Pipe clamp type temperature controller

A temperature controller and tube clamp technology, which is applied in the direction of temperature control using electric methods, can solve problems such as inability to install, thread slippage, cumbersome installation, etc., achieve simple and easy installation and disassembly, improve assembly efficiency, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

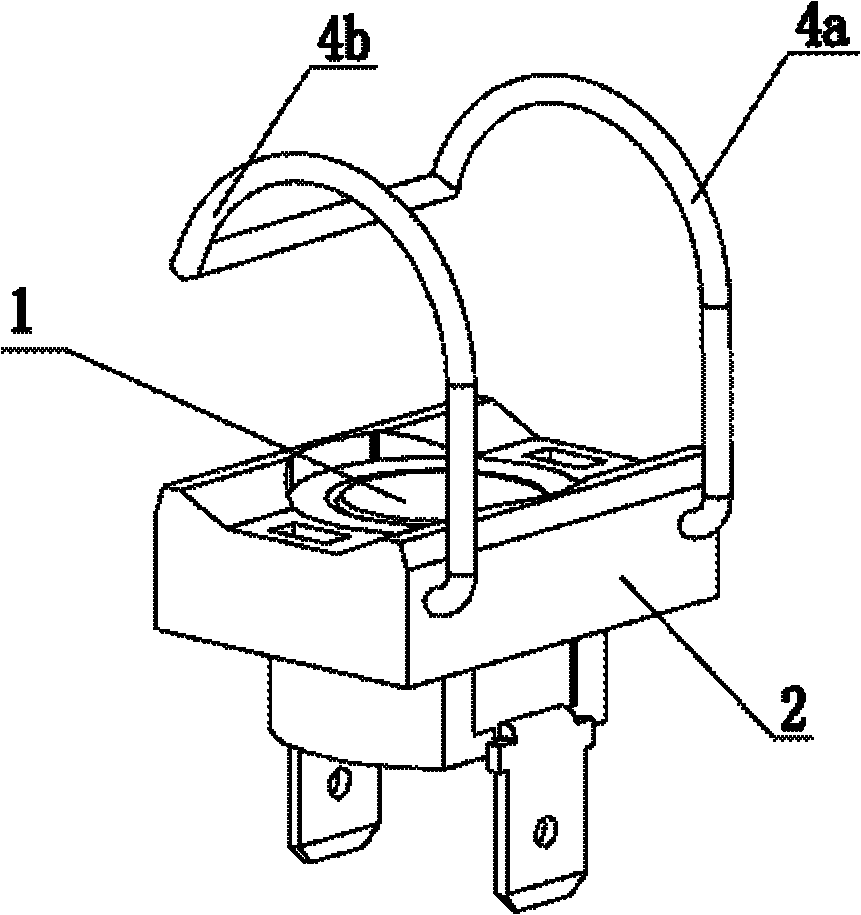

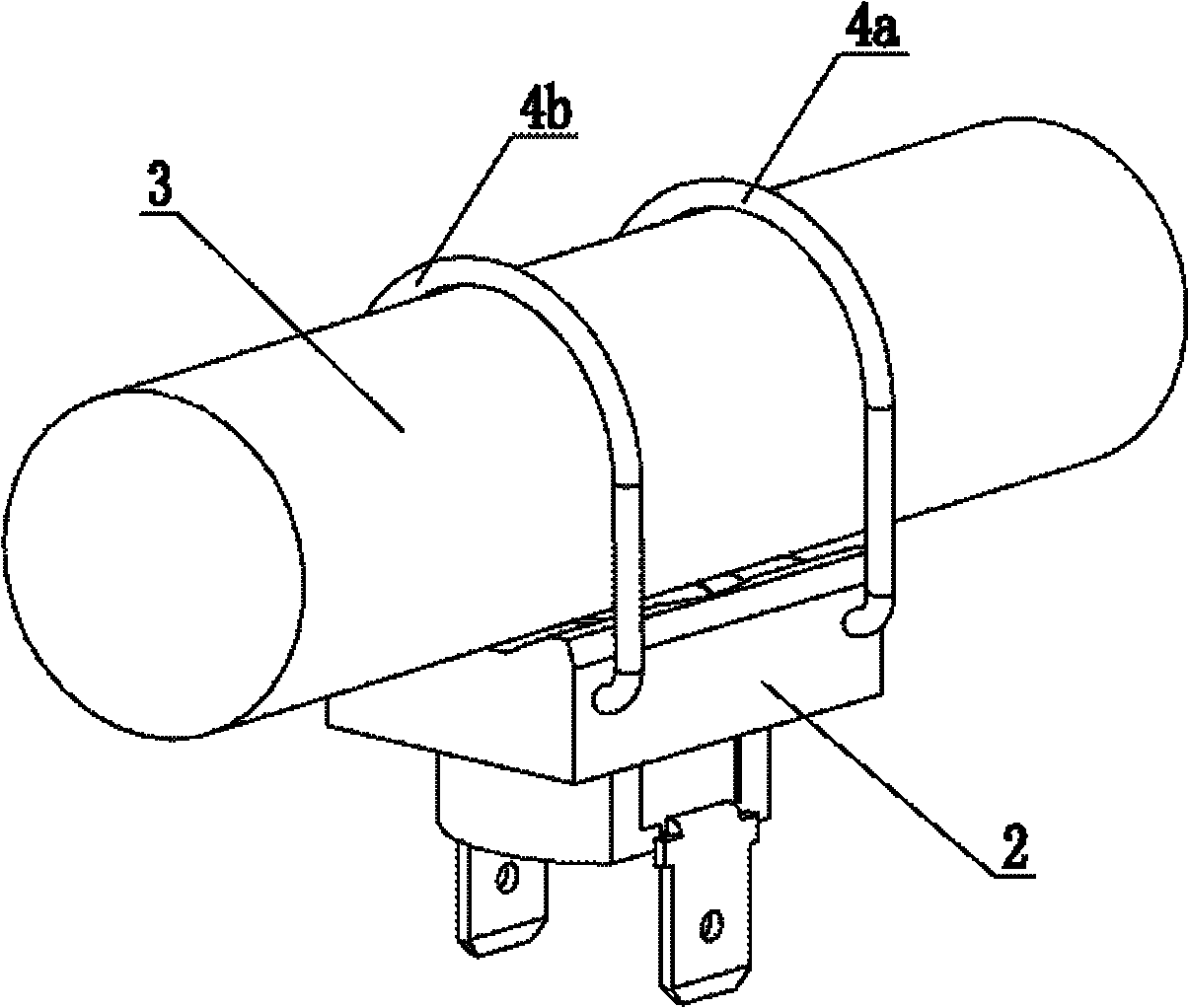

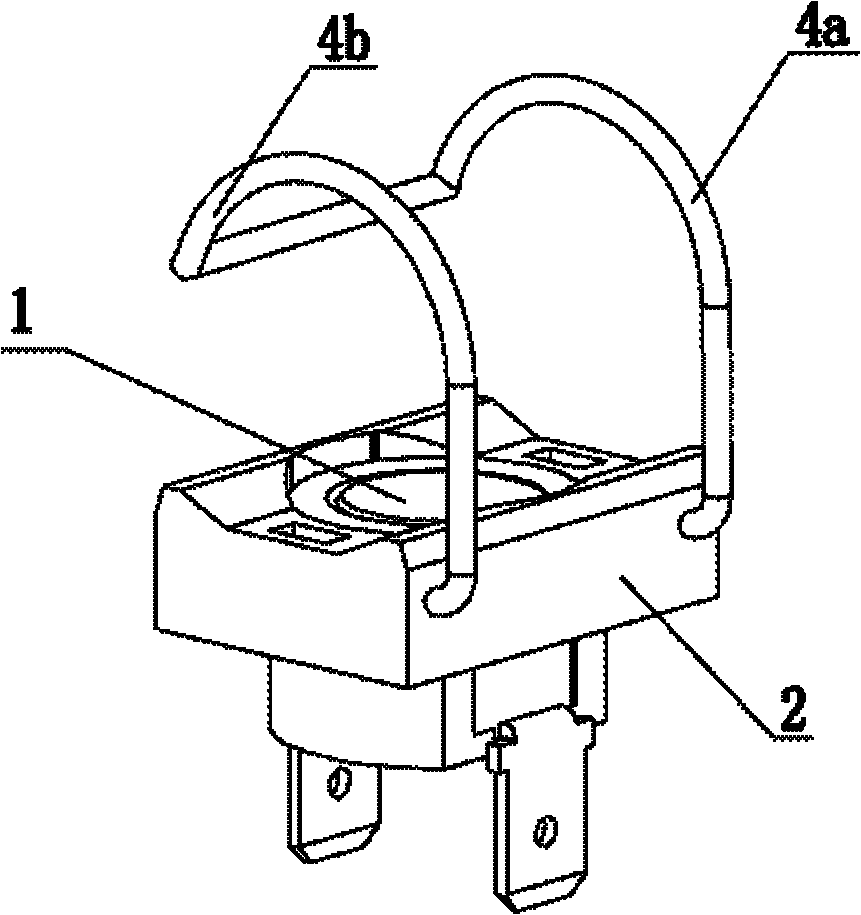

[0010] The tube card thermostat as shown in the figure includes a thermostat 1 and a shell 2 for embedding the thermostat 1. Two parallel steel wire hooks are inserted on the shell wall of the shell 2. 4a, 4b, one end of the two steel wire hooks 4a, 4b is bent and extended into a hook shape along the controlled pipe 3, and the other ends are inserted into the shell walls on both sides of the casing 2 along the lateral direction of the controlled pipe 3. , the radius of the peripheral surface enclosed by the steel wire hooks 4a, 4b and the thermostat 1 is smaller than the radius of the peripheral surface of the controlled pipe 3, and the steel wire hooks 4a, 4b are hooked on the controlled pipe, so that the The thermostat 1 is in close contact with the pipe wall of the controlled pipe parts 4a, 4b.

[0011] Of course, in order to realize the last molding in production, reflect the integrity of the product, and prevent the hooks 4a and 4b inserted on the housing 2 from swinging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com