Reinforced concrete building structures and methods thereof

A technology of reinforced concrete and concrete, which is applied in the direction of building components, building structures, buildings, etc., and can solve the problems of not being able to obtain rigid continuous floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. The same reference numerals are used in the drawings and embodiments to refer to the same or similar parts, as appropriate.

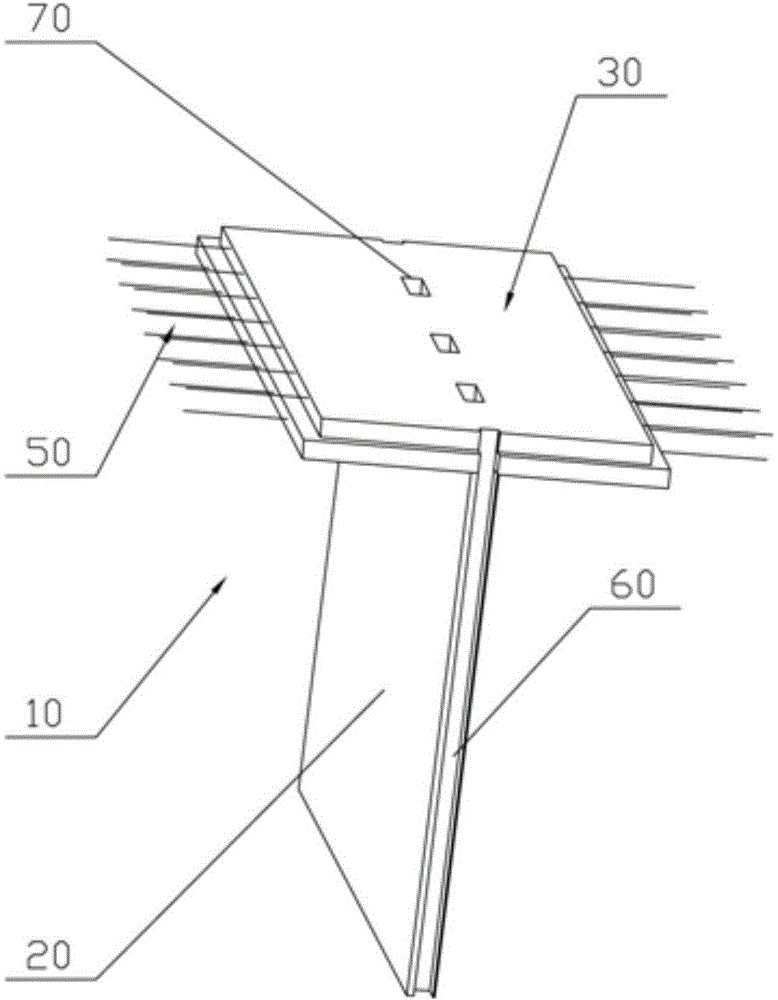

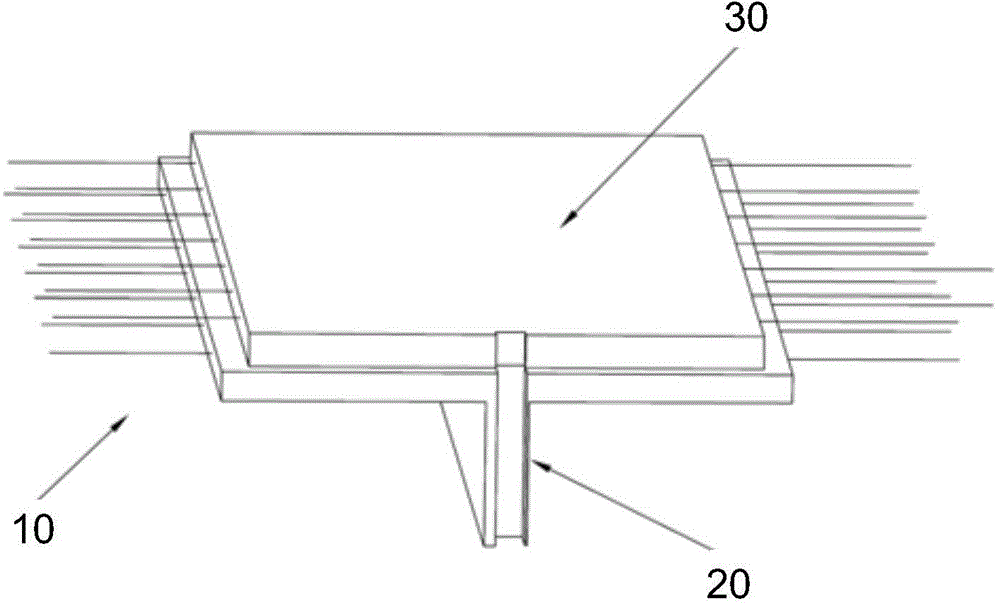

[0050] figure 1 A set of four supports 1 is illustrated having a column 2 with a precast concrete slab 3 fixed horizontally thereto. The plate 3 is stepped down to half its thickness at the four edges, forming a stepped edge 4 with a height of, for example, 10 cm, on which a pre-cast floor or an in-situ manufactured floor can be deposited. The stepped edge 4 is reinforced by steel bars 5 which run through the plate 3 horizontally and in parallel and protrude a predetermined distance on all four faces vertically paired close to the top and bottom faces of the pre-cast plate 3 (for example, half a meter). The hollow cylinder 2 is centrally located under the precast plate 3 and is fixed by a flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com