High-efficiency stirring device

A stirring device and high-efficiency technology, which is applied in the field of mixer components, can solve the problems of dead angle and low stirring efficiency in stirring, and achieve the effects of reducing stirring vibration, improving stirring efficiency, and high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

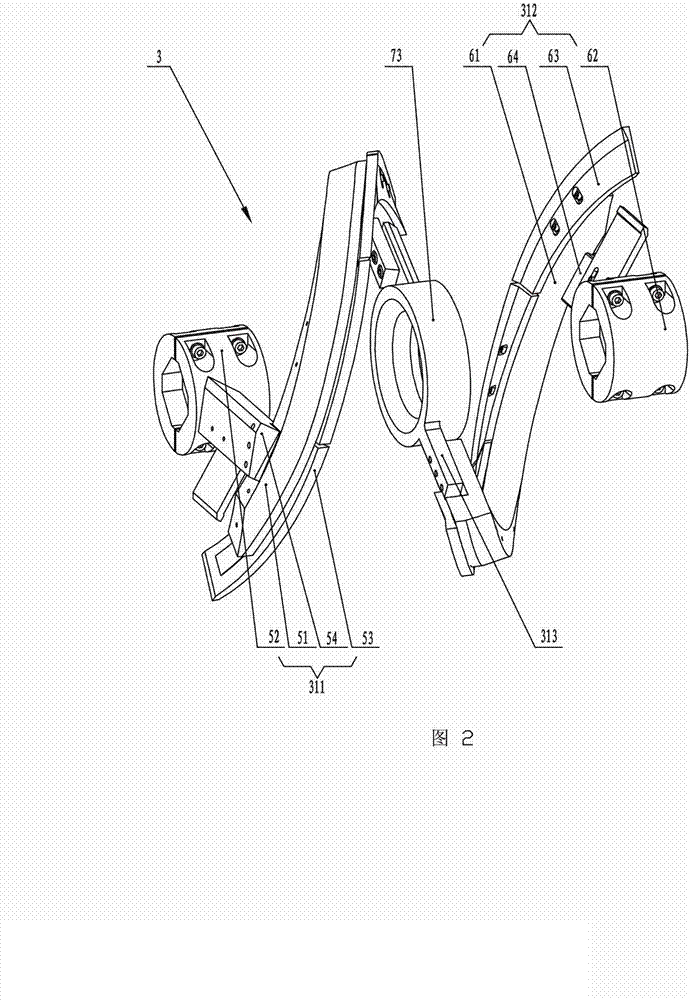

[0017] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

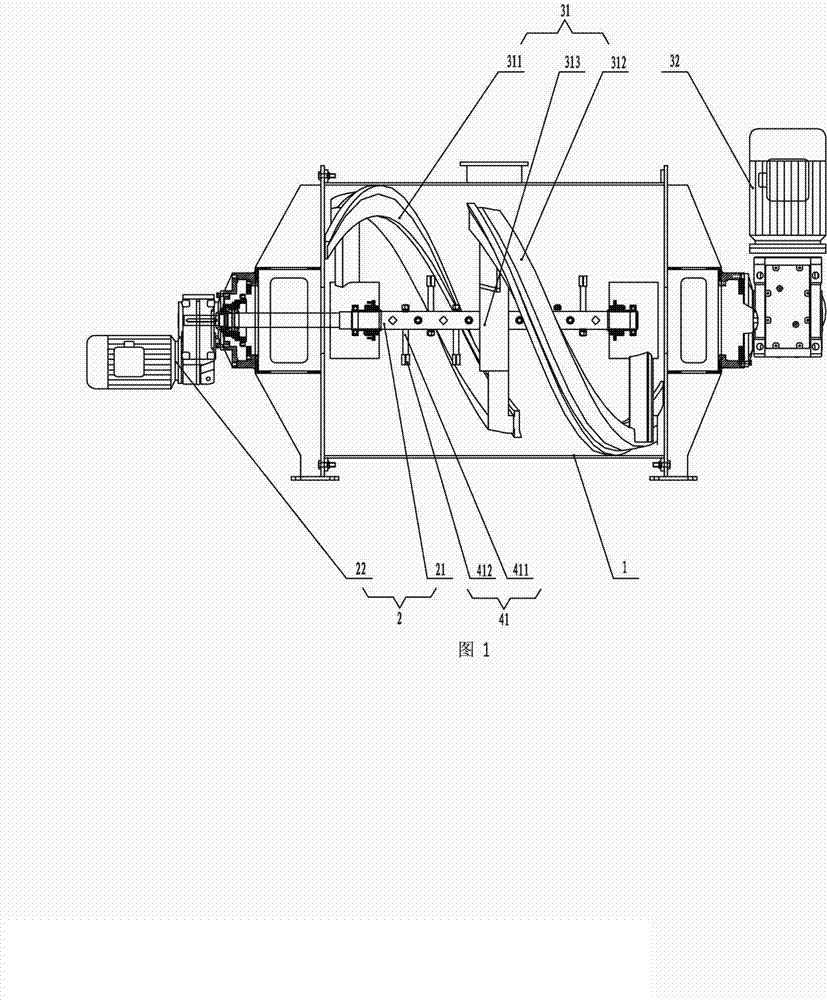

[0018] refer to figure 1 , a high-efficiency stirring device, the stirring device is usually located in the mixer, which is the core component of the mixer, which includes a mixing cylinder 1, an inner stirring device 2 and an outer stirring device 3 that cooperate with each other.

[0019] Continue to refer to figure 1 The inner stirring device 2 includes a stirring shaft 21 extending axially along the stirring cylinder 1 and a forward rotating motor 22 for driving the stirring shaft 21 to rotate. The stirring shaft 21 is mounted in the stirring cylinder 1, and the stirring shaft 21 is spaced Stirring rods 41 are distributed on the ground. The stirring rod 41 is composed of a stirring arm 411 and a volume-enlarging portion 412 disposed on the head of the stirring arm 411 , and the foot of the stirring arm 41 is screwed to the stirring shaft 21 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com