Automobile high prefilter

A pre-filter, high-level technology, applied in the direction of fuel air filter, etc., can solve the problems of high resistance and large space occupation, and achieve the effect of good use effect and high pre-filter efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

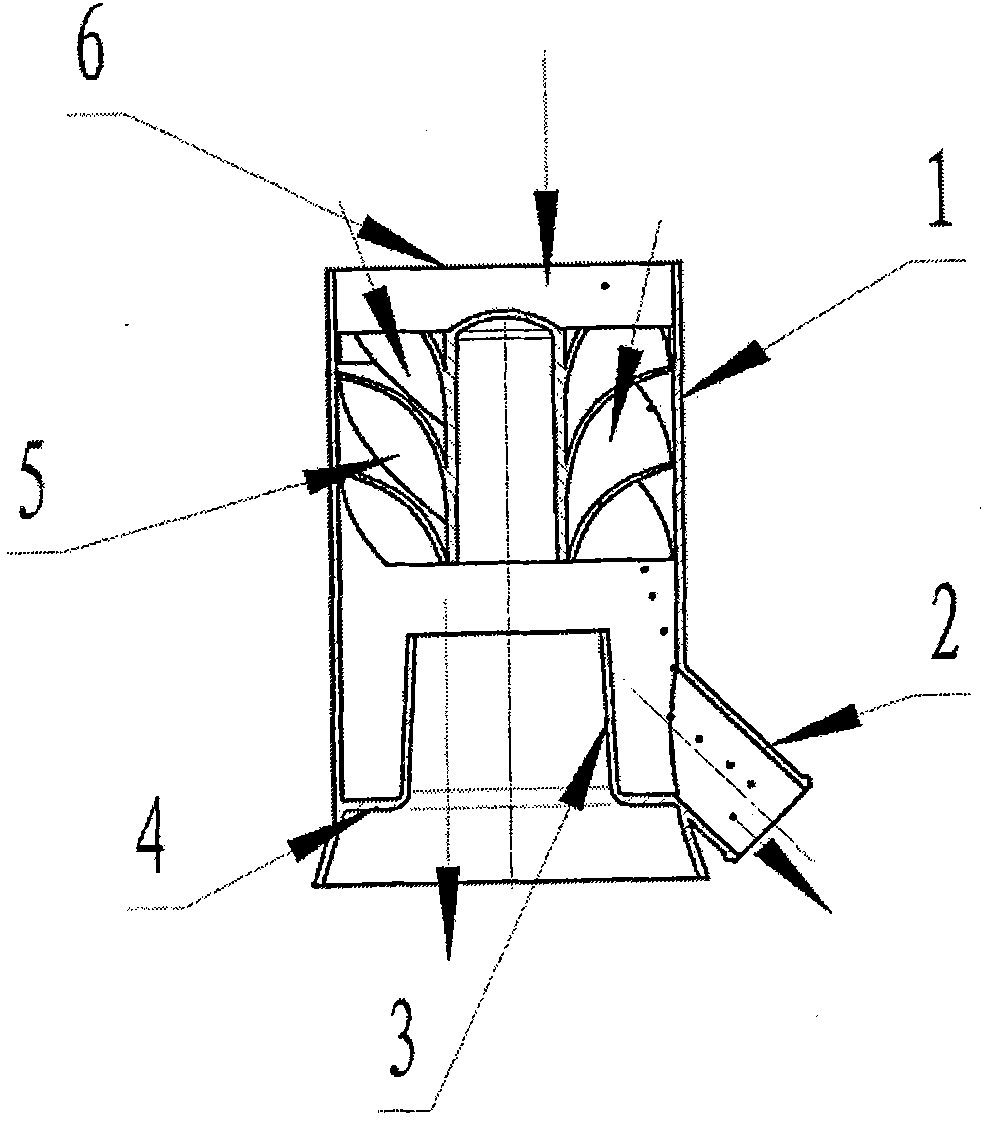

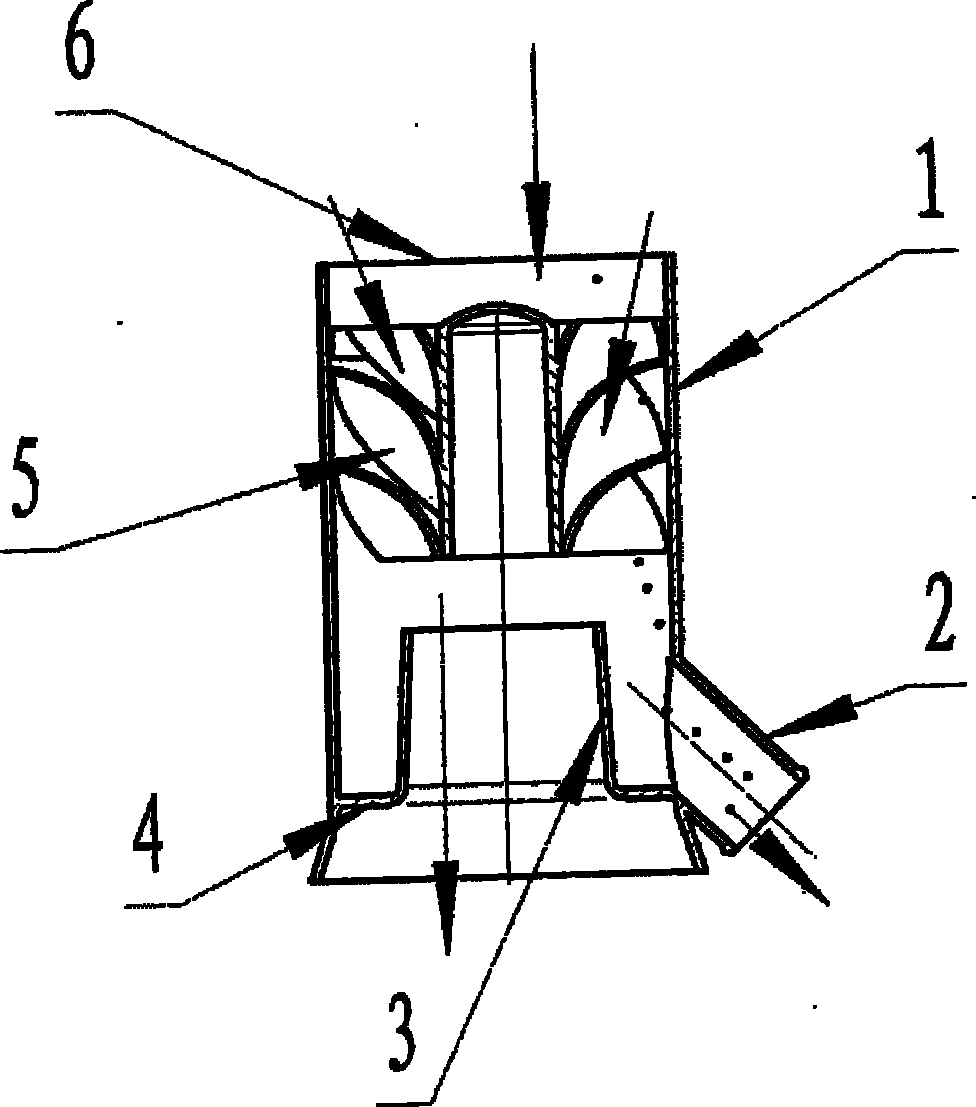

[0009] Such as figure 1 Shown, the present invention is provided with air inlet 6 on housing 1, and housing 1 bottom is provided with dust discharge pipe 2, prefilter bottom surface 4 and air outlet 3, and the inner side of air inlet 6 is provided with blade ring 5.

[0010] The air entering the pre-filter from the air inlet 6, when passing through the blade ring 5, due to the swirling effect of the blade ring 5, the air performs a spiral motion in the housing 1, and the component of its motion speed in the circumferential direction forms a centrifugal force, which will The large particles in the dust entering the pre-filter are thrown onto the inner wall of the housing 1 and move spirally towards the bottom surface 4 of the pre-filter along the inner wall of the housing 1 under the action of the airflow. The connection with the shell 1 makes a circular motion, and is removed from the pre-filter in the dust discharge pipe 2, thereby realizing coarse filtration. Since the blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com