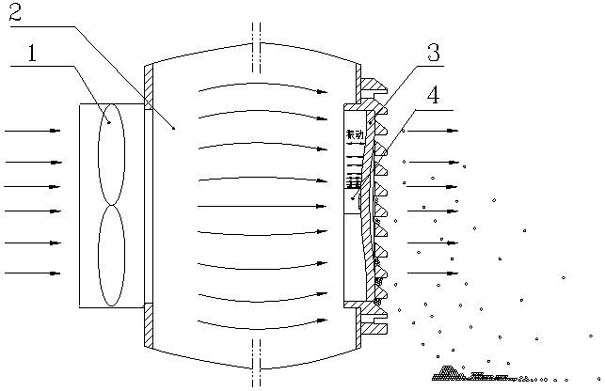

[0011] The dust removal system of the air filter of the present invention includes an air filter and a fan arranged on one side of the confined space, a vibration source is arranged on the air filter, the vibration source is connected with an intelligent control module, and the motor of the fan is simultaneously connected with the intelligent control module. The control modules are connected, and an air flow probe or a dust sensor is arranged on or around the filter, and the air flow probe or dust sensor is connected with the intelligent control module.

[0012] Specifically, the vibration generated by the vibration source driven by the power supply acts on the filter screen at the designated position of the filter screen. The vibration source can be devices such as piezoelectric ceramics, electromagnetic coils, motors with eccentric blocks, and crank linkage mechanisms. When the vibration source is provided with a certain power, the vibration source drives the filter screen to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com