Combustor fire cover for gas stove and combustor of gas stove thereby

A technology for burners and gas stoves, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of influence, the user spends a long time to cook, and the area where the fire holes are distributed is limited, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

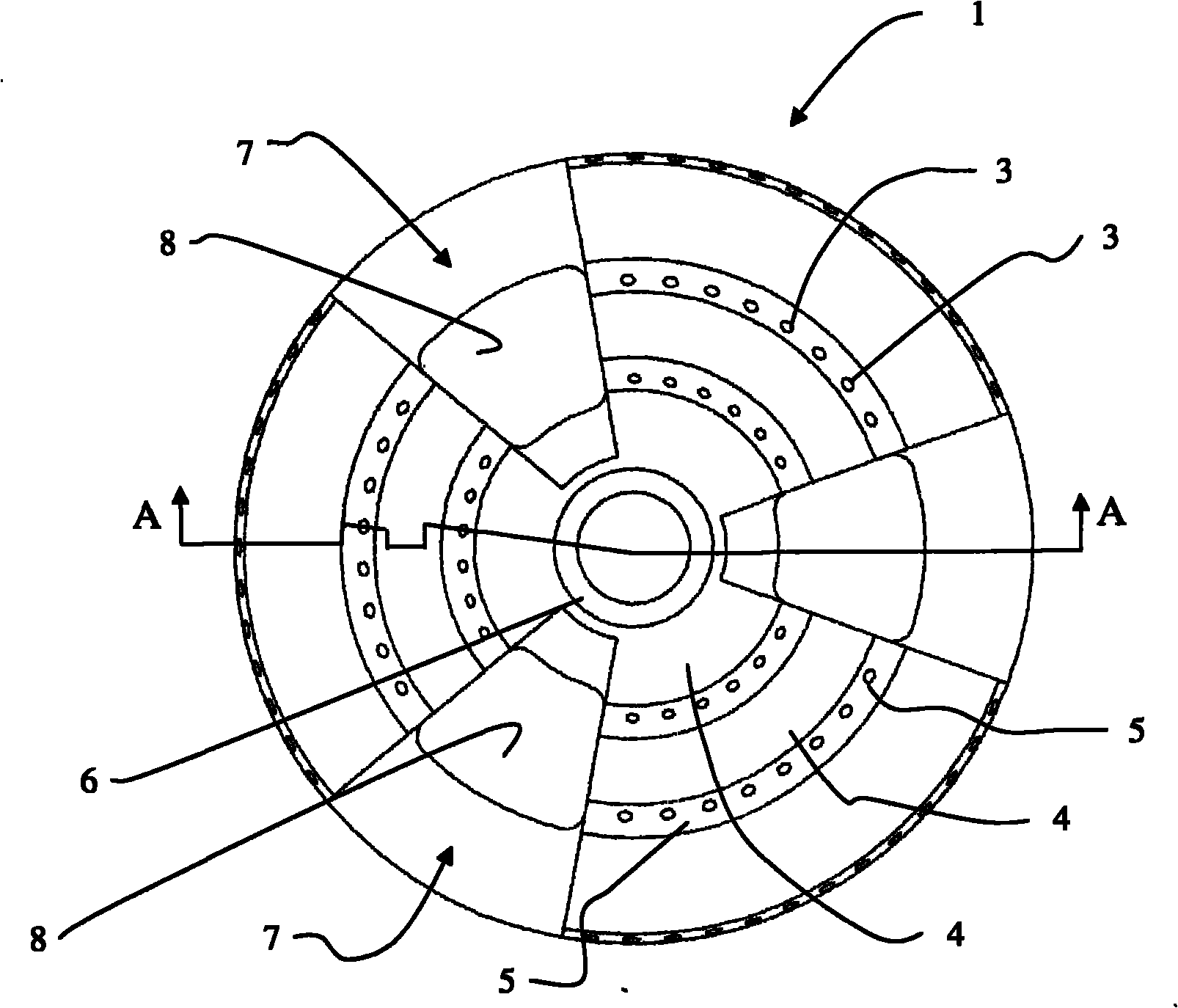

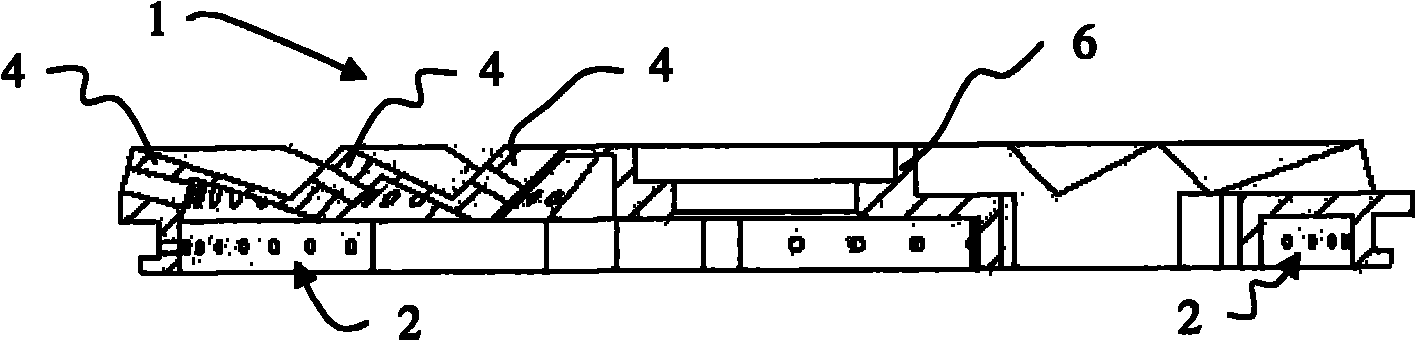

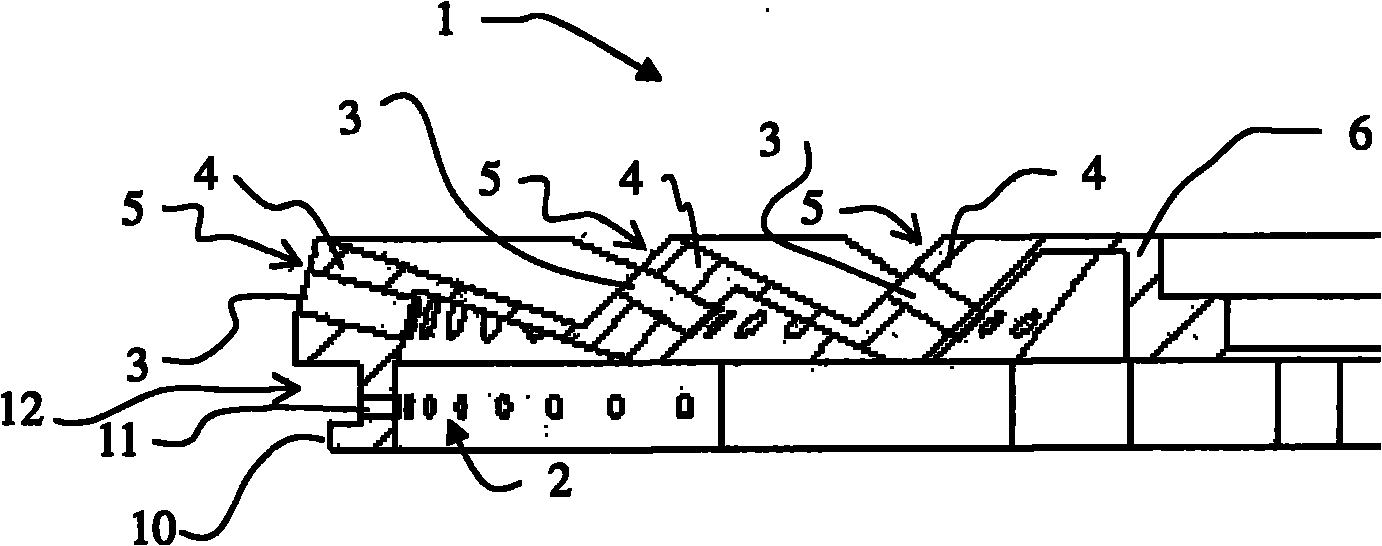

[0031] See attached Figure 1 to Figure 4 , the present invention provides a burner fire cover 1 for a gas stove, comprising a cover body 1 with a substantially circular shape and a base surface 9 of the cover body. The lower side of the cover body is recessed to form the cover body air chamber 2 . The cover is provided with a fire hole 3 penetrating the cover. At least one peak undulation 4 concentric with the cover is formed on the base surface of the cover. The peak undulation 4 comprises at least two discontinuously distributed peak undulation segments. Each of the peak-shaped undulating sections is formed with an outer slope 5 facing away from the center of the cover body. A fire hole 3 is arranged on the outer slope surface 5 . By setting at least one peak-shaped undulation 4 formed by at least two peak-shaped undulating sections concentric with the cover on the cover base surface of the burner fire cover, at the same time, the peak-shaped undulating segment is away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com