Spray gun for dual-nozzle sprayer

A sprayer and dual-nozzle technology, applied in the field of spray guns for sprayers, can solve the problems of lack of a locking device, human injury, and inability to use normally, and achieve the effects of ensuring safety and reliability, reducing energy loss, and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

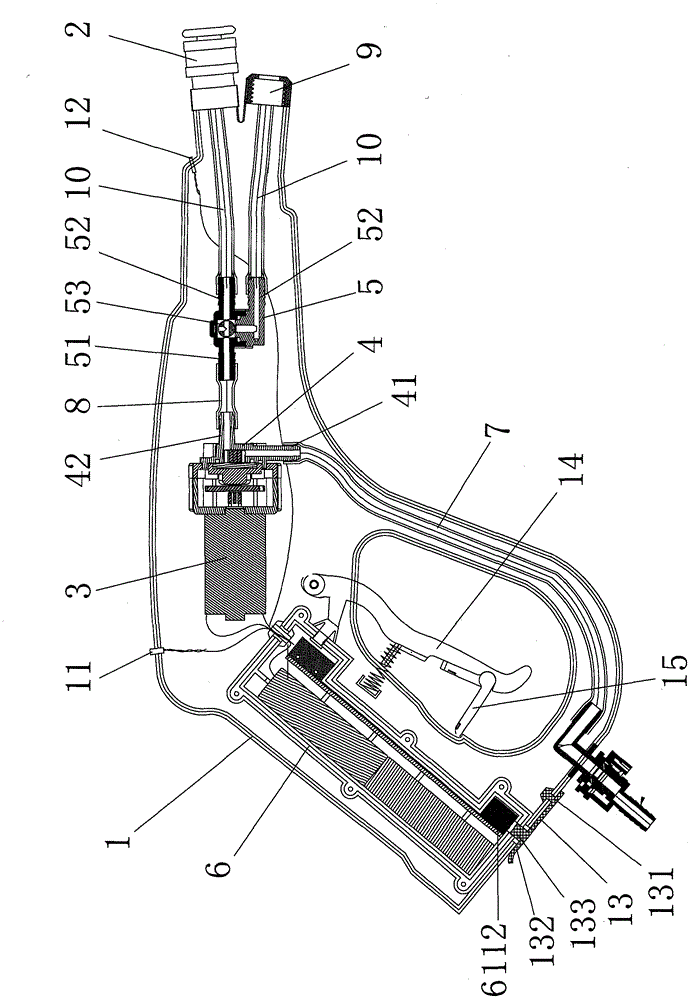

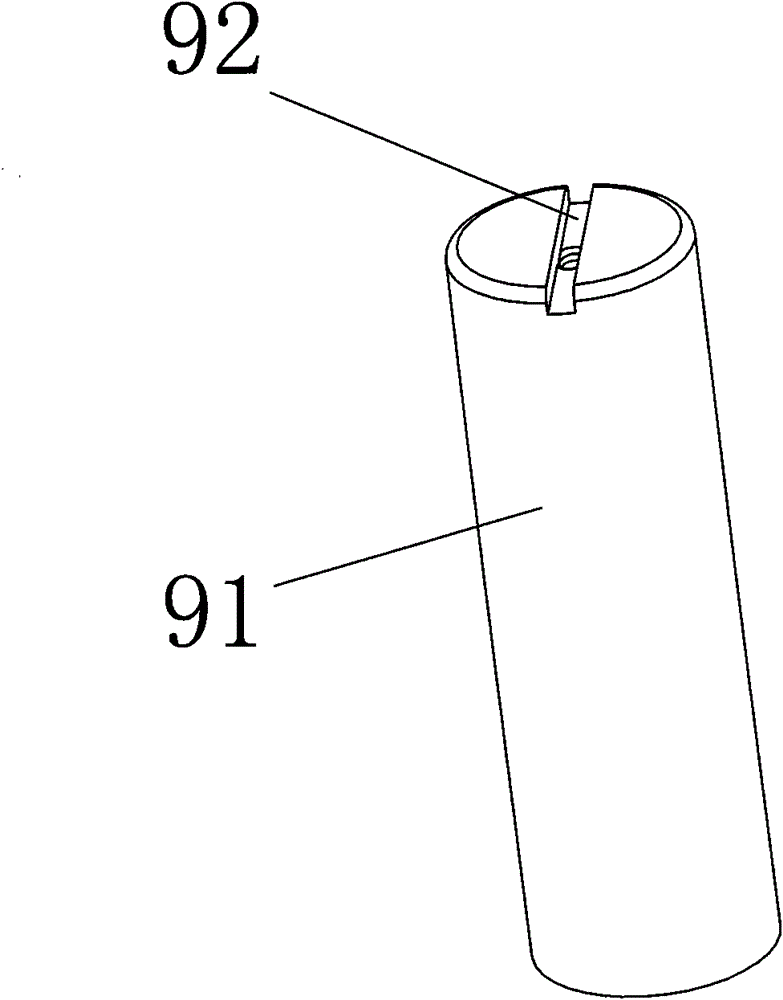

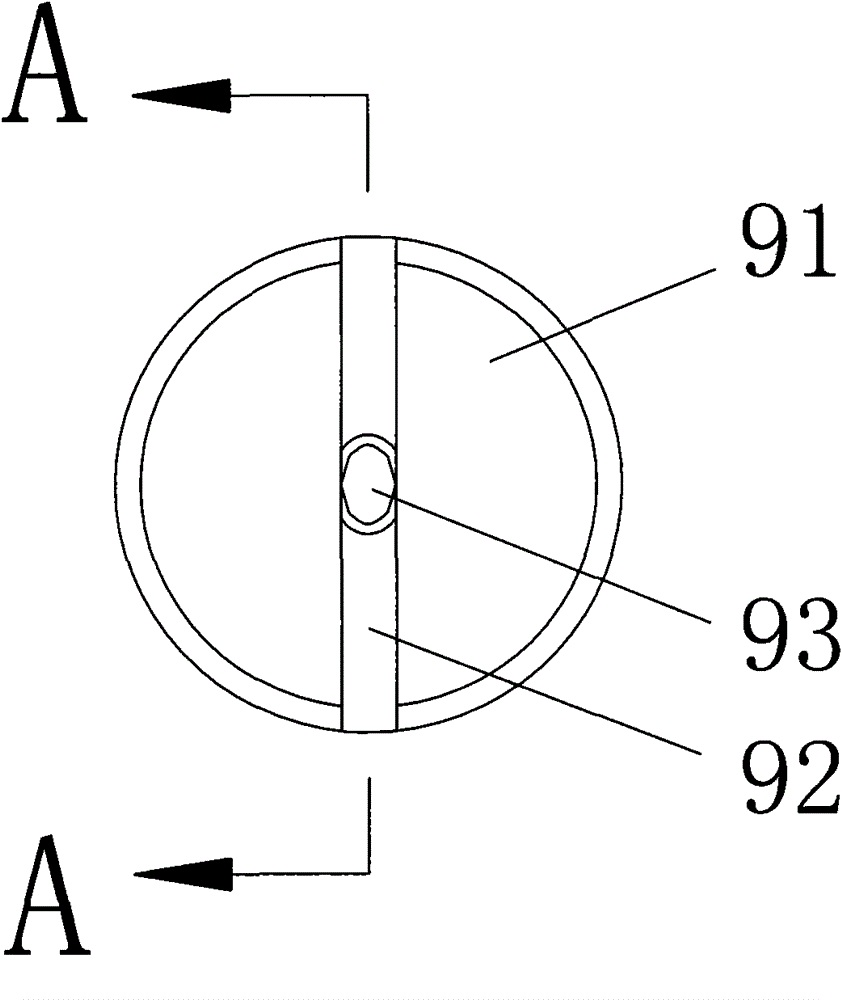

[0067] Example: such as figure 1 , Figure 8 with Figure 9 As shown, a spray gun for a double-nozzle sprayer includes a gun body 1 with a control wrench 14. The front end of the gun body 1 is provided with a fixed nozzle 9 arranged up and down correspondingly and a detachable quick-change nozzle 2. Inside the gun body 1 A motor 3, a pump 4, a control valve 5 and a power supply device 6 are provided. The above-mentioned control valve 5 is a three-way ball valve, which has a water inlet port 51 and two water outlet ports 52. The spool 53 of the control valve 5 is connected to There is a toggle button 54 exposed on the gun body. The water inlet pipe 7 of the gun body 1 is connected with the water inlet 41 of the pump 4, and the water outlet 42 of the pump 4 is connected with the water inlet interface 51 of the control valve 5 through the connecting pipe 8, and the two water outlet interfaces 52 of the control valve 5 are respectively It communicates with the quick-change nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com