Yellow disperse dye with high light fastness

A technology for disperse dyes and fastness, which is applied in organic dyes, dyeing methods, textiles and papermaking, etc. It can solve the problems of maintaining good color and color fading, improve light fastness, reduce fabric fading, and dyeing Good level dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

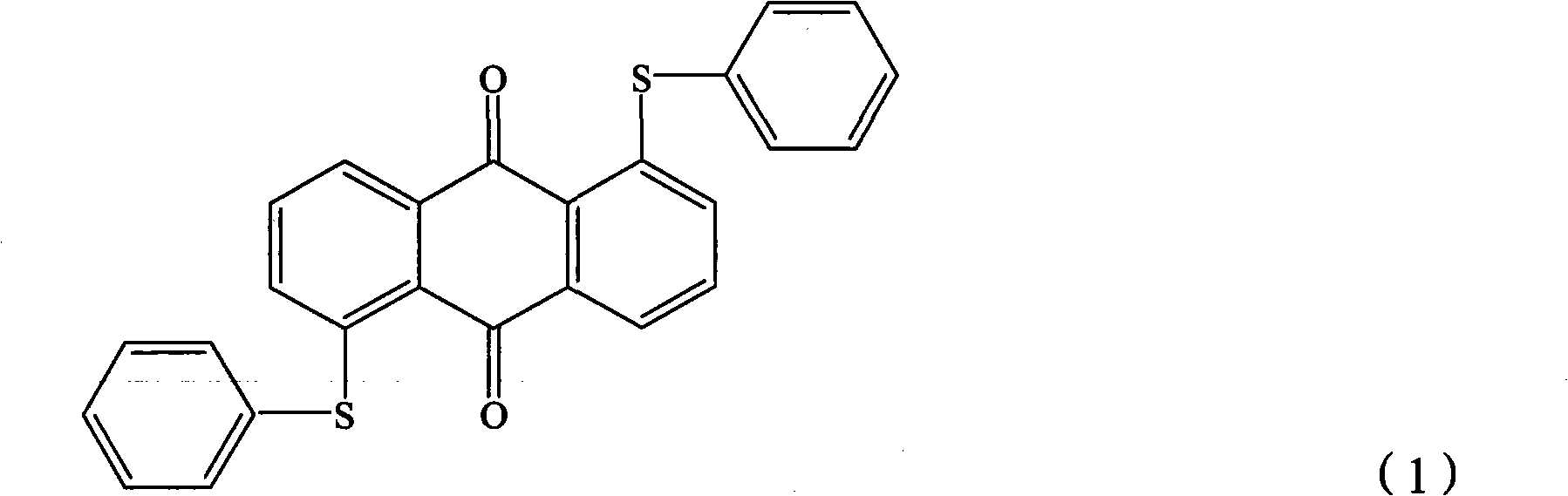

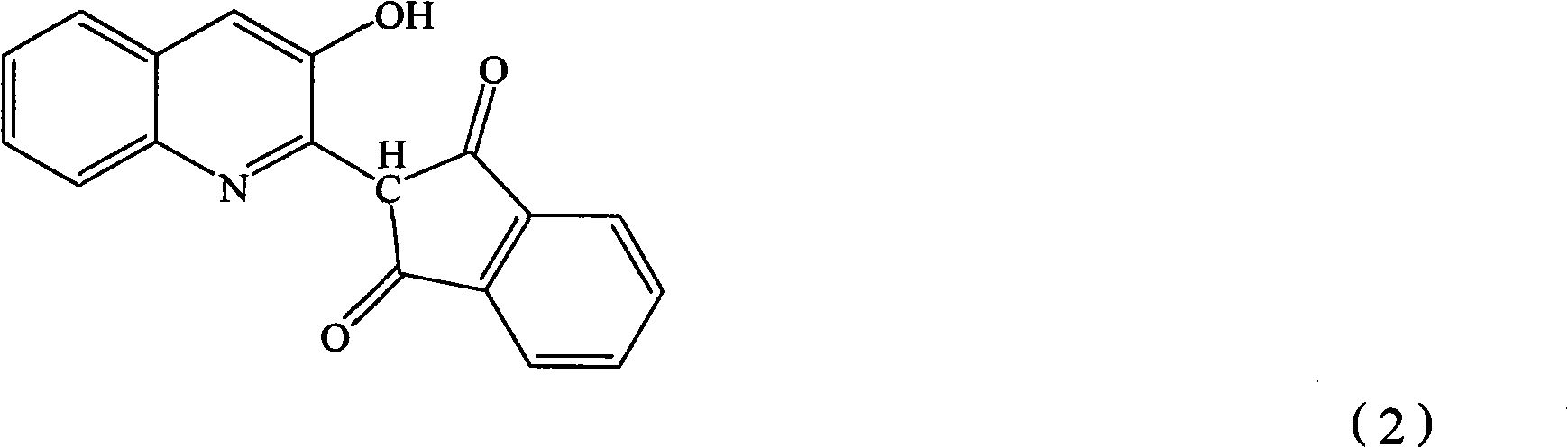

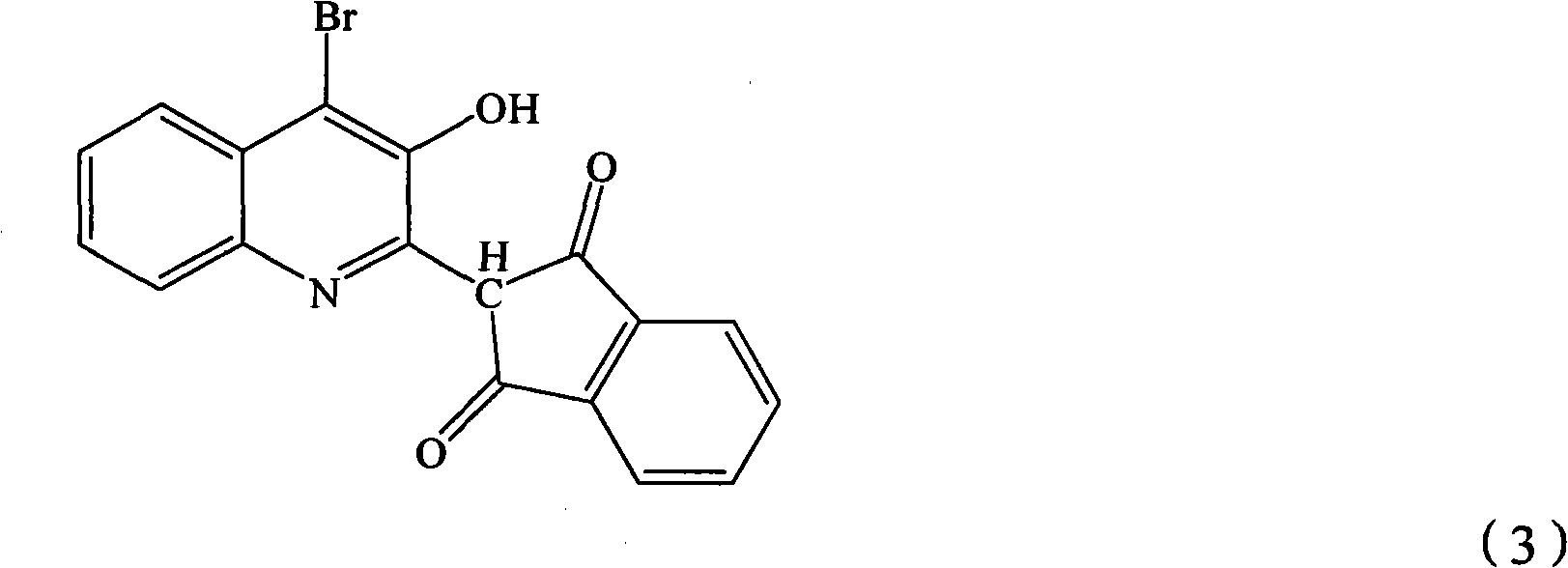

[0022] According to the data shown in Table 1, after pre-dispersing and crushing the original dye monomer A, dye monomer B and dye monomer C in the metering ratio, add a dispersant and warm water to stir, disperse and dissolve, repeat through continuous grinding and filtration, sand After grinding to the end, it is sent to a spray drying tower through a pipeline for drying, and at the same time, dust-proof oil and dispersant are sprayed evenly, and finally the finished product is packaged.

[0023] Table 1

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com