Lignocellulose degrading bacteria and application thereof

A technology of lignocellulose and bacterial strains, applied in the direction of application, fungi, biochemical equipment and methods, etc., to improve the quality of mushroom cultivation substrates and shorten the biotransformation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Embodiment The preparation of mushroom compost microbial inoculant

[0028] Fermentation tank culture solution formula is (percentage by weight): KH 2 PO 4 0.1%, NaCl 0.01%, MgSO 4 ·7H 2 O 0.03%, NaNO 3 0.25%, FeCl 3 0.001%, CaCl 2 0.01%, straw powder 0.5%, pH 7.2-7.4, prepared with water.

[0029] The W4 strain was inoculated on the PDA medium, cultured at 28-30°C for 72h, then inserted into a 500mL Erlenmeyer flask, and cultured statically at 30°C for 48h. Then put it into a 15L seed tank with 1% inoculum size, pH7.2, ventilation rate 0.5vvm, cultivate for 48 hours, then put it into a 100L fermenter with 5% inoculum size, pH7.2, ventilation rate At 0.6vvm, cultivate for 5 days.

[0030] After the fermentation is completed, the strain W4 is added to the sterilized rice bran or wheat bran according to the weight ratio of 2:10-15, sealed in aseptic bags, and stored at room temperature.

experiment example 1

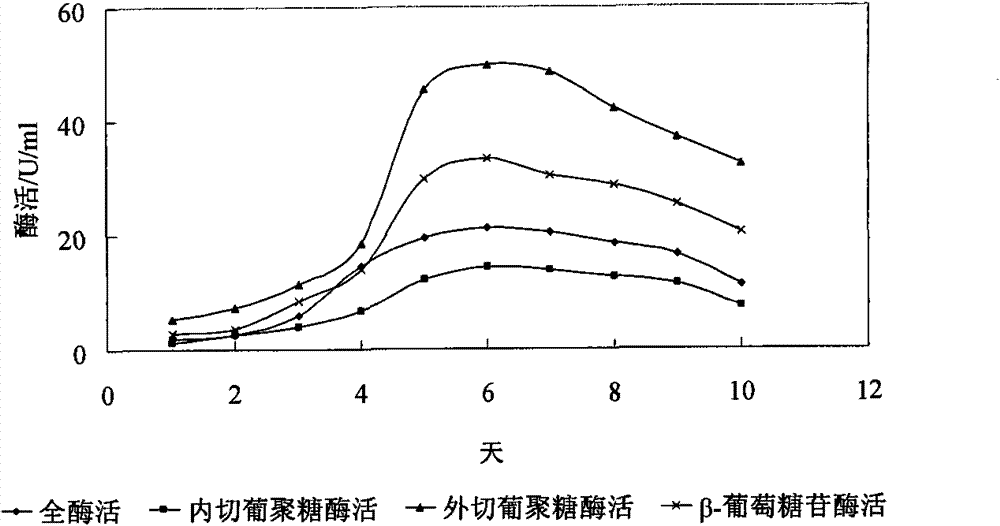

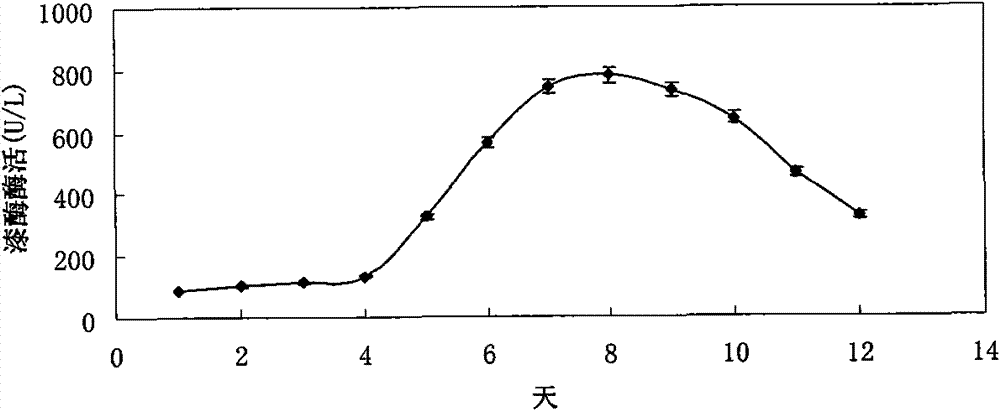

[0031] Experimental Example 1 Enzyme Production Activity Experiment of Bacterial Strain W4

[0032] Liquid fermentation medium (weight percent): KH 2 PO 4 1.0g, NaCl 0.1g, MgSO 4 ·7H 2 O 0.3g, NaNO 3 2.5g, FeCl 3 0.01g, CaCl 2 0.1g, 20g straw powder, pH 7.2-7.4, prepared with water.

