Vacuum stirring system for battery preparation and production

A vacuum stirring and battery technology, applied in the manufacture of electrolyte batteries, secondary batteries, mixer accessories, etc., can solve the problems of insufficient mixing and mixing of battery liquid, low practicability, and qualified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

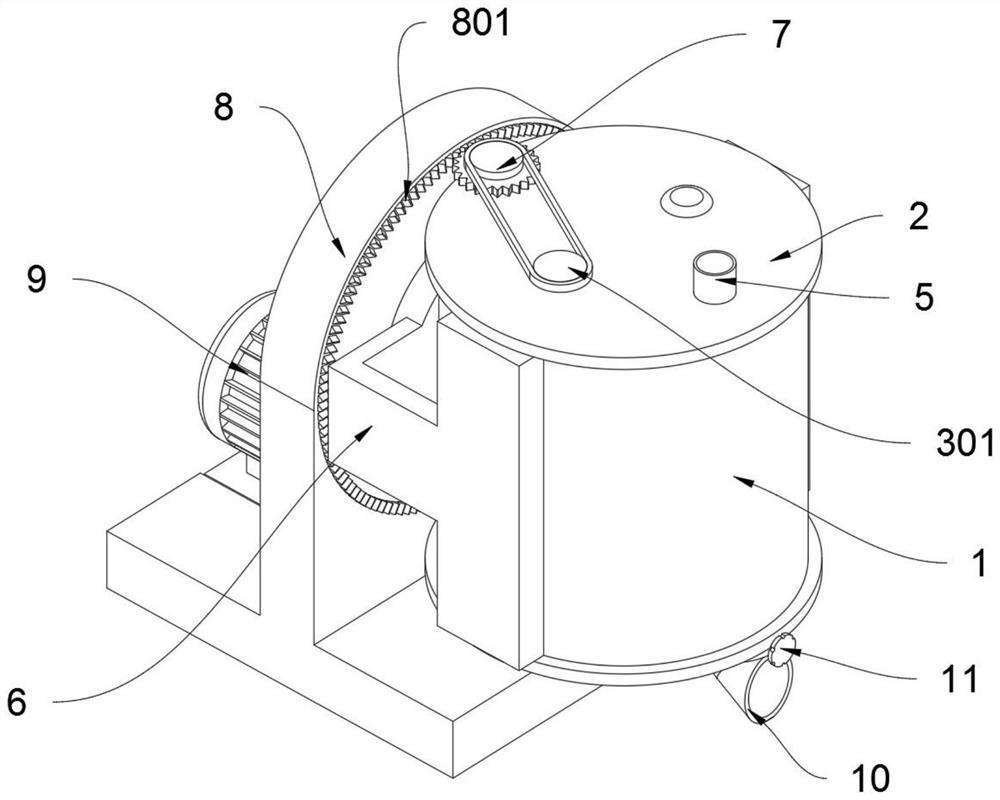

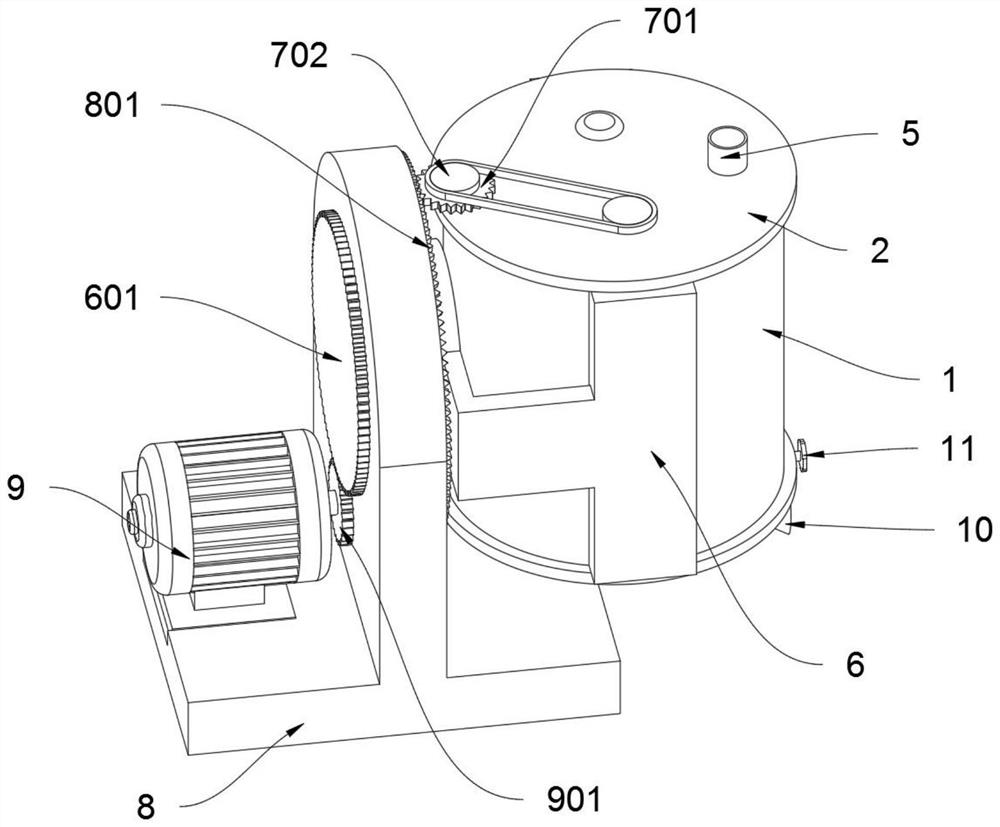

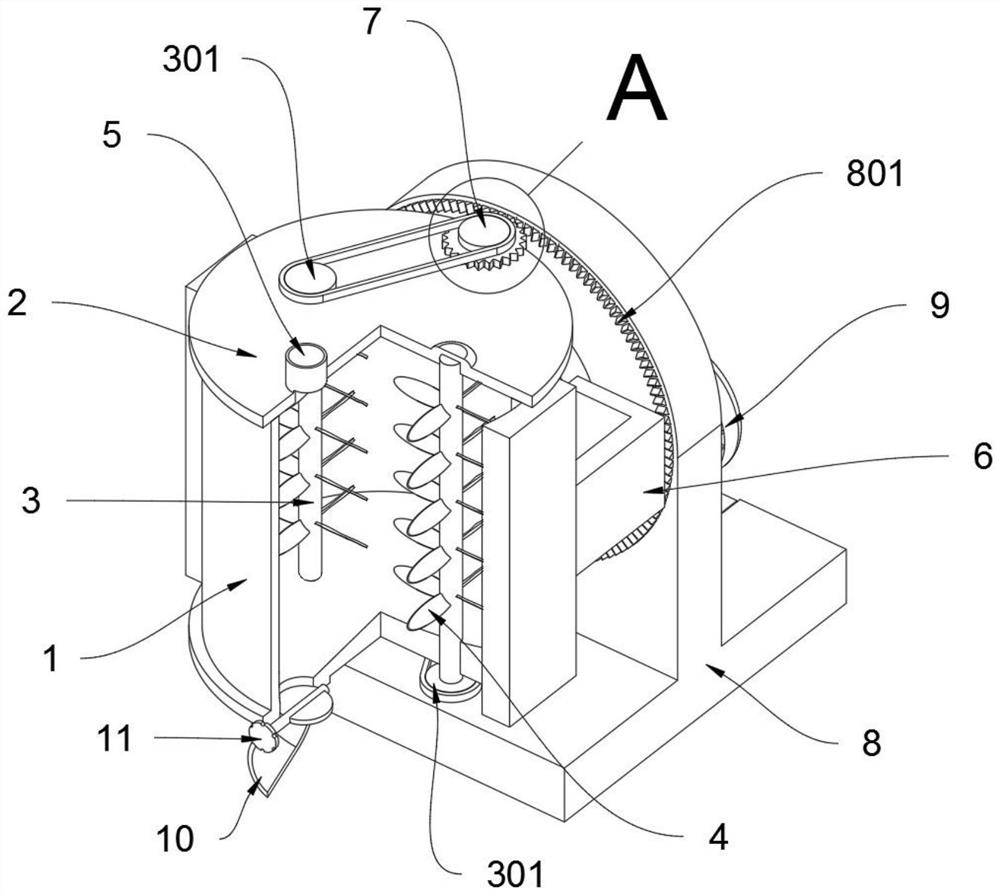

[0034] as attached figure 1 to attach Figure 7 Shown:

[0035]The invention provides a vacuum stirring system for battery production, which includes a top sealing cover 2, a stirring rod 3, a stirring hinge 4, a vacuum control valve 5, a fixed bracket 6, a composite transmission wheel 7, a driving motor 9, and a discharge pipe 10 and on-off valve 11; the top sealing cover 2 is plugged into the top of the vacuum mixing tank 1; the bottom end of the stirring rod 3 is connected to the bottom of the vacuum mixing tank 1, and the top of the stirring rod 3 is connected to the top sealing cover 2 Stirring rotary leaf 4 is fixedly connected to the outside of the rod body of stirring rod 3; Vacuum control valve 5 is fixedly connected to one side of the top sealing cover 2 cover body top, and vacuum control valve 5 is connected to external vacuum equipment through connecting pipes; The fixed bracket 6 is connected to the middle part of the fixed base 8 vertical plate body by rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com