Electric furnace charging process for high-titanium blast furnace slag carbonization

A technology of blast furnace slag and high titanium type, which is applied in the field of comprehensive utilization of high titanium type blast furnace slag, can solve the problems of difficult implementation of liquid slag hot charging into a furnace, difficult maintenance of complex auxiliary facilities, and difficult to estimate costs, and achieves good protection. Action, easy implementation, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] An engineering test was carried out in a factory, including the following steps:

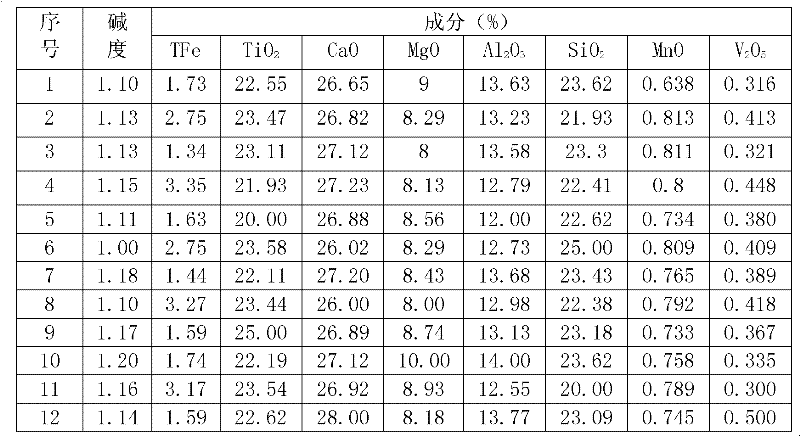

[0034] 1) Control the blast furnace slag discharge temperature above 1450°C, the basicity is 1.00-1.20, and the composition of blast furnace slag includes SiO by weight percentage 2 20-25%, Al 2 o 3 12~14%, CaO 26~28%, MgO 8~10%, TiO 2 20~25%, V 2 o 5 0.3-0.5%, the specific composition of the slag is shown in Table 1;

[0035] Table 1. Composition list of blast furnace slag

[0036]

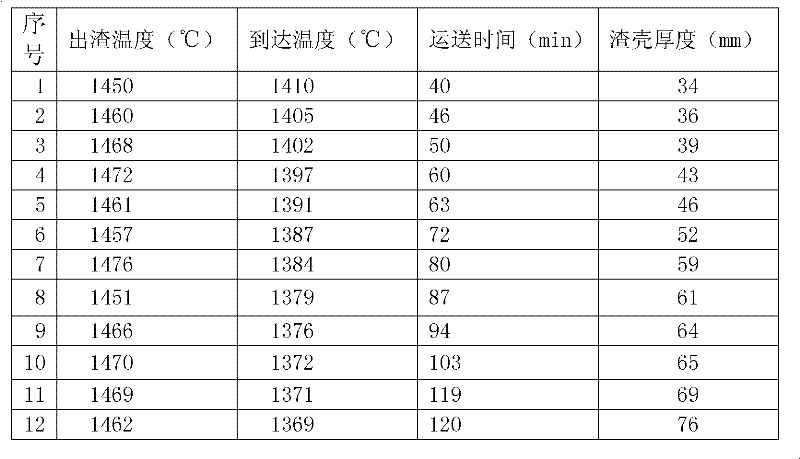

[0037] 2) The liquid blast furnace slag is introduced into the slag tank car through the slag ditch, and the opening of the slag ditch is closed by a cover lined with refractory material. The slag tank car adopts an ordinary ZG30V cast steel slag tank car, and the length, width and height dimensions are 4300×3380× 2980mm;

[0038] After the slag tank car is connected to the slag, the basic oxide slag-forming material MgO is evenly spread on the surface of the blast furnace slag in the slag tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com