Single punch tablet press

A technology of pressing tablets and punching through holes, which is applied in the direction of punching machines, presses, and material forming presses, etc., can solve the problems of complex transmission system, poor system controllability and flexibility, energy consumption, etc., and achieve simple transmission system Direct, controllable and flexible, reduce vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

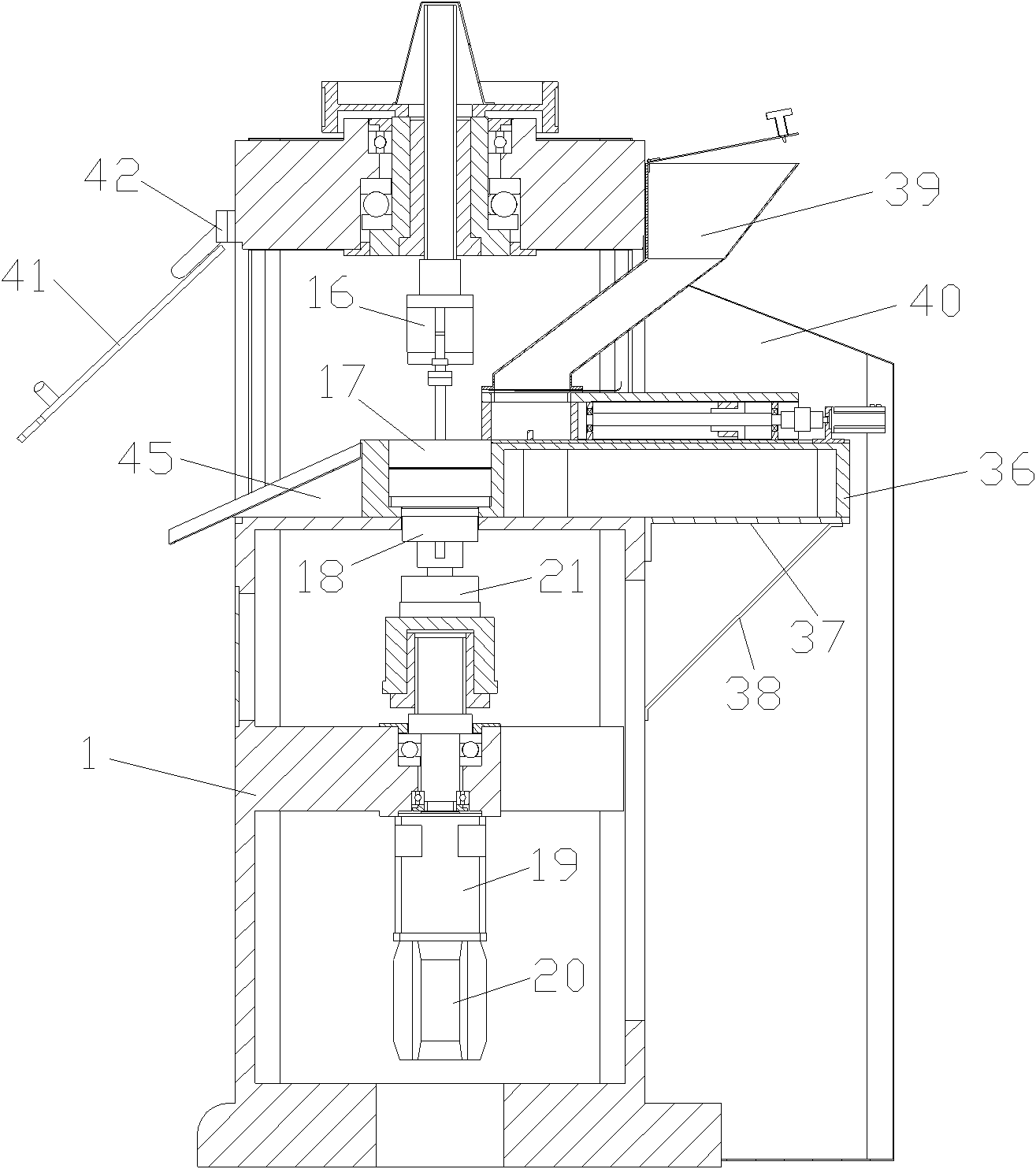

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

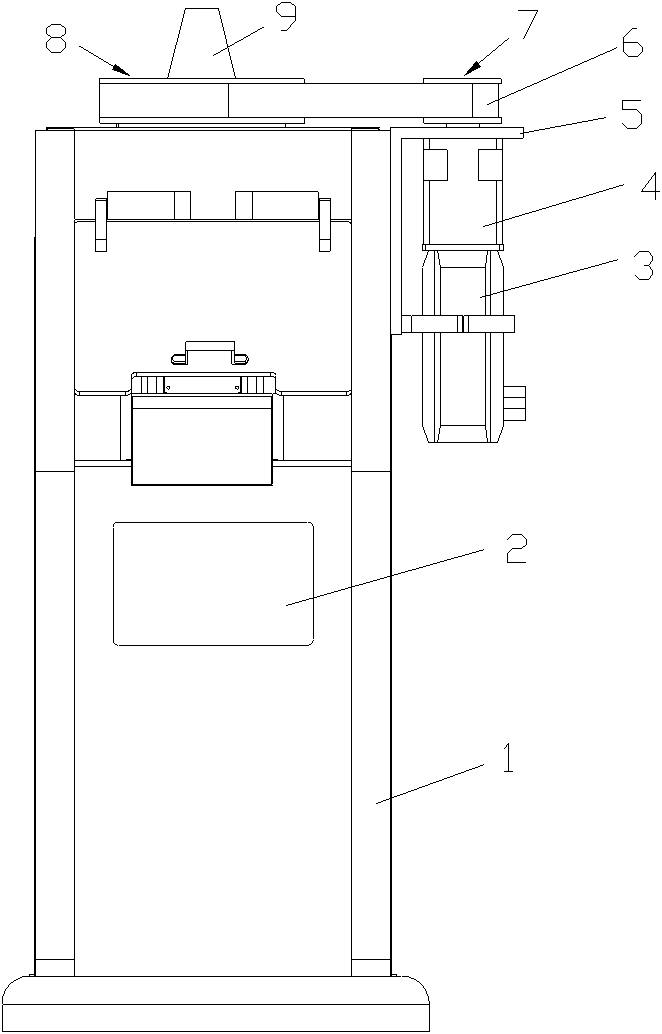

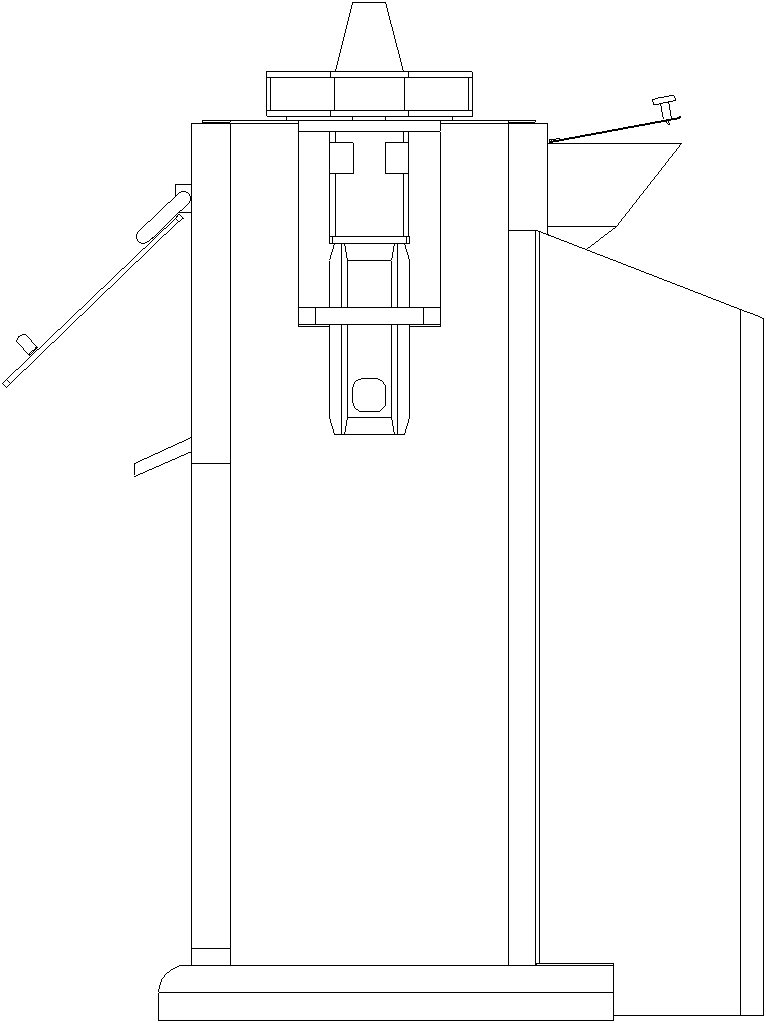

[0029] see figure 1 , figure 2 or image 3 , the single-punch tablet press of the present invention includes a frame 1 and a tablet pressing mechanism arranged on the frame 1, and also includes some covers for closing the whole machine and a working window 2, a support frame 37, and an inclined support frame 38 , Hinged leaf 42. Wherein the tablet pressing mechanism is made up of middle mold 17, main pressure mechanism, feeding mechanism and top sheet mechanism. The main pressure mechanism is composed of upper punch 16 and upper punch transmission mechanism; the feeding mechanism is composed of material box 35 and material box transmission mechanism. Top film mechanism is made up of punching 18 and punching transmission mechanism under punching. The middle mold 17 is provided with a vertical punching through hole, and the cross section of the punching through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com