Trapped vortex tail wing carburetor of throttle

A technology for a throttle valve and a carburetor, which is applied to the field of a throttle valve trapped vortex tail carburetor, can solve the problems of the intake pressure loss of the combustion chamber and the decrease of the engine power, so as to reduce the airflow pressure loss, improve the degree of mixing, and improve the structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

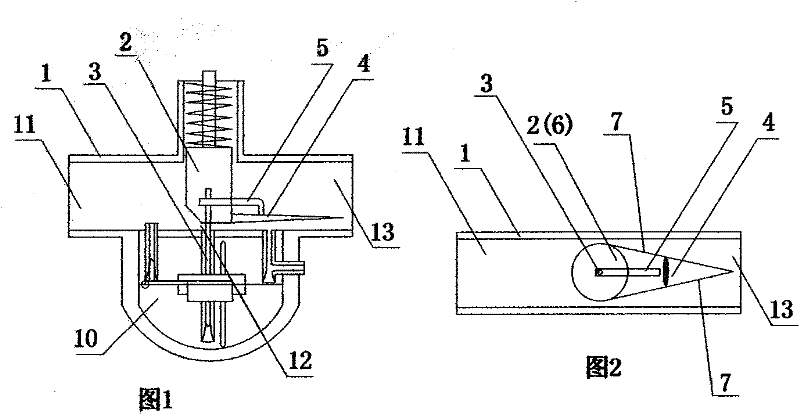

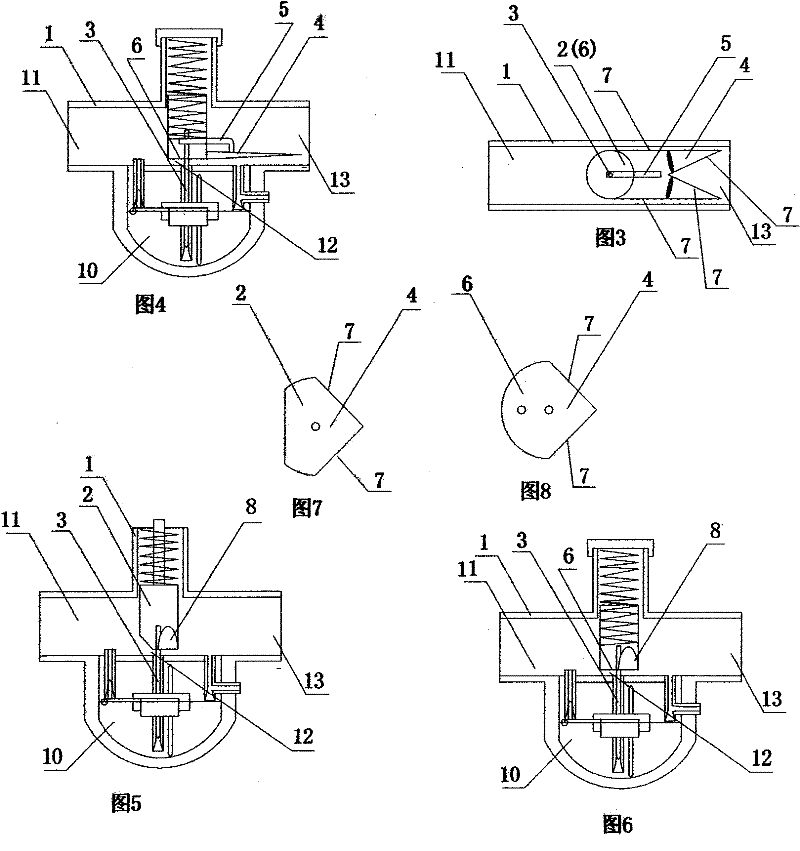

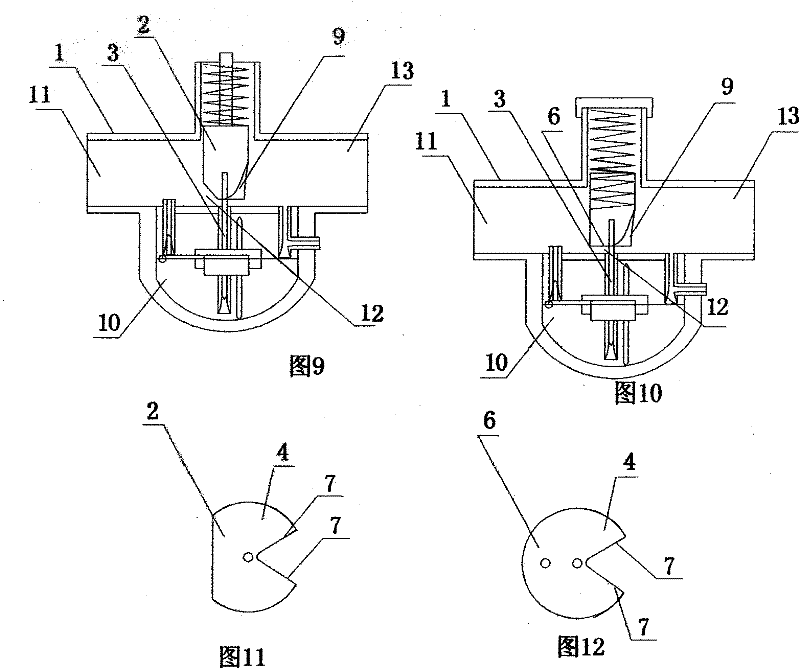

[0018] exist figure 1 In the shown first embodiment, the vortex tail (4) is a triangular piece, arranged behind the plunger throttle (2), the lower bottom surface of the vortex tail (4) is in contact with the plunger throttle (2) The bottom surface of the connecting rod (5) is connected to the upper surface of the vortex empennage (4), and the other end has a connecting hole, and the end with the connecting hole is inserted into the rear wall of the plunger throttle (2), and the oil needle ( 3) Connect the vortex tail (4) to the rear wall of the plunger throttle (2) through the connecting hole on the connecting rod (5). like figure 2 As shown in the triangular sheet-shaped vortex tail (4), the root of the triangular side is an arc line close to the rear wall of the plunger throttle (2), and the width of the root is equal to the diameter of the plunger throttle (2) or the outlet The width of the passageway (13), the other two sides of the triangle constitute two edge lines (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com