Full-scale derailing principle test stand with steering frame operating on rails

A bogie, full-scale technology, applied in the direction of railway vehicle testing, etc., can solve the problem that the characteristics of wheel-rail interaction cannot be reflected, and achieve the effects of short cycle, convenient test and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

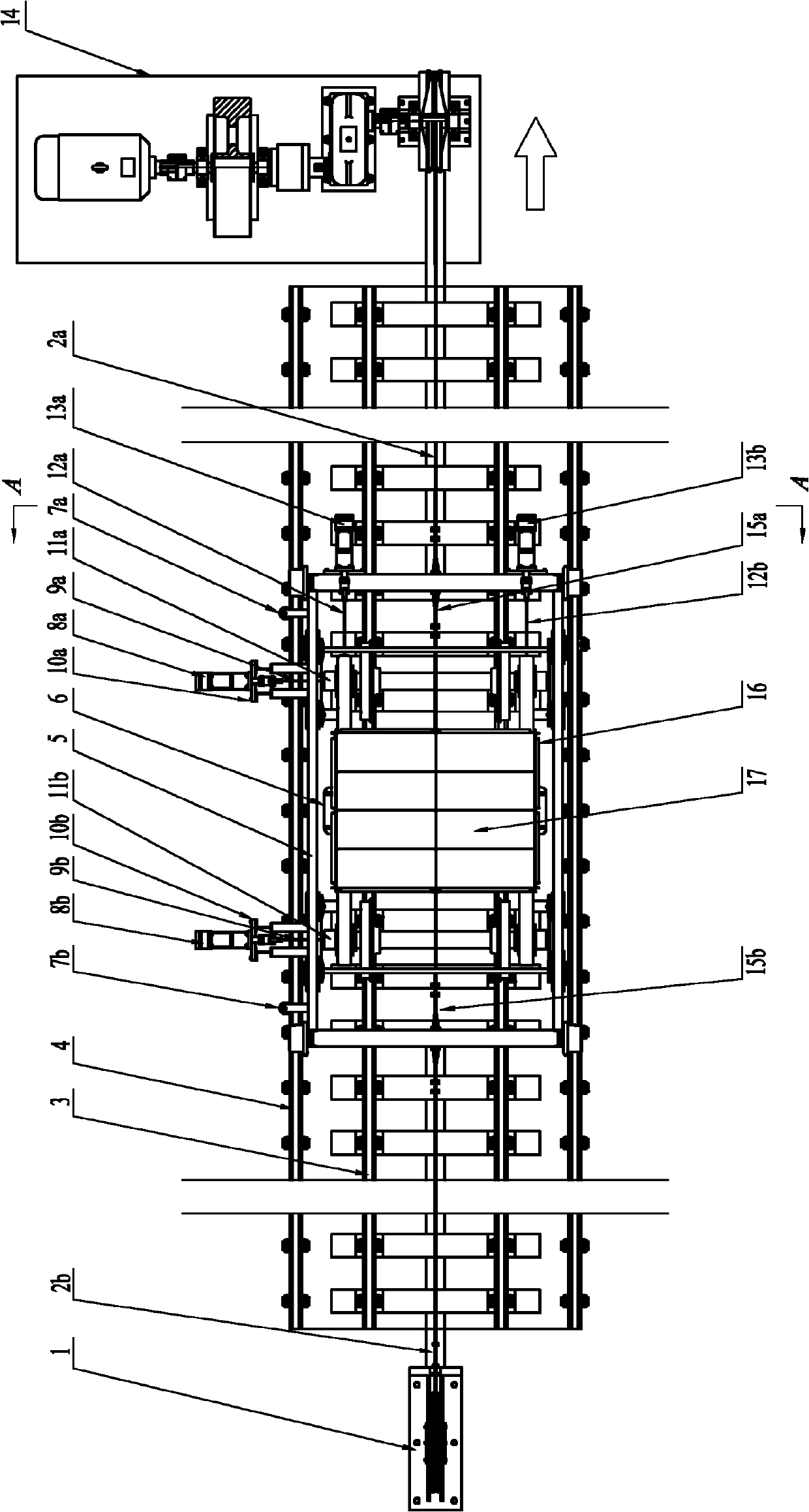

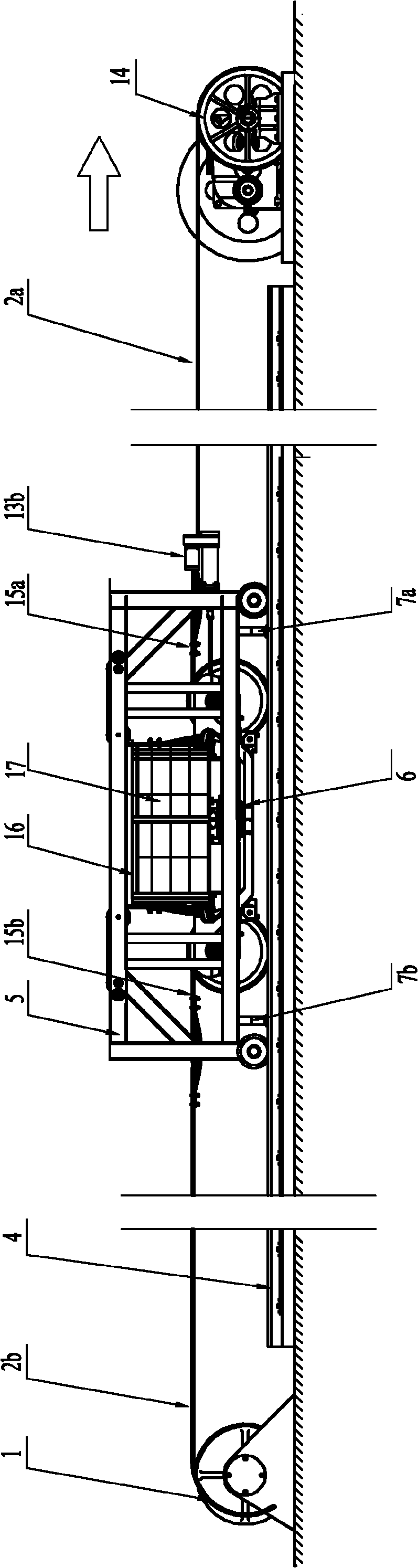

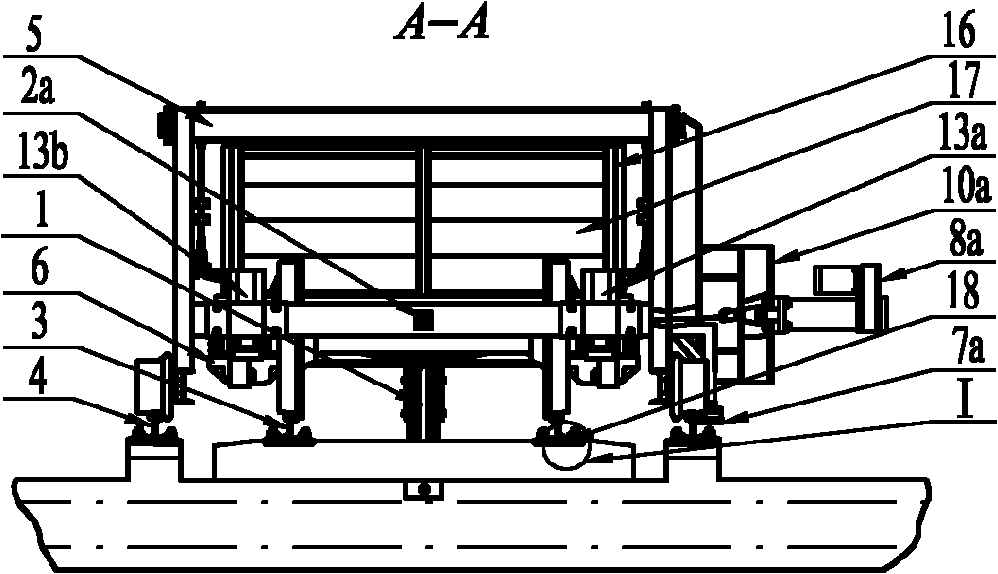

[0029] Figure 1~3 It is shown that a specific embodiment of the present invention is: a full-scale derailment mechanism test bench with a bogie running on a track, including a railway track 3 for testing and a bogie 6 for testing placed on the railway track 3 . The outside of the railway track 3 is provided with a tractor guide rail 4, the tractor guide rail 4 cooperates with the wheels of the traction trolley 5, the bogie 6 is placed in the traction trolley 5, and the front and rear of the bogie 6 are connected to the traction trolley 5 through steel wire ropes 15a, 15b The driving device 14 in front of the railway track 3 links to each other with the front end of the traction trolley 5 through the wire rope 2a; It is connected to the front and rear axle boxes 11a and 11b on the left side of the bogie 6; the cylinder rods of the left and right longitudinal electric cylinders 13a and 13b at the front of the traction trolley 5 are connected to the bogie 6 through the respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com