Lateral movably-connecting combined joint pipe of diaphram wall

An underground diaphragm wall and joint pipe technology, applied in sheet pile walls, underwater structures, water conservancy projects, etc., can solve the requirements of reducing the performance of extubation equipment, reducing the friction between the joint pipe and concrete and soil, etc. , to avoid the hidden danger of water leakage, to facilitate field operations, and to achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

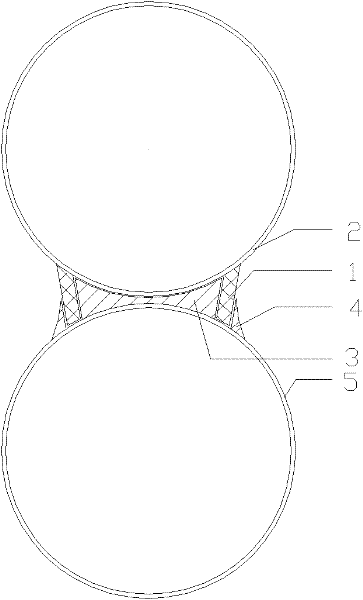

[0024] Below in conjunction with accompanying drawing, the structure of underground diaphragm wall horizontal live connection combined joint pipe of the present invention is further described:

[0025] The design idea of the combined joint pipe for horizontal movable connection of the underground diaphragm wall of the present invention is to allow two independent joint pipes to work together as a whole through buckle connection. Quantity, the live connection is characterized in that it can move separately during use, it is combined and connected together, and it is not restricted by the connection, forming an independent joint pipe for lifting operations. Thereby, the pull-out force of the joint pipe is reduced, and the risk of pulling out the joint pipe is reduced.

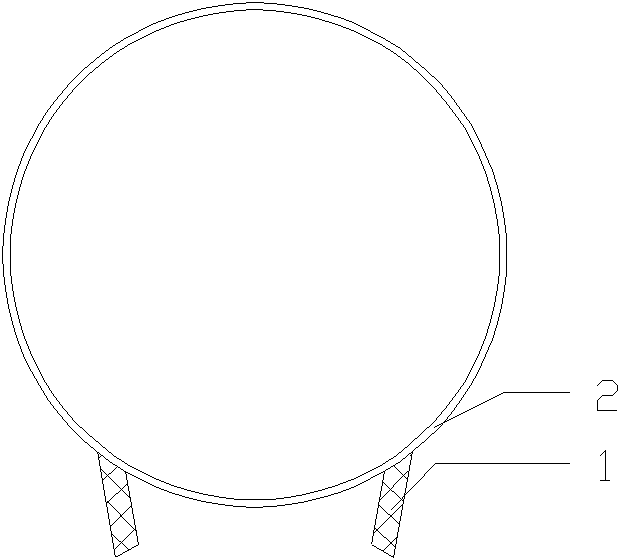

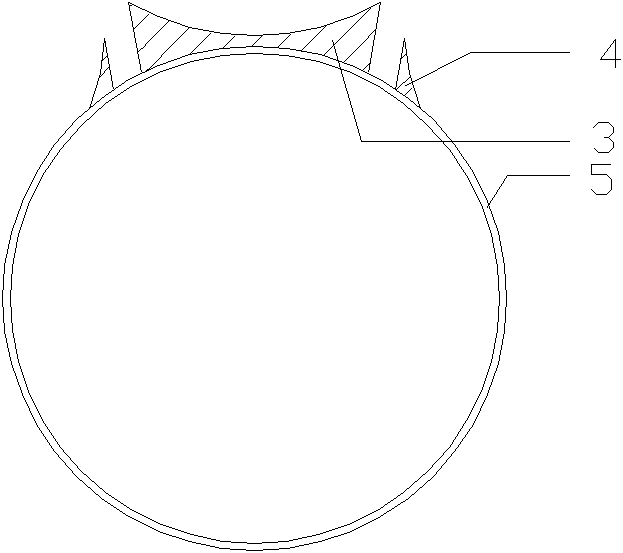

[0026] The combined joint pipe for transverse living connection of the underground diaphragm wall of the present invention has two independent first joint pipes 2 and second joint pipes 5, and the first joint p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com