Full-lining bidirectional composite soft sealing butterfly valve

A soft sealing and lining technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of large-caliber butterfly valve switching torque is too large, can not meet the requirements of two-way sealing, and the valve plate is easy to lock and close when it is closed. Improve corrosion resistance, good compensation and limit, not easy to lock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

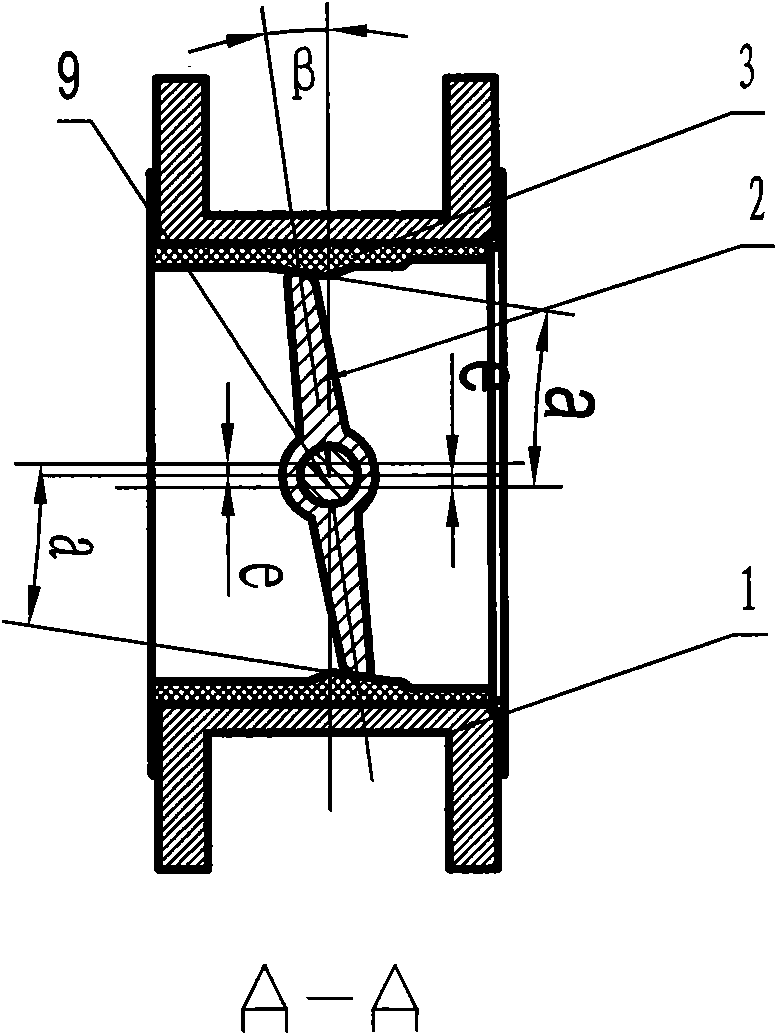

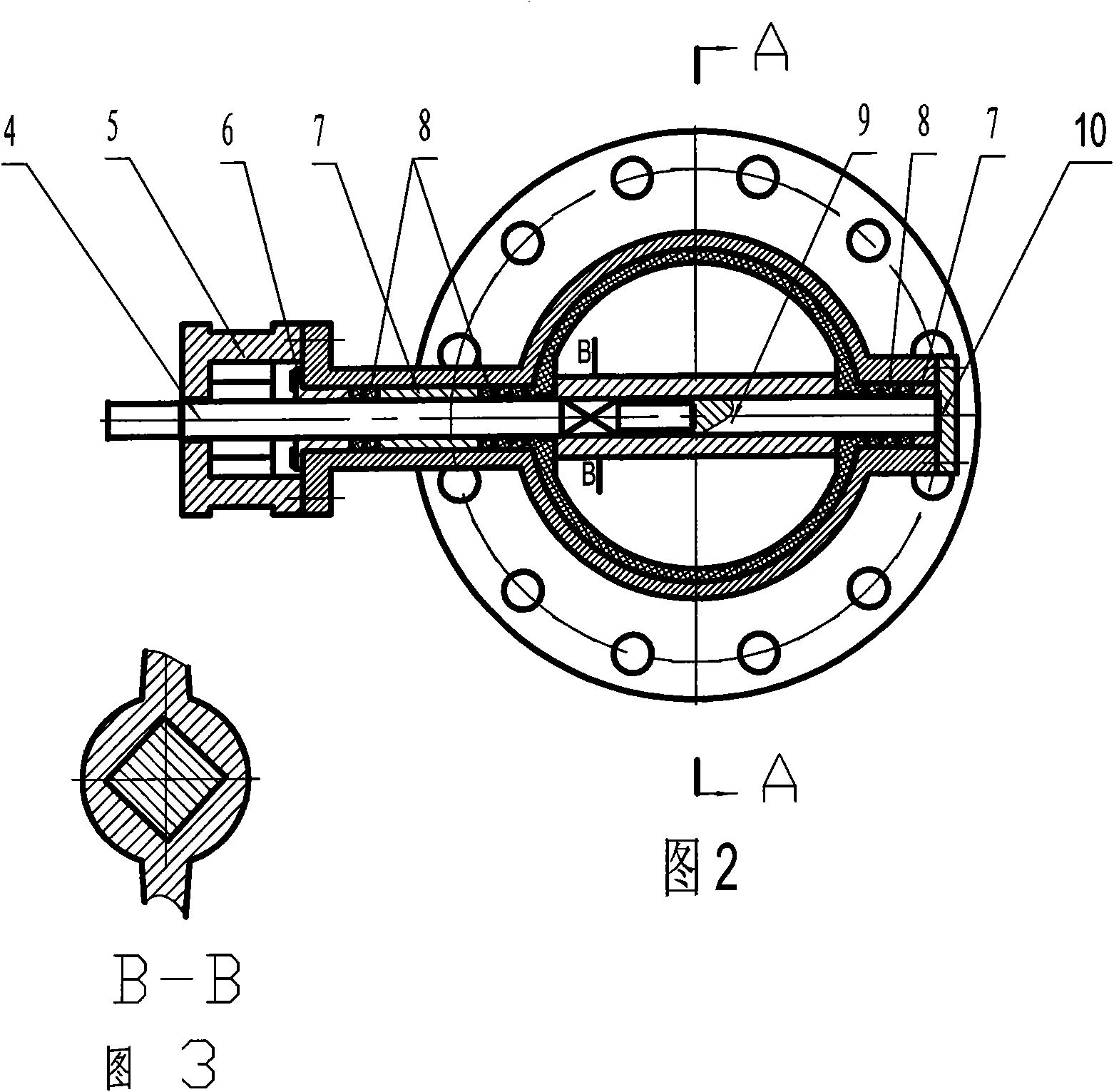

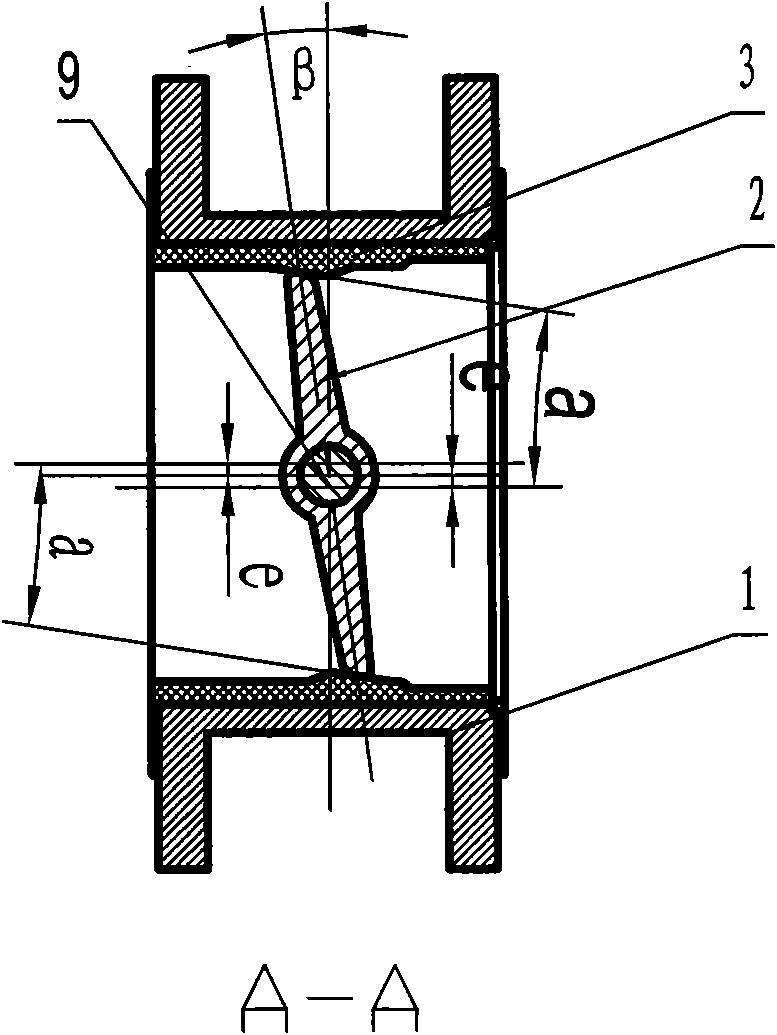

[0020] Attached below Figure 1-3 The present invention is described further:

[0021] Refer to attached Figure 1-3 :

[0022] The fully lined two-way composite soft seal butterfly valve consists of a valve body 1, a valve plate 2, a valve seat 3, an upper valve shaft 4, a seat 5, a packing gland 6, a bushing 7, an O-ring 8, and a lower valve shaft 9 And the rear end cover 10 is formed. The valve seat 3 is directly vulcanized on the valve body 1 in the form of a composite eccentric inclined plane seal and completely covers the valve body 1, and extends to both sides of the valve body 1, such as figure 1 As shown, the valve seat 3 forms an included angle α with the upper semicircle of the valve plate 2 and is offset by a distance e relative to the axis (also the center of the valve body). The center of the valve body) is offset by a distance e, and the two eccentrics overlap at the center of the valve body to form a compound eccentric slope sealing form of the valve seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com