Rotating creels for jacquard chain warpers, jacquard chain warpers and method for measuring bobbin diameters

A creel and warping machine technology, applied in the creel, warping machine, transportation and packaging, etc., can solve the problem of yarn material consumption, to ensure high precision, fast and uniform movement, high reliability and precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

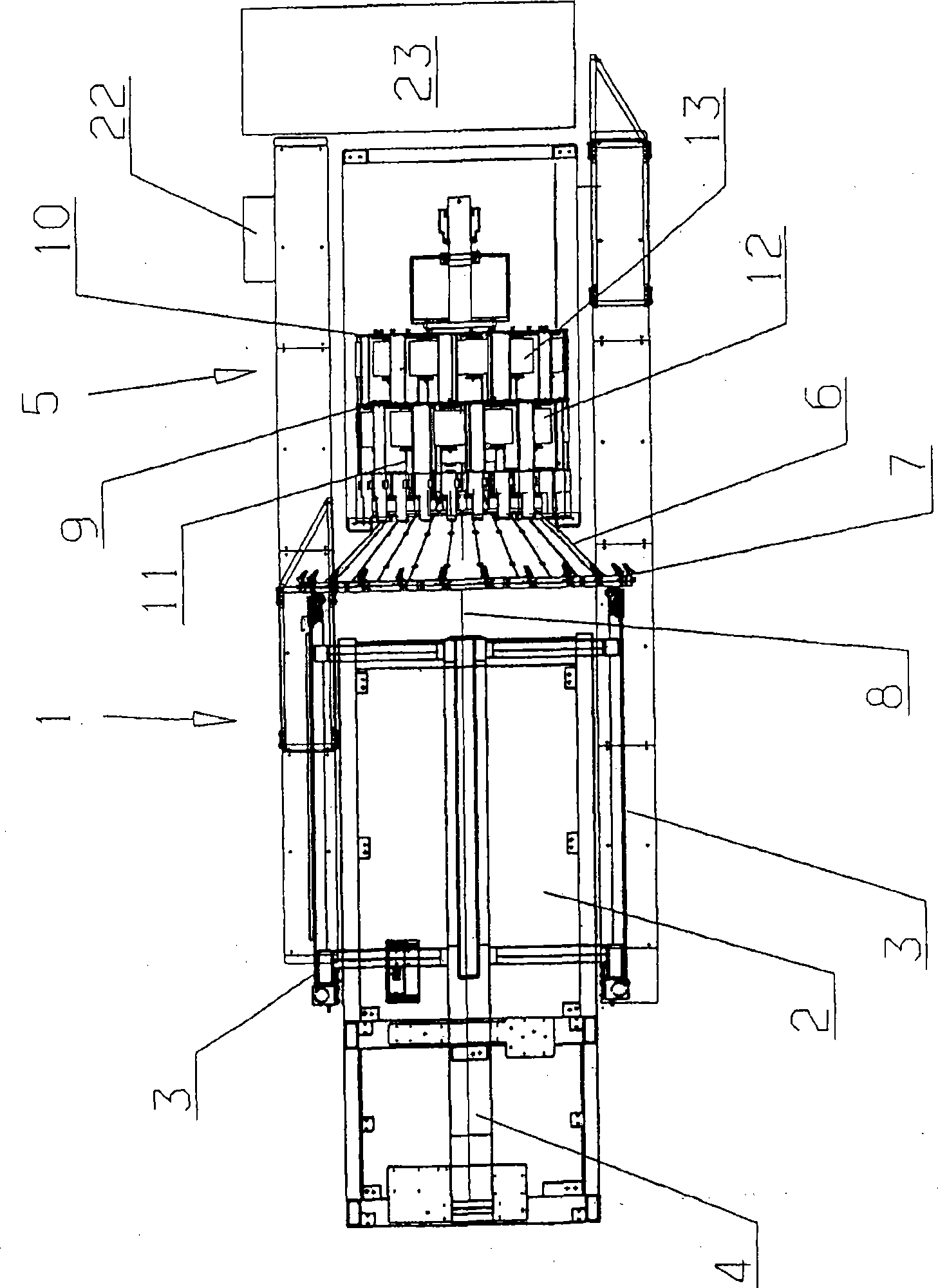

