Rivet gun with improved action structure

A nail gun and action technology, which is applied in the field of pull nail guns with improved action structure, can solve the problems of overlapping or interference of driving