Wheel guide rail, car wash system and method for centrally positioning a vehicle

A technology for guiding rails and vehicle cleaning, which is applied in the direction of vehicle cleaning equipment, vehicle cleaning, vehicle maintenance, etc., and can solve problems such as electric shock, vehicle damage and damage to the conversion arm, and achieve the effect of avoiding damage and large measurement windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

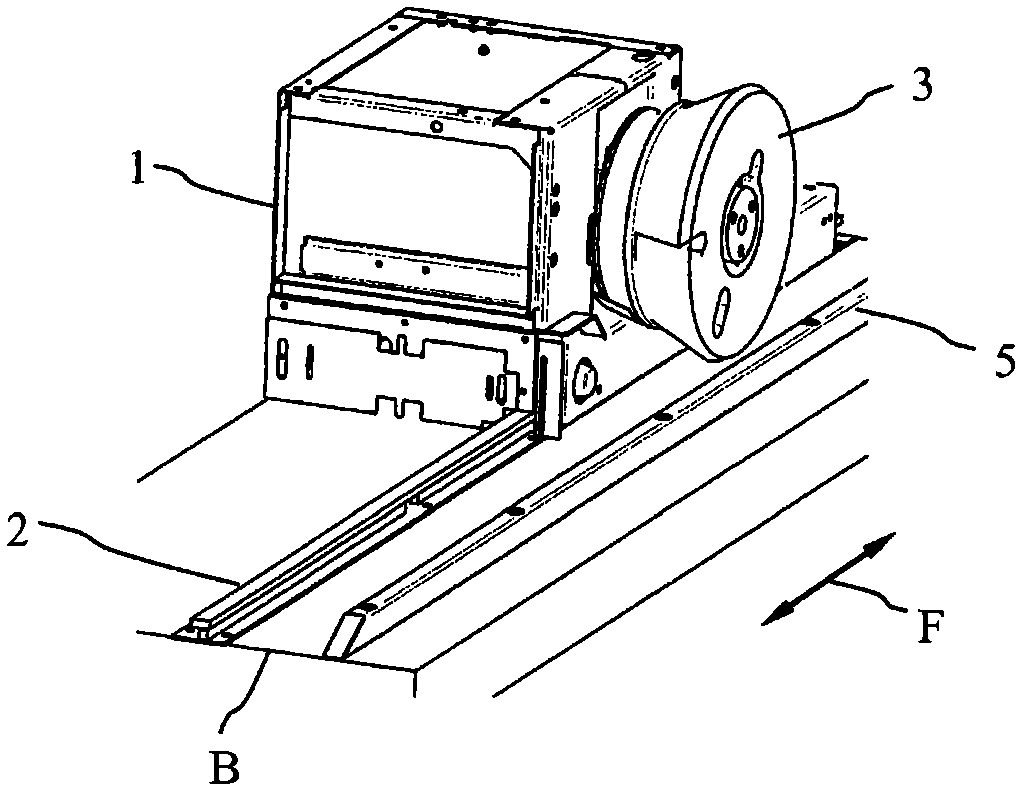

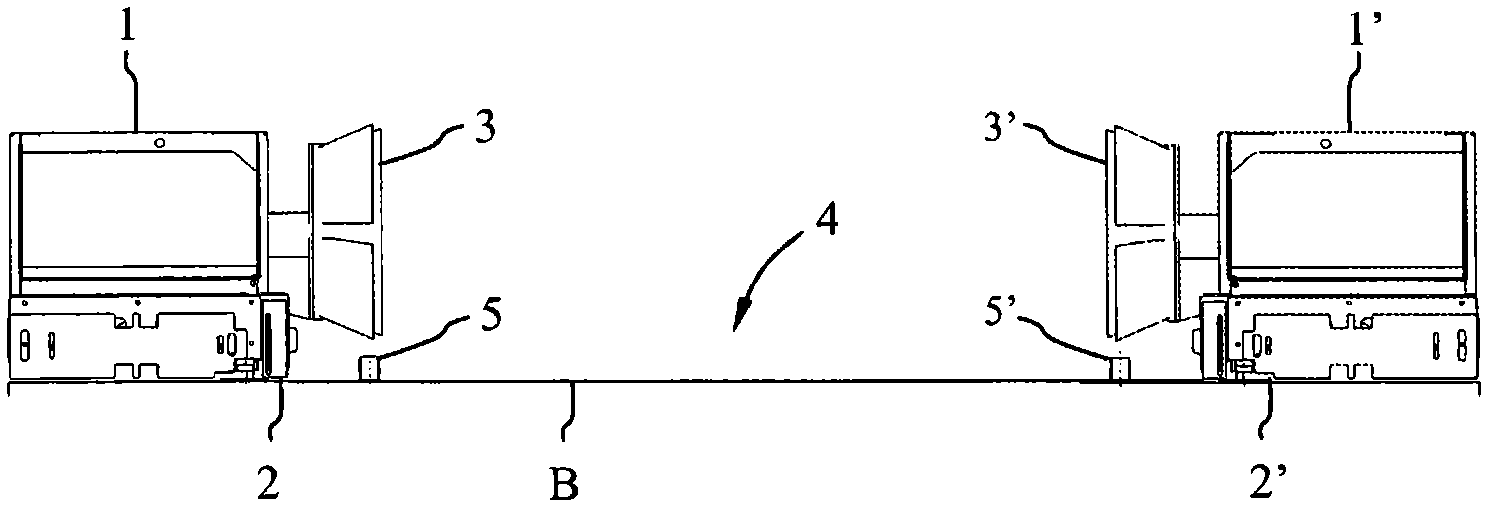

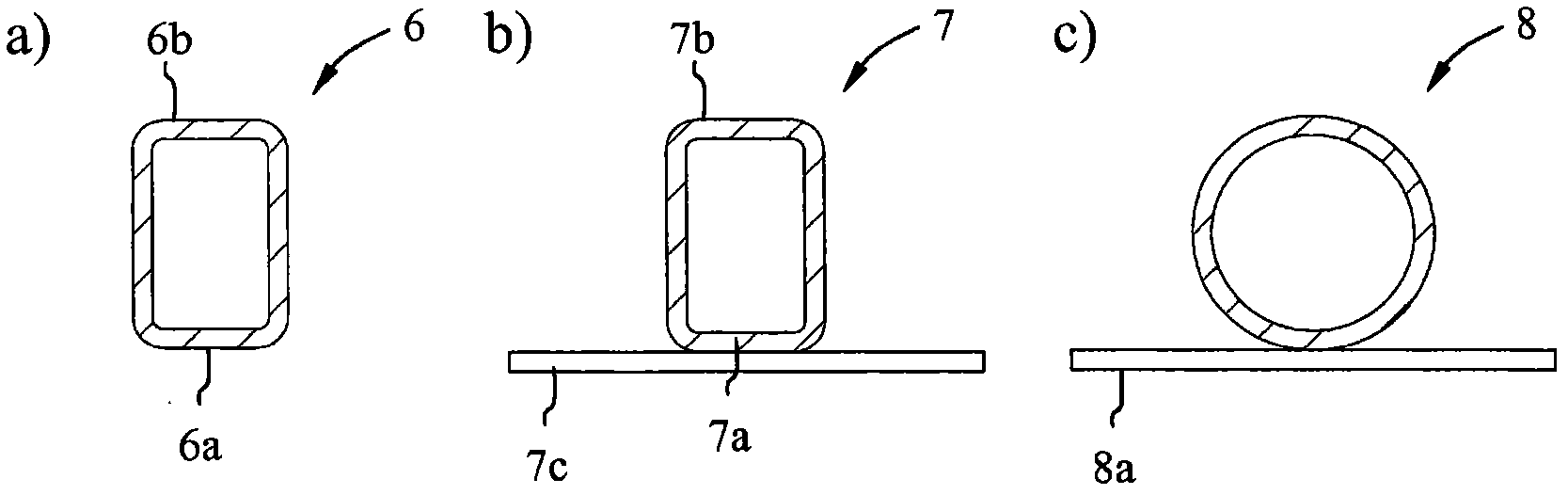

[0034] Figure 6 to Figure 9 A cross-section of the wheel guide rail according to the invention is shown in the installed state. Wheel guide rails have longitudinal dimensions that match vehicle washing equipment, such as Figure 4 shown in the example. The wheel guide rails according to the invention have fastening means, not shown in the drawings, for example holes in their bottom region, by means of which fastening means these wheel guide rails can be screwed to the bottom of the cleaning device. The direction of movement F of the vehicle to be cleaned in the vehicle washing facility is perpendicular to Figure 6 to Figure 9 the drawing plane.

[0035] The wheel guide track 9 is in the Image 6 The embodiment according to the invention shown in includes an elongated hollow profile made of a stable material, here steel. The bottom 9a and the end side 9b are coplanar and substantially parallel to the bottom B of the washing device.

[0036] The wheel guide side wall 9c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com