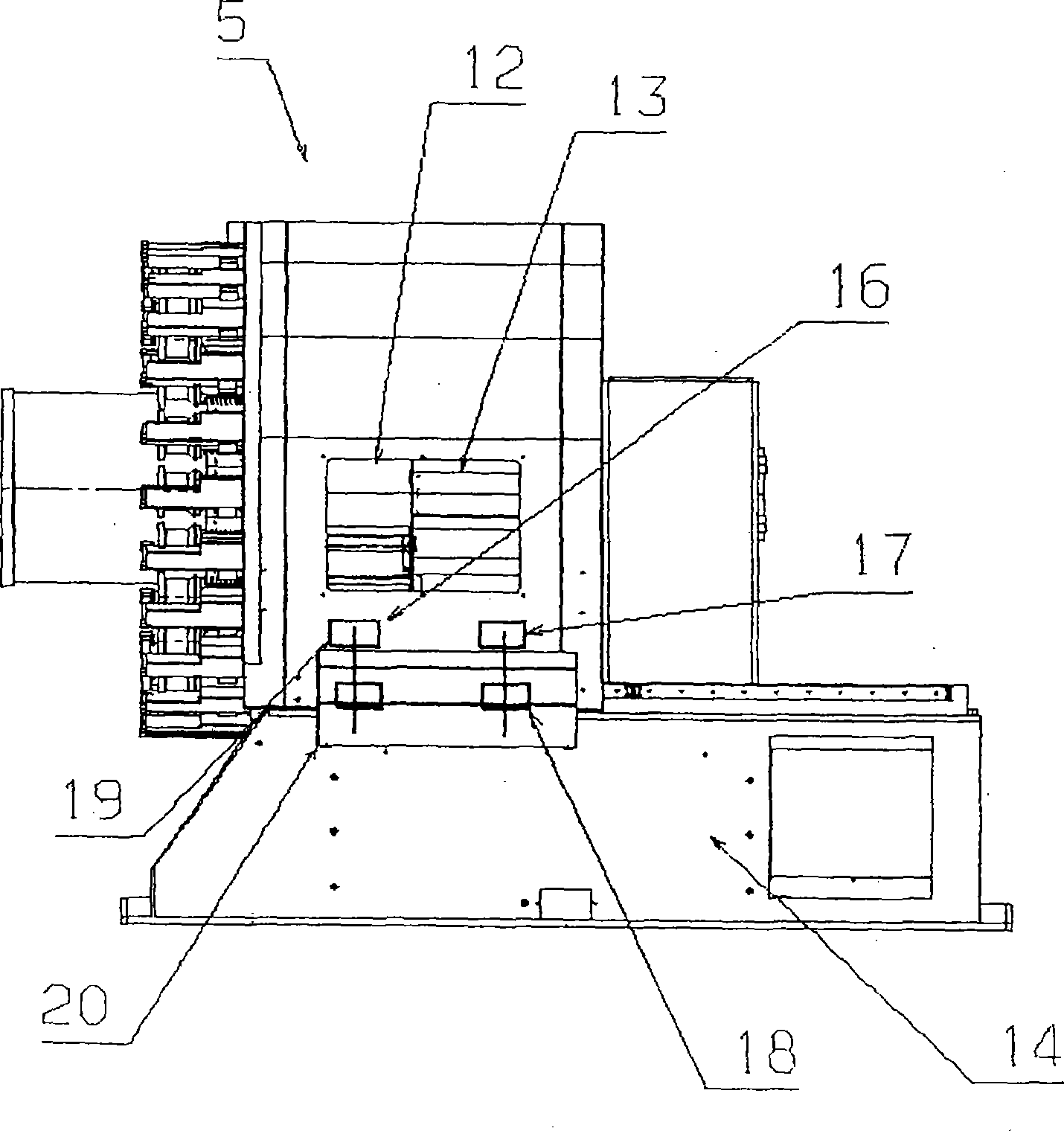

[0034] figure 1A Jacquard chain warper 1 is shown with a large warping drum 2 , a plurality of conveyor belts 3 being arranged on the circumference of the warping drum 2 . The conveyor belt 3 is parallel to an axis 4 of the large warping drum 2 . The large drum 2 of the warping machine is set to be rotatable. The yarn is of course prevented from turning while winding the yarn.

