Automatic punching machine for pagodite of lighter

A technology of punching machine and lighter, which is applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc., can solve the problems of high scrap rate, low production efficiency and poor drilling quality. , to achieve the effect of low scrap rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Please refer to the accompanying drawings to illustrate its implementation process:

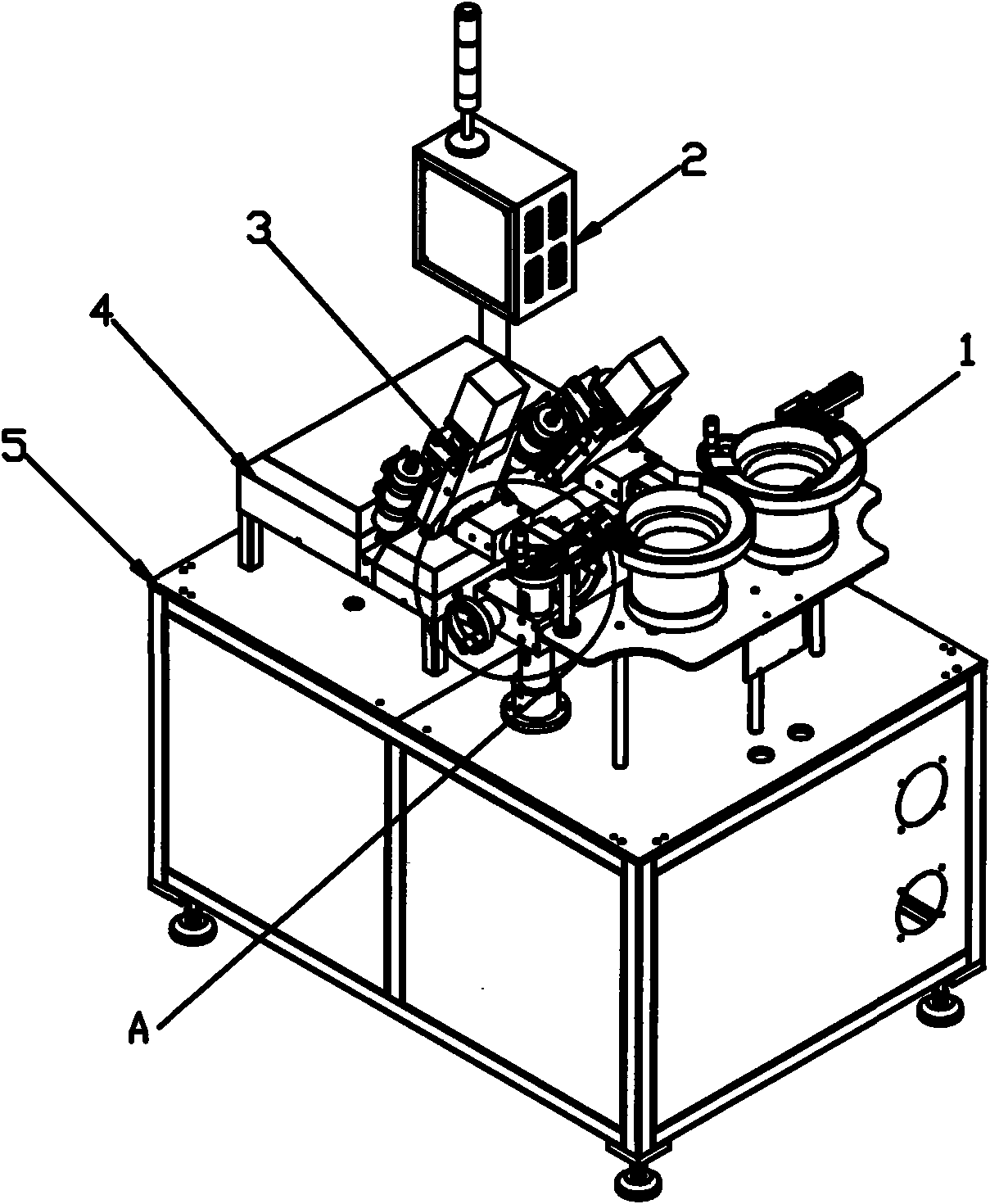

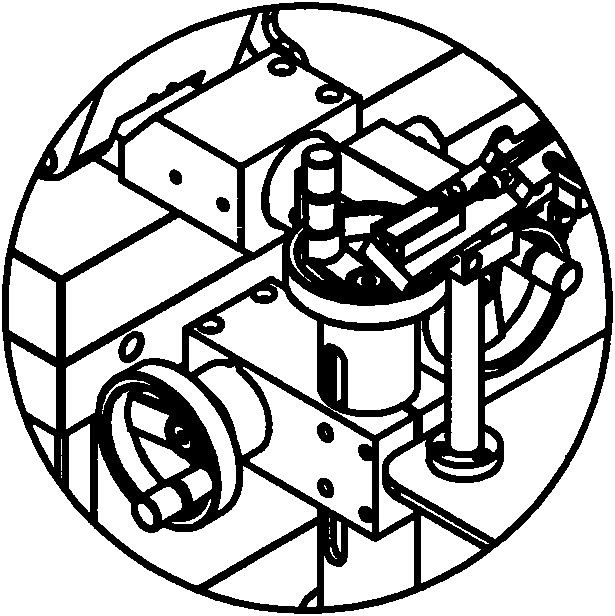

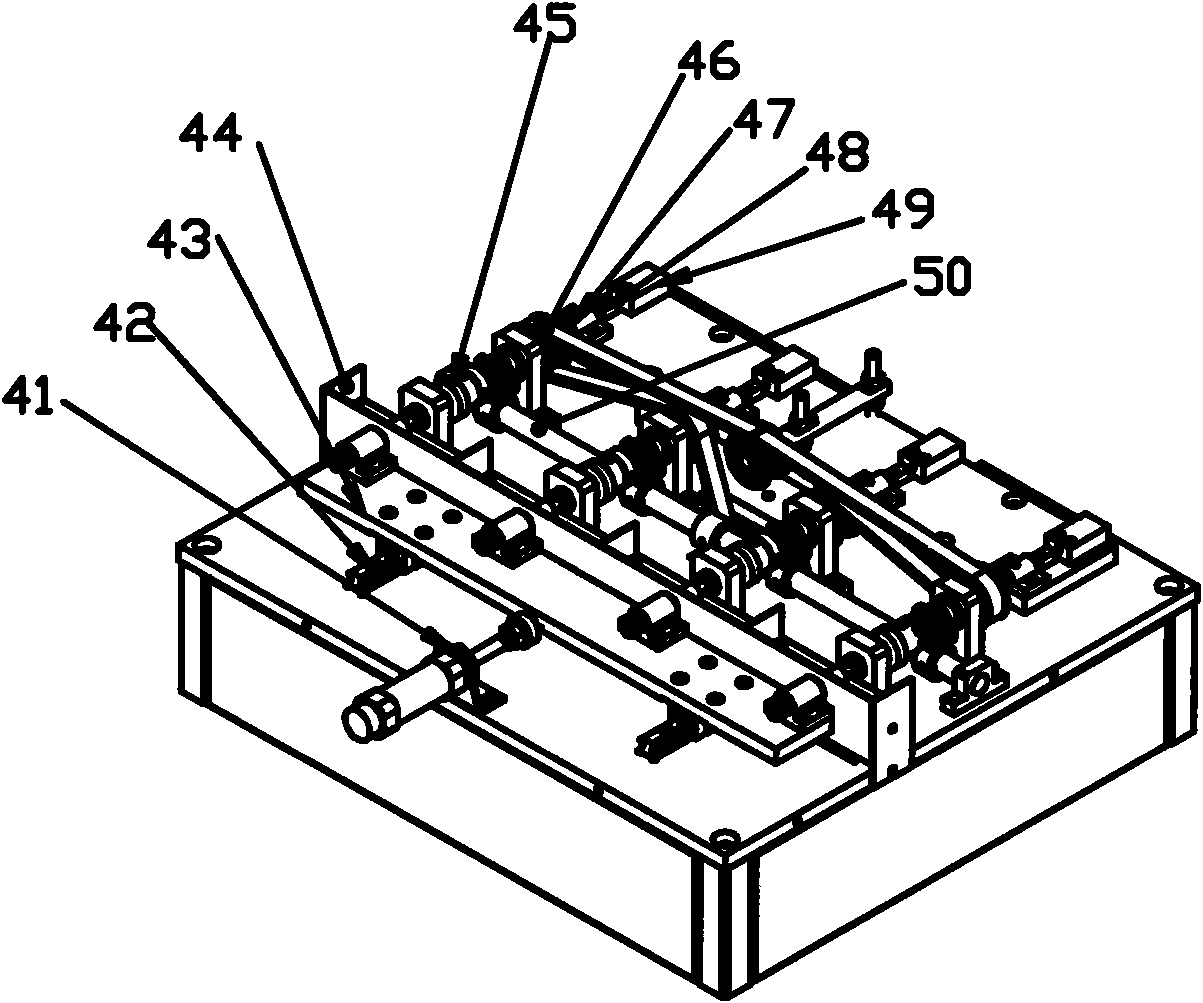

[0016] The lighter pagoda automatic punching machine includes a frame 5. The automatic punching machine is composed of a feeding device 1, a control circuit 2, a punching mechanism 3 and a clamping and indexing blanking device 4. The feeding device 1 and the punching mechanism 3 are connected through the transmission parts for material delivery, and the control circuit 2 is electrically connected to the feeding device 1, the punching mechanism 3 and the clamping indexing and unloading device 4 respectively. The structure of the punching mechanism 3 is as follows: the front end of the electric spindle 31 is provided with a drill bit 30, the electric spindle 31 is installed on the electric spindle mounting frame 33, an adjustment mechanism is installed beside the electric spindle mounting frame 33, and the electric spindle 31 is connected by a ball screw 33. On the vertical servo motor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com