[0033] Preparation of cellulose crude enzyme liquid: transfer the spores of the bacterial species cultivated on PDA to normal saline, count with a hemocytometer, press 1% (10 8 spore amount) into 300ml enzyme-producing medium, 28°C, 170rmp liquid fermentation culture, sampling and measuring the enzyme activity of cellulose every 24h, the cultured liquid fermentation enzyme-producing medium was first filtered with two layers of gauze, The filtrate was then centrifuged at 5000 rpm for 10 min at 4° C., and the supernatant was taken as the prepared crude enzyme solution.

[0034] Determination of total enzyme activity: Take 0.5ml of the enzyme solution after appropriate dilution, add it t...

experiment example 2

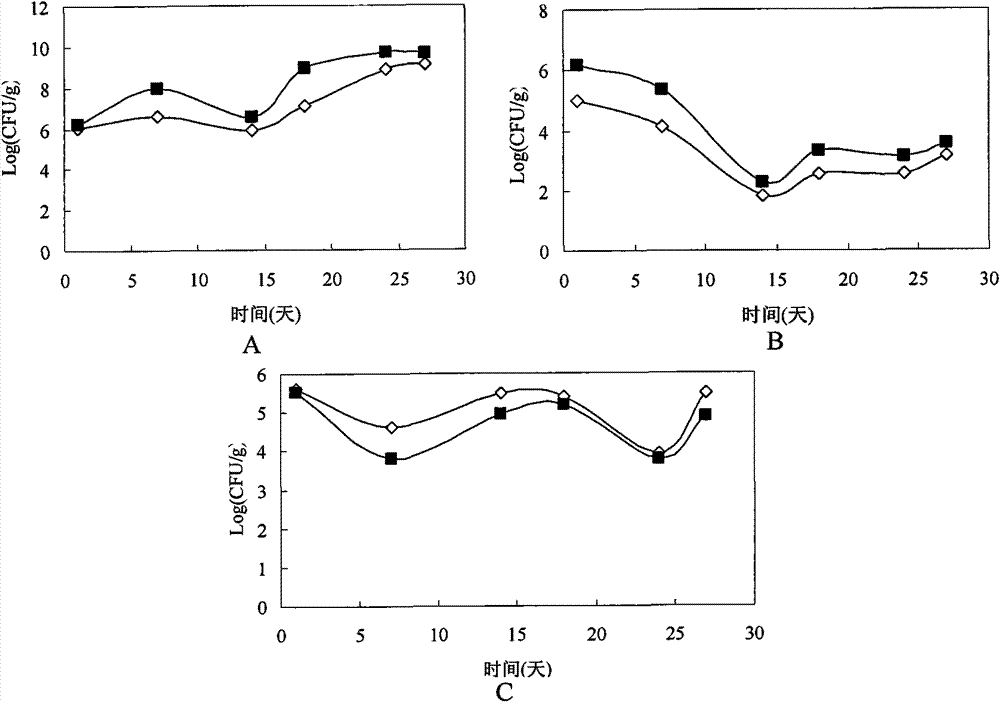

[0042] Experimental example 2 Degradation experiment of strain W4 on straw

[0043] Straw fermentation medium: add 20g straw to 1000ml water, and add nutrient salt KH 2 PO 4 1.0g, NaCl 0.1g, MgSO 4 ·7H 2 O 0.3g, NaNO 3 2.5g, FeCl 3 0.01g, CaCl 2 0.1g, adjust the pH to 7.2-7.4, prepare with water, and sterilize under high pressure at 120°C for 20min.

[0044] Determination of straw weight loss: inoculate strain W4 into liquid seed medium to prepare bacterial liquid, inoculate 1ml of the prepared bacterial liquid into straw fermentation medium, and carry out constant temperature shaking culture. After culturing for 10 days, filter the fermentation liquid with filter paper, and remove the remaining The material was dried at 80°C and weighed, and the weight loss rate of wheat straw was calculated by weight reduction method.

[0045] Determination of straw decomposition rate: The method of Wang Yuwan et al. (1987) was used to determine the content of cellulose, hemicellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com