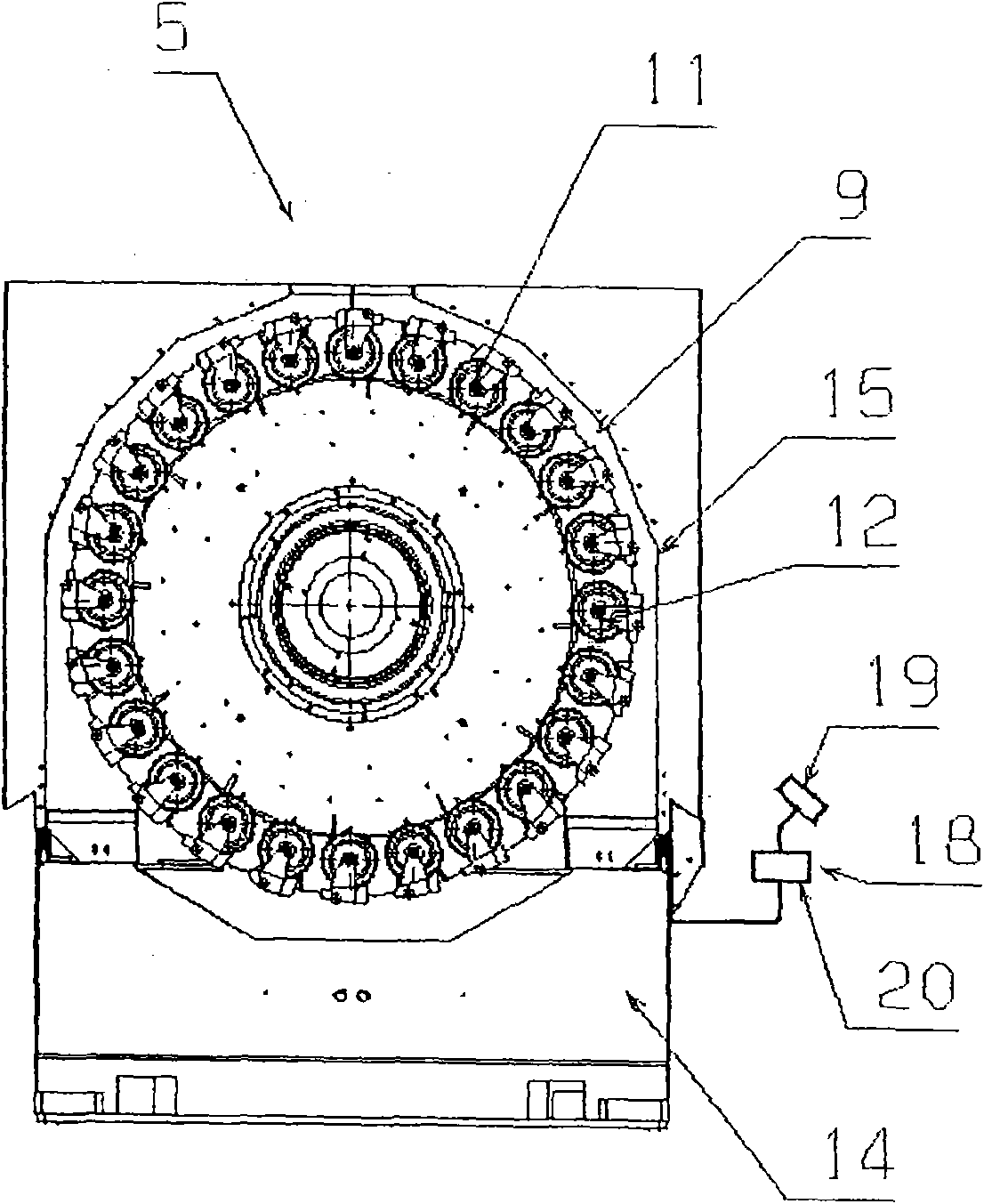

[0035] A rotating creel 5 is arranged opposite to the end face of the large cylinder 2 of the warping machine. Yarns 6 are withdrawn from the rotating creel 5 , and these yarns can be placed on the conveyor belt 3 by means of yarn guides 7 . The thread guide 7 can pivot on the conveyor belt 3 in the axial direction of the warping drum 2 . In this case, the yarn 6 is placed on the conveyor belt 3 . The yarn guide 7 can also be pivoted in such a way that it lays the yarn 6 on an intermediate rope 8 which extends approximately on the axis 4 of the large warping drum 2 .

[0036] In order for the yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com