Locking device for a battery block of ground transportation vehicle

A technology of transportation tools and locking devices, which is applied in the field of locking devices of battery blocks, can solve problems such as roller contact surface sinking, and achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

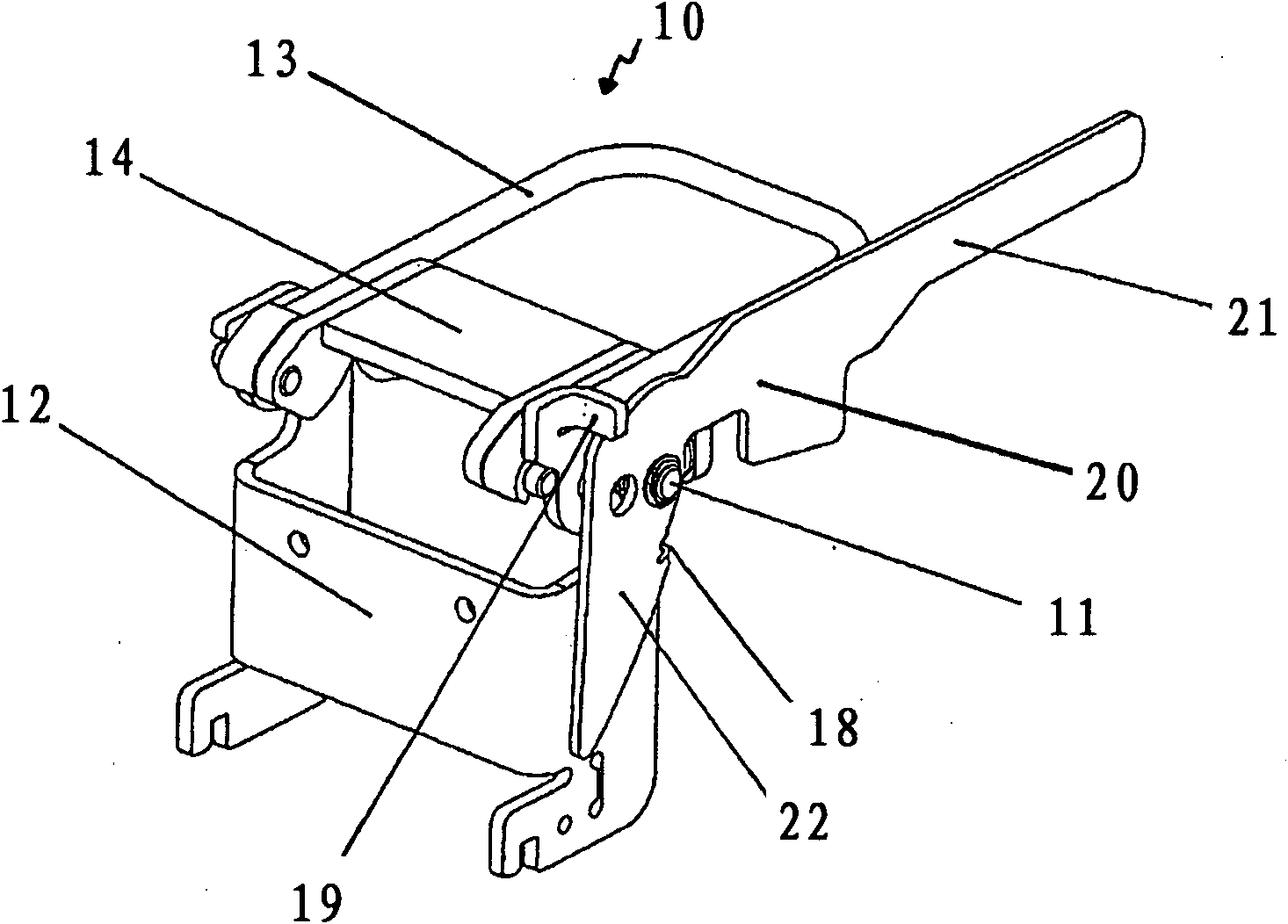

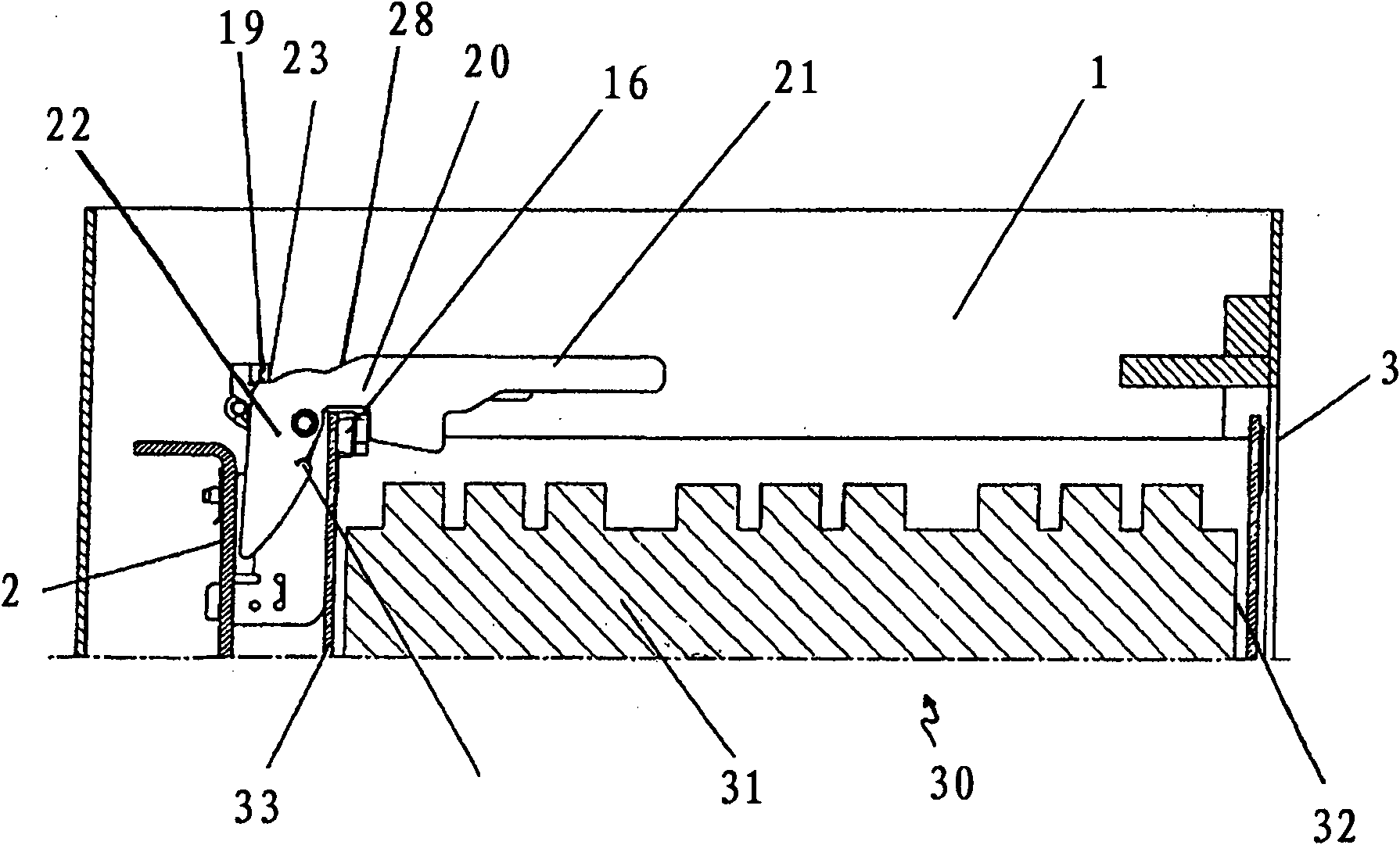

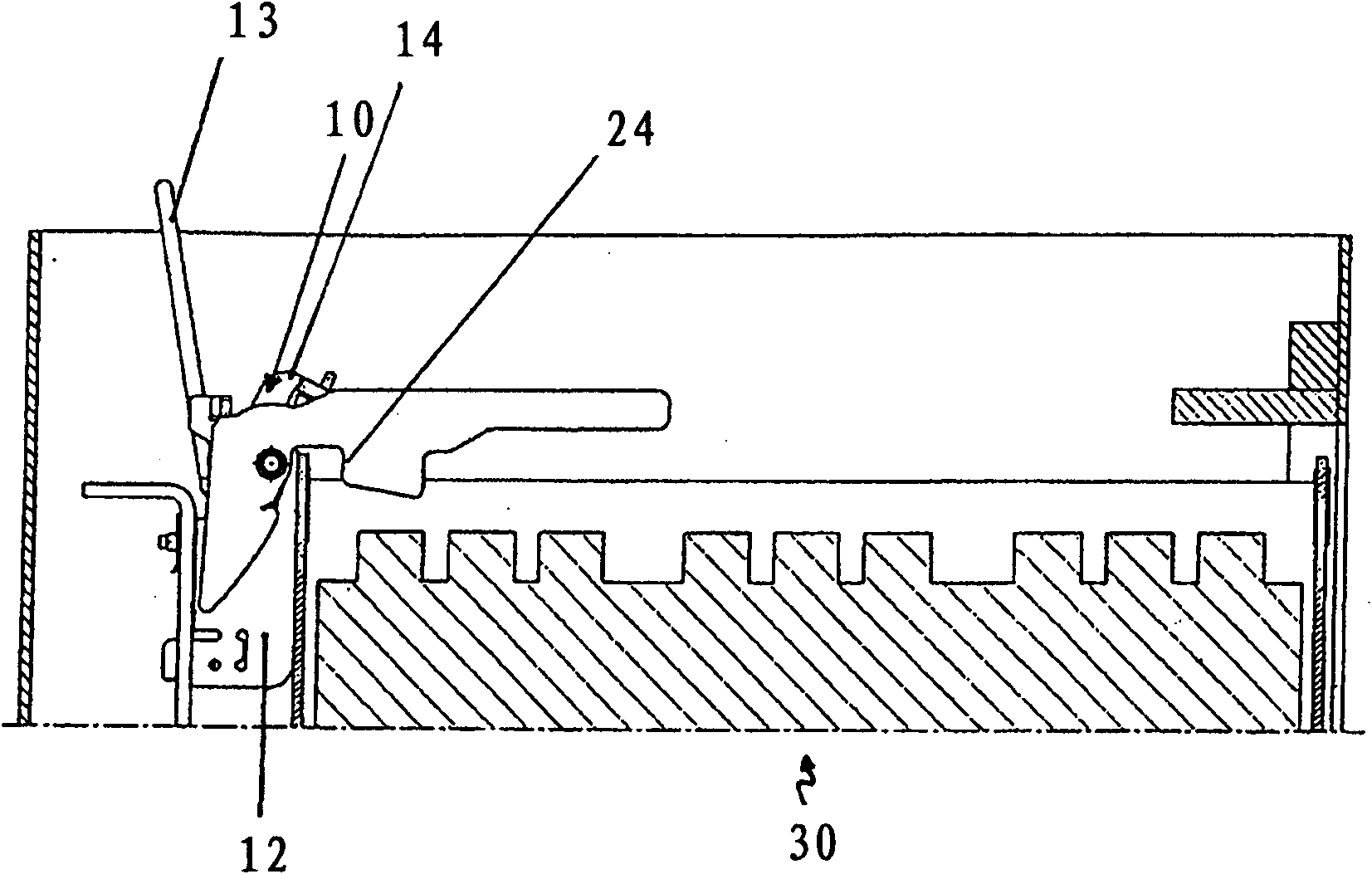

[0027] figure 1 A locking device is shown, which comprises a battery lock 10 and a removal lever 20 . The battery lock 10 has a support device 12 on which a first arcuate lever 13 is articulated. The second lever 14 is articulated to the first lever 13 by means of bearing bolts.

[0028] The removal lever 20 is mounted pivotably about the shaft 11 by means of screws connected to the support device 12 . The removal lever 20 has a first lever arm forming the handle section 21 and a second lever arm bent approximately at right angles relative to the first lever arm, which forms the lever section 22 . If the battery lock 10 is in the locked position, the handle section 21 is parallel to the first lever 13 of the battery lock 10 in the rest position of the removal lever. A stop 23 is formed on the end of the lever section 22 close to the shaft 11, and this stop 23 abuts against the corresponding stop 19 in the rest position of the extraction lever 20, which is formed by the bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com