Pipe temperature change test unit

A technology of temperature change and test equipment, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of inability to ensure effectiveness and achieve the effects of convenient operation, improved inspection effect, and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

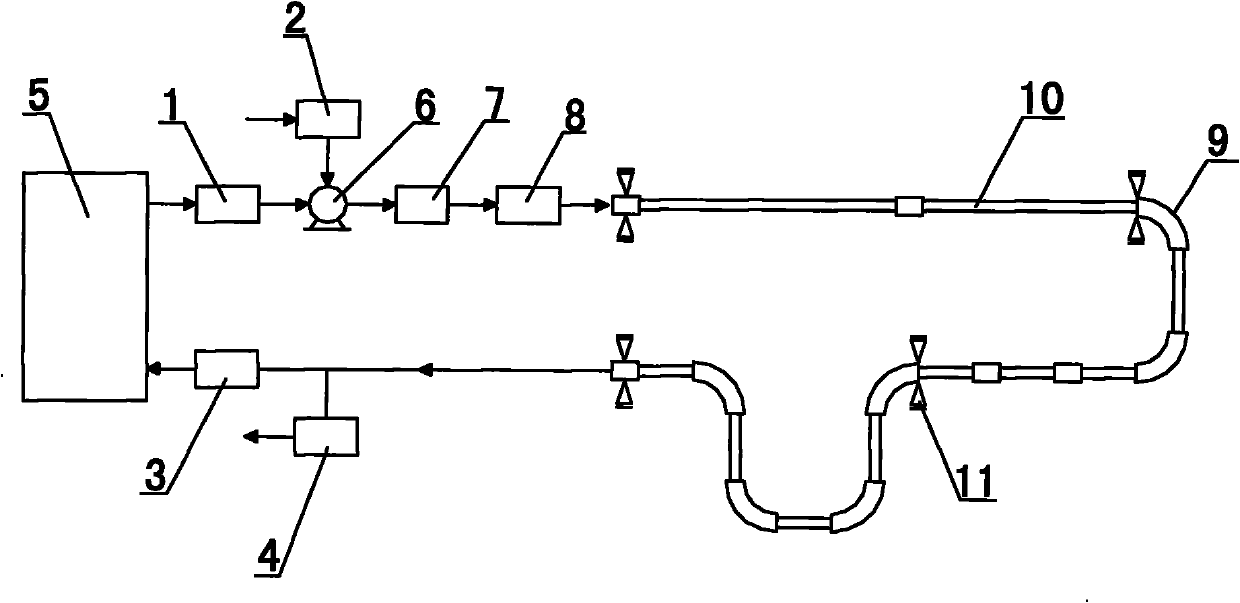

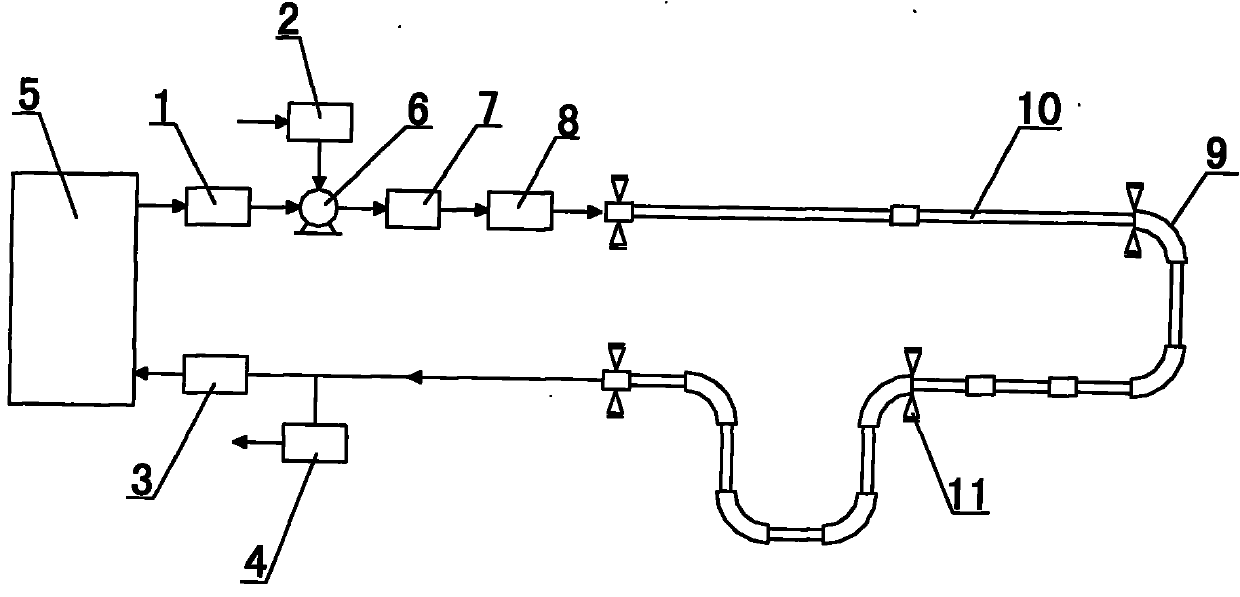

[0011] Such as figure 1 As shown, the pipe temperature change test device of the present invention includes a solenoid valve I1, a solenoid valve III3, a water pump 6, a pressure valve 7, and a thermal sensor 8. The output end and the input end of the water heater 5 are respectively connected to the solenoid valve I1 And electromagnetic valve III3, wherein the other end of electromagnetic valve I1 is provided with water pump 6, and this water pump 6 is connected with electromagnetic valve II2 and pressure valve 7 respectively, and electromagnetic valve II2 is connected with cold water inlet end; The output end of described pressure valve 7 is provided with heat Inductor 8, one side of the thermal sensor 8 is connected to the pipe to be detected 10, pipe joints 9 are connected between each section of pipe 10, a fixed bracket floating support 11 is provided on the outside of the pipe 10, and the solenoid valve III3 is externally provided with a Solenoid valve IV4 for cold water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com