Hole-drawing machine for saxophone body

A technology for saxophones and card tubes, which is applied in the field of saxophone body hole pulling machines, can solve the problems that the accuracy of the sound hole cannot be guaranteed, the height of the sound hole does not meet the requirements, and the cost of the manufacturer is increased, so as to shorten the processing cycle and ensure the height and expansion, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

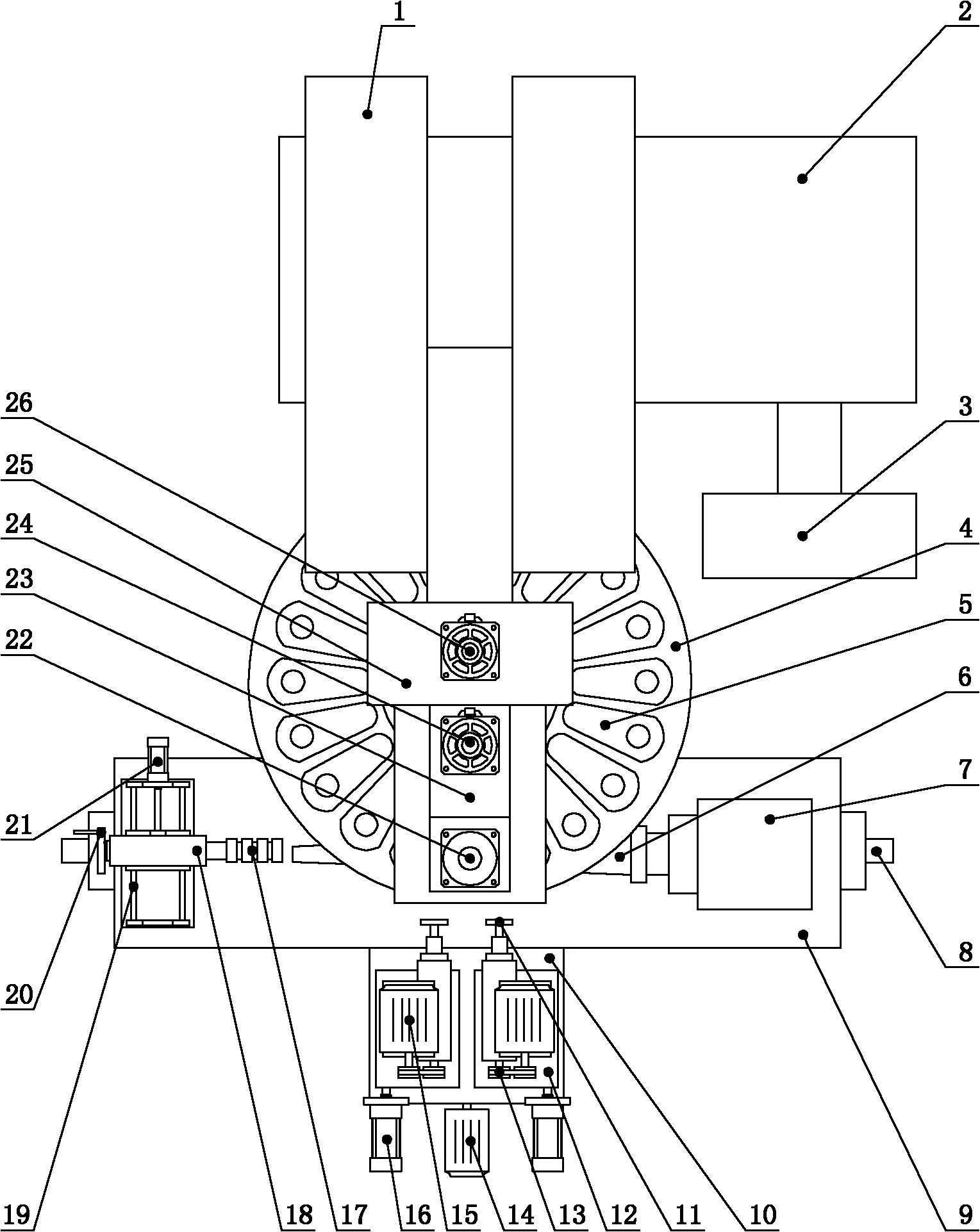

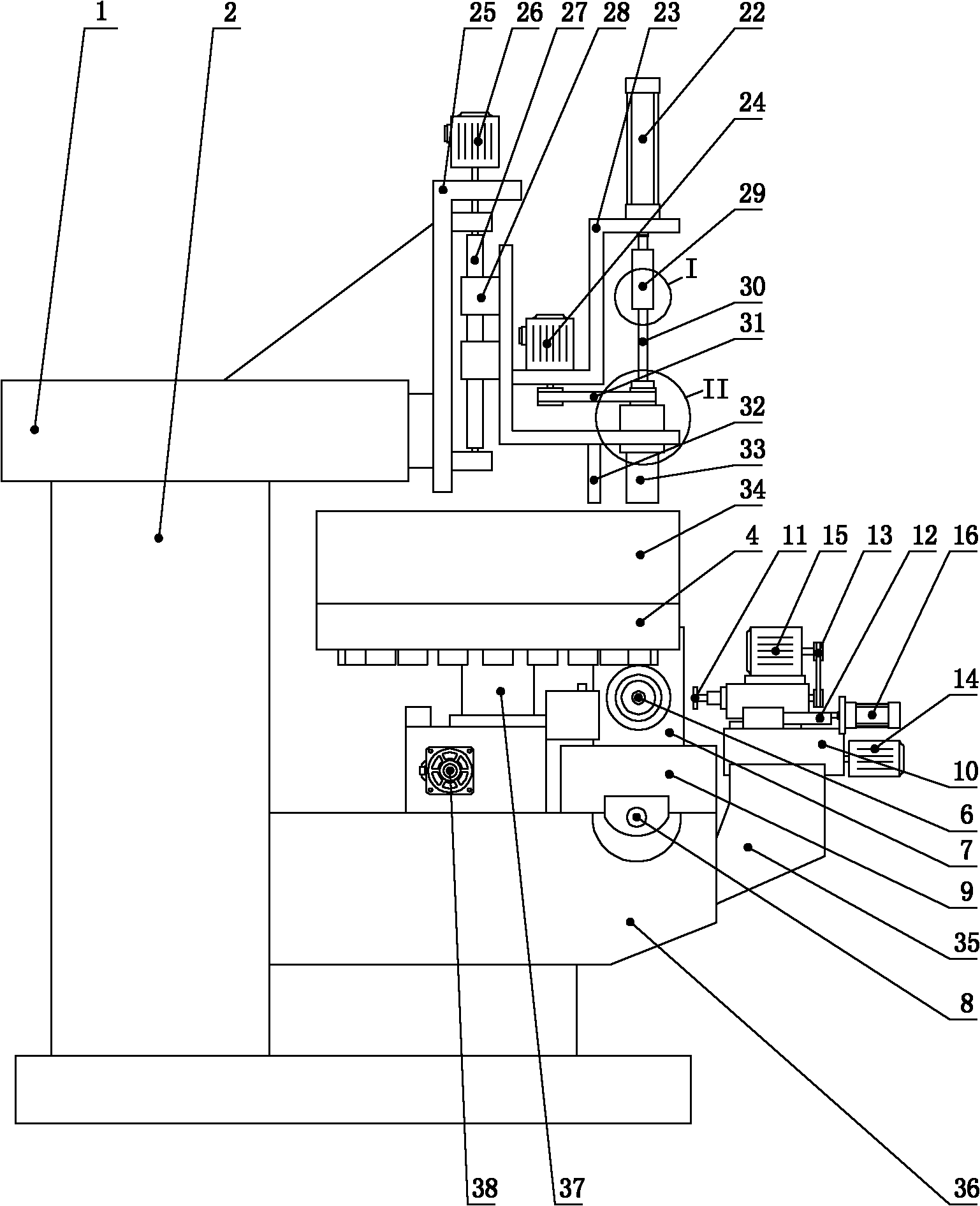

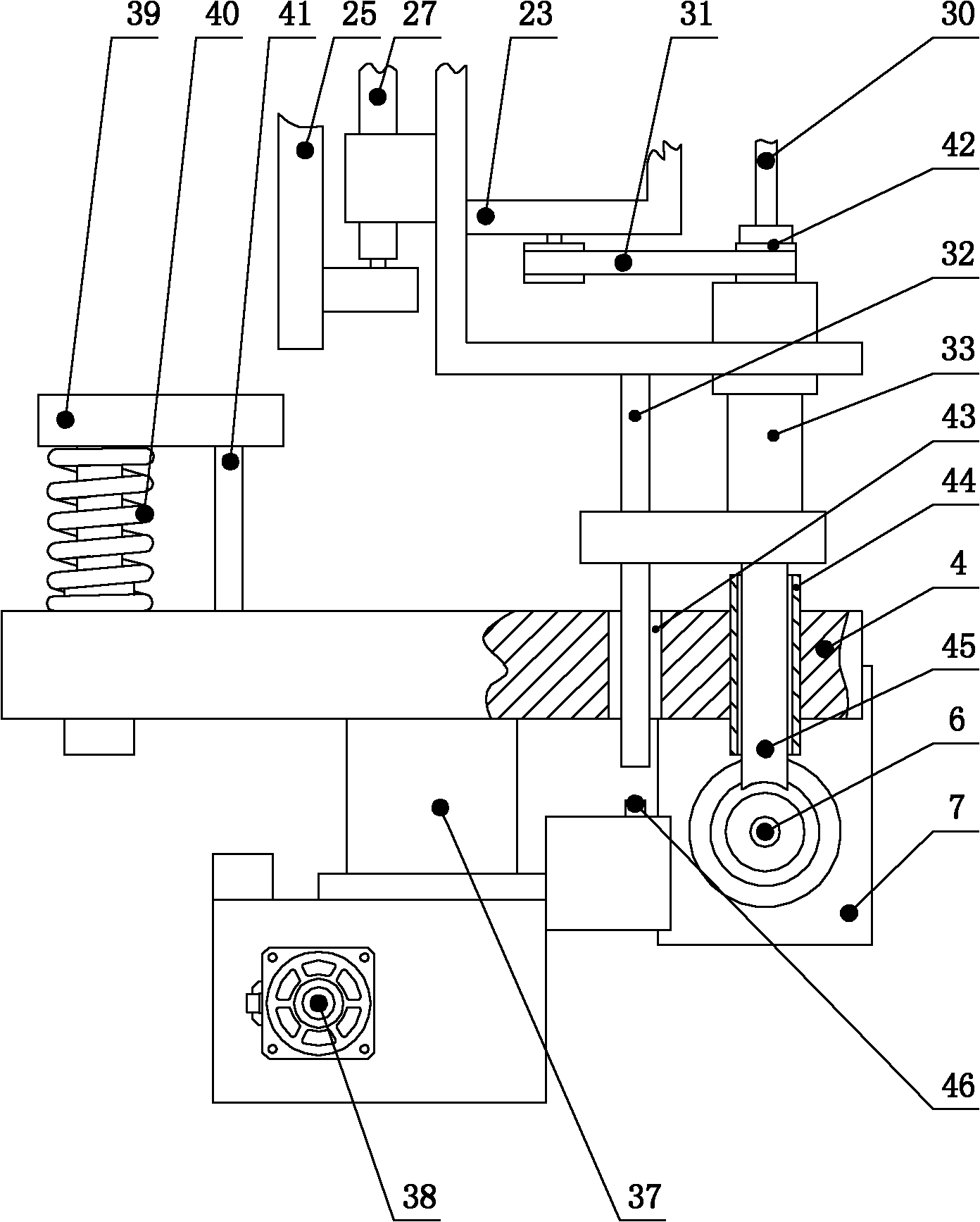

[0024] A saxophone body puller, such as Figure 1-7 As shown, the innovation of the present invention is: comprise base 36, electric control box 2, card pipe rotating mechanism, extruding disc mechanism and extruding pull rod mechanism, electric control box is installed on the rear end of base, and one side of electric control box is installed The man-machine interface box 3 is installed on the base with a squeeze rod mechanism, the middle of the base below the squeeze rod mechanism is installed with a squeeze disc mechanism opposite to the squeeze rod mechanism, and the front end of the base is installed with a card that is opposite to the squeeze disc mechanism. Tube rotation mechanism.

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com