Pulse recoil deashing device special for air purifying equipment and deashing method

A technology of air purification equipment and ash removal device, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of inability to complete filter cartridge ash removal, and achieve the effect of novel structural design and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

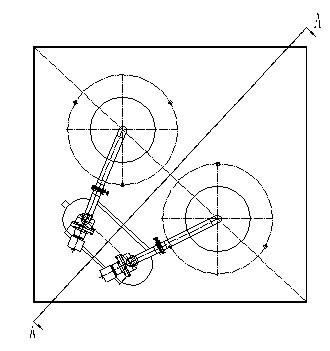

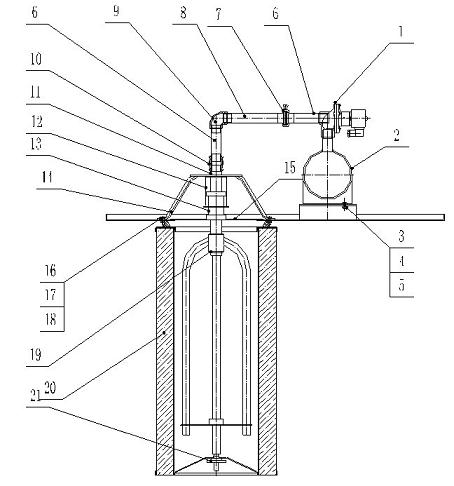

[0012] Embodiment 1: with reference to attached Figure 1-3 . Pulse recoil cleaning device for air purification equipment, which includes air purification and dust removal equipment. The dust removal equipment is equipped with a blowing dust removal system. The sheet 15 is fixed around the hole of the orifice plate, the off-line dust removal cover 15 covers the hole of the orifice plate and is located in the tripod 14, the upper end of the air sleeve 12 is connected with the upper end plate of the tripod 14, and the piston 13 is located in the air sleeve 12 Inside and under the action of gas under pressure, it moves up and down along the inner wall of the air sleeve. The upper end of the piston rod passes through the air sleeve 12 and is in a limited sliding fit with the limit nut 11. The limit nut 11 passes through the air guide tubes 6 and 8, the elbow 9. The clamp quick connection 7 and the pulse solenoid valve 1 are connected with the air bag 2. The air bag 2 is fixed (lo...

Embodiment 2

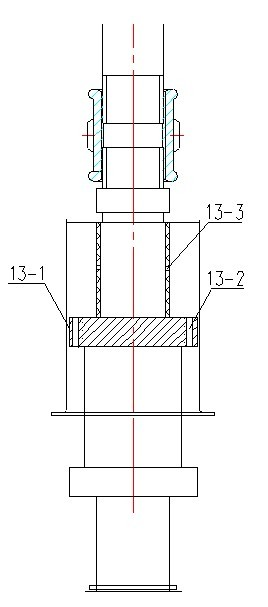

[0016] Embodiment 2: On the basis of embodiment 1, the self-cleaning method of the special pulse recoil dust removal device for air purification equipment, it includes air purification dust removal equipment, when it includes the filter cartridge 20 inner wall in the air purification dust removal equipment needs regeneration At this time, the air source with pressure supplies air to the air bag 2, and the pulse solenoid valve 1 is opened. After the pulsed air flow with pressure enters the piston 13 through the air guide pipes 6 and 8, it enters the blowing rotary frame 19 through the piston all the way, and passes through the piston plug ring all the way. The air hole 13-3 on the upper piston rod enters the air cavity formed by the upper part of the piston plug ring 13-1 and the air sleeve 12 and forces the piston 13 to move up and down according to the pulse air flow, and the piston 13 drives the offline dust cleaning cover 15 to move up and down Simultaneously, the blowing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com