Control method for improving economical operation of boiler charge returning air blower

A control method and technology of economical operation, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of high operation risk, affecting the return effect of the returner, and coking in the furnace, and achieve the effect of optimizing the control logic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in conjunction with the following examples.

[0014] An embodiment of the control method for improving the economical operation of the boiler return fan of the present invention, the steps include:

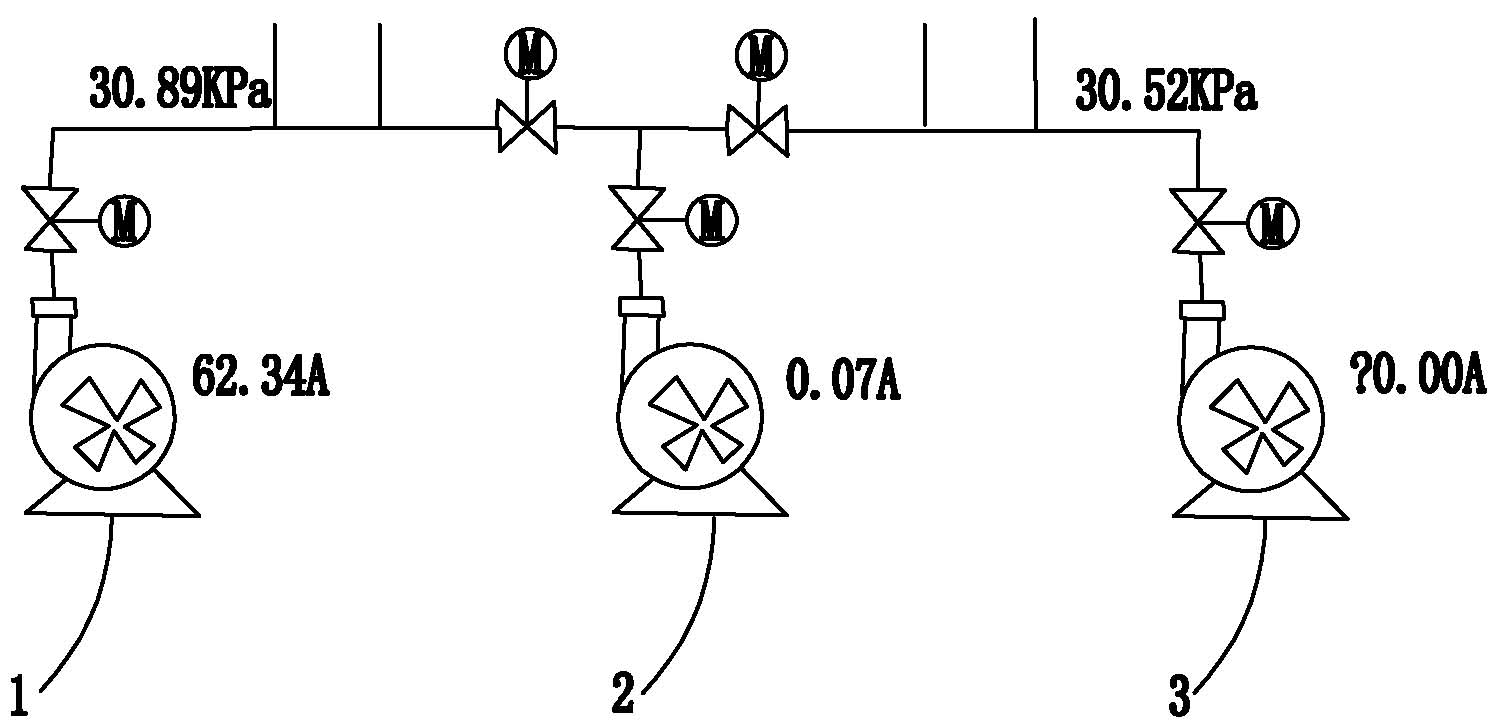

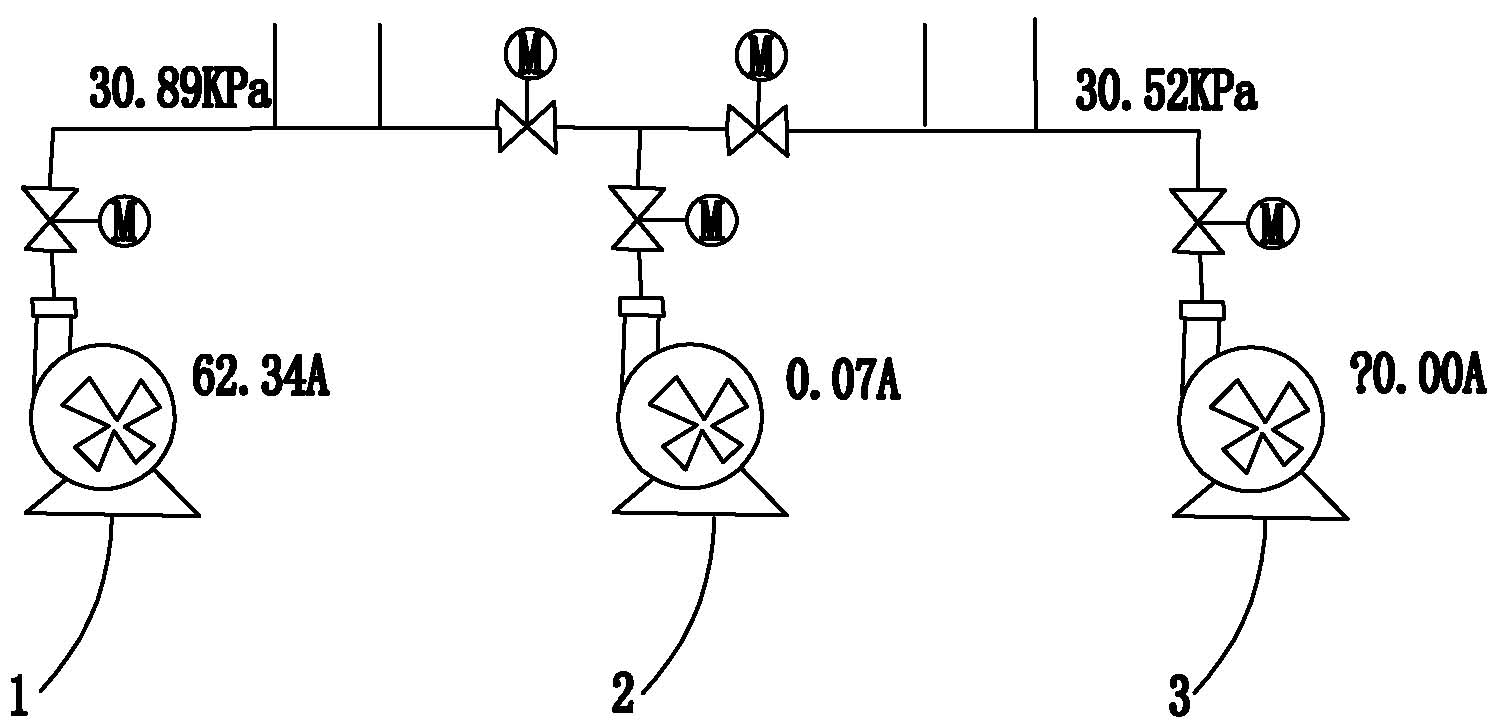

[0015] A. Configure three return fans, namely No. 1 return fan 1, No. 2 return fan 2 and No. 3 return fan 3. When the boiler is in normal operation, No. 1 return fan 1 and No. 2 return fan 2 are operated. And No. 3 return fan 3 standby;

[0016] B. Preset the outlet air pressure setting value at the outlet of each return fan of the boiler;

[0017] C. A pressure sensor is set at the outlet of each return fan of the boiler, and the outlet air pressure average value of each return fan measured by the pressure sensor is calculated, and the outlet air pressure average value and the outlet air pressure setting value for comparison;

[0018] D. If the average value of the outlet air pressure is less than the set value of outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com