Method and apparatus for the contactless measurement of an offset of the functional components of a travel path of a magnetic levitation railway driven by a linear motor

A technology of driving routes and linear motors, which is applied in the direction of measuring devices, motor vehicles, electromechanical devices, etc., can solve problems such as unsuitable for measuring functions, and achieve the effect of simplifying applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

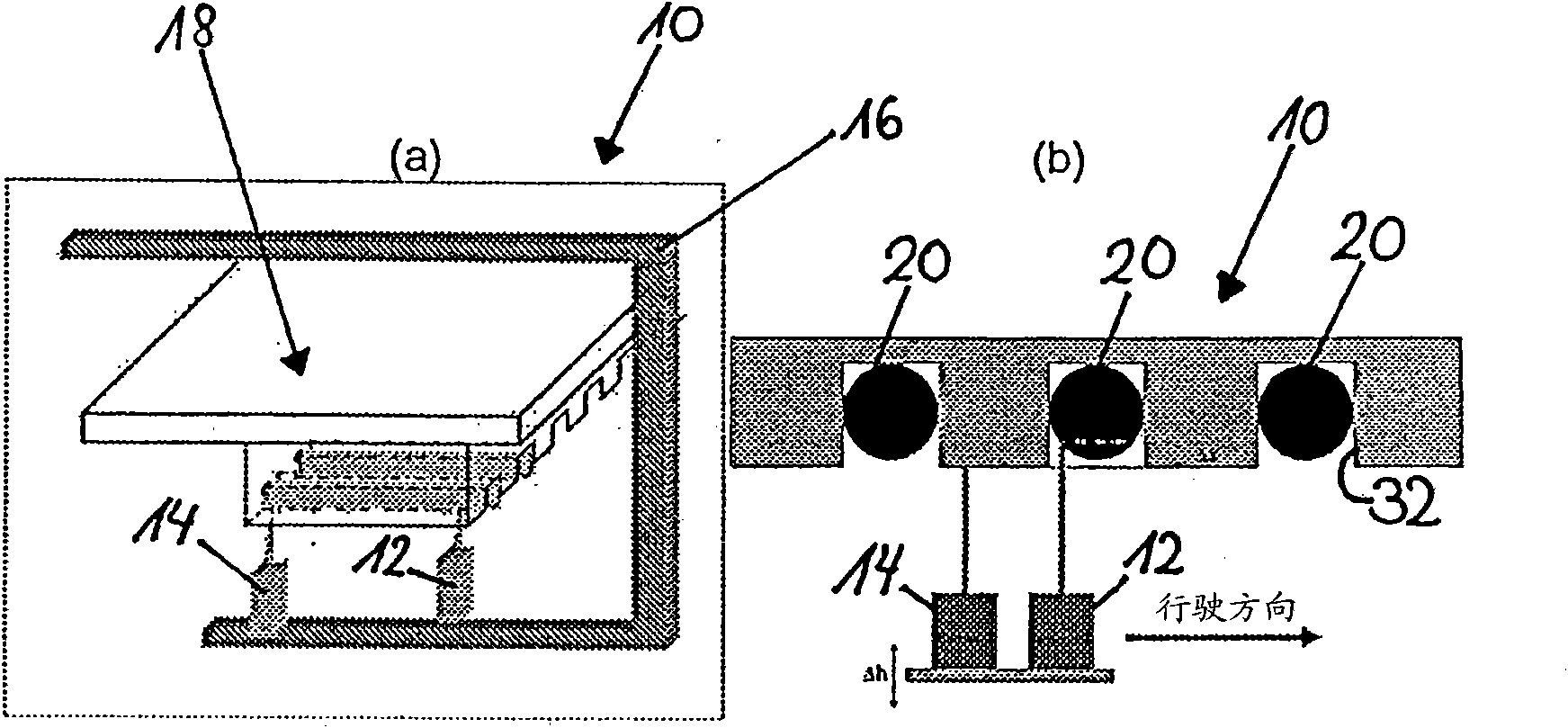

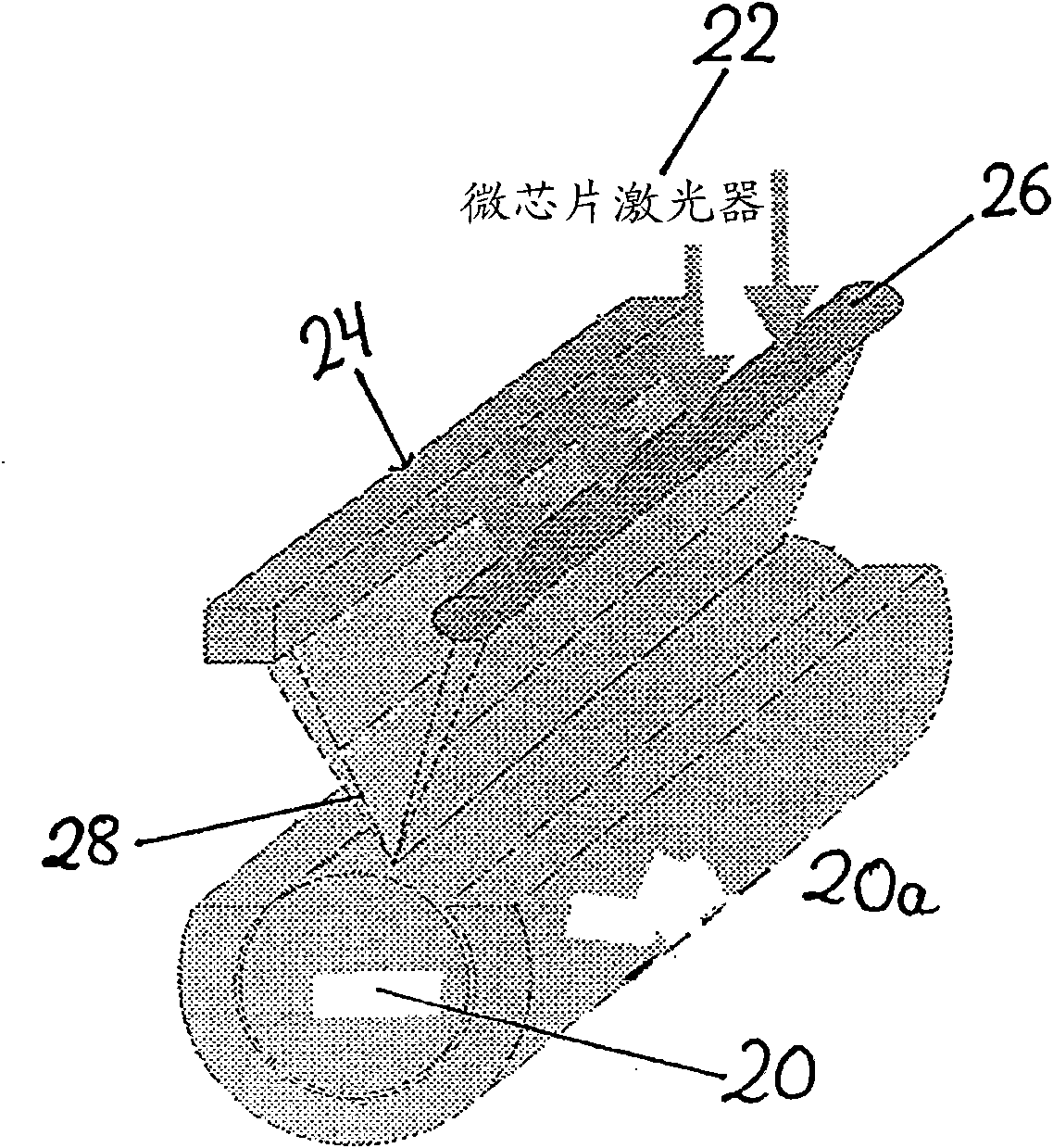

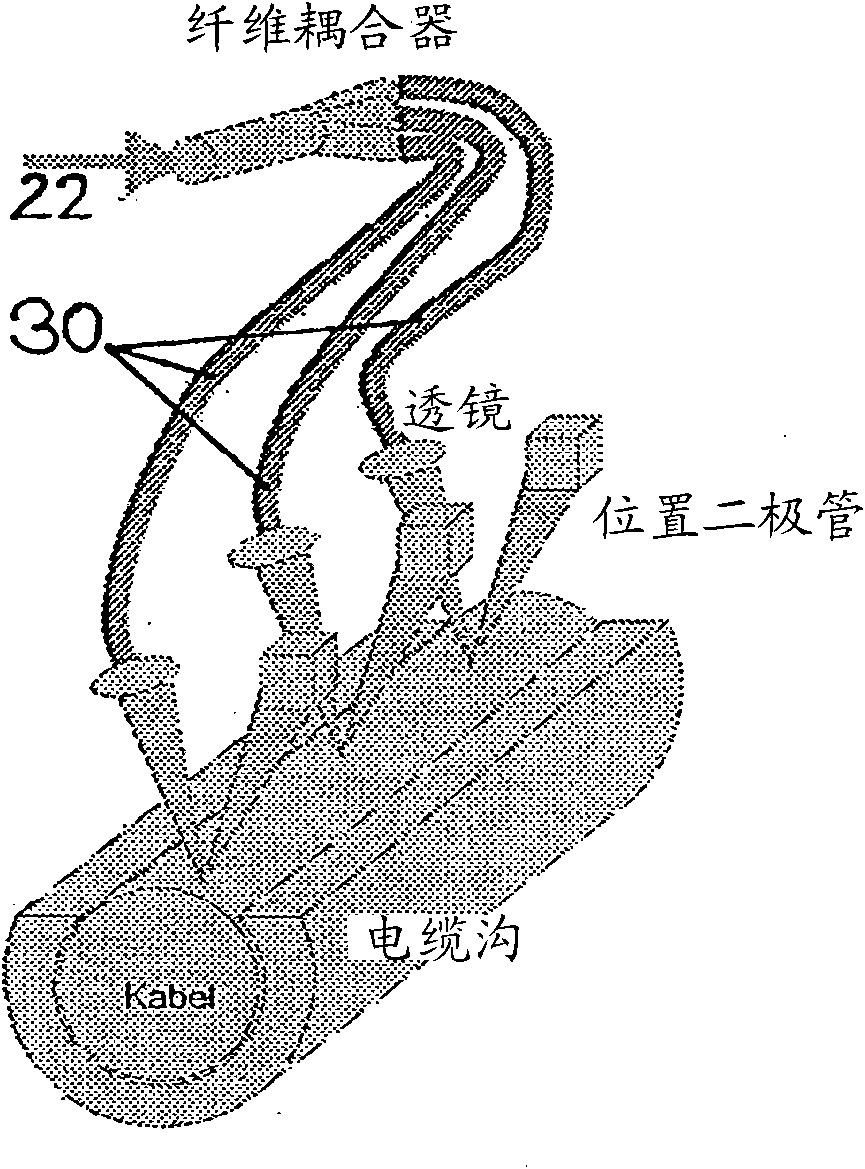

[0063] now by means of figure 1 6 through 6 describe various embodiments of the triangulation system 10 in detail. In this case, the same reference signs at least in principle always designate the same component parts.

[0064] Since this applies to all maglev rails, reference is made to maglev rail high-speed trains in this description here.

[0065] When monitoring the position of the motor winding in the stator laminations of the magnetic levitation track, possible vertical displacements of the stator cables 20 perpendicular to the stator laminations are checked in at least two different positions. The speed of the inspection vehicle and the measured speed in relation thereto shall be at least 100 km / h. The depth resolution is >30kHz.

[0066] exist figure 1 A scheme for optical triangulation to determine the position of the LSW or the position of the stator cables in a maglev track is shown in .

[0067] At least two sensors 12 and 14 are used which alternately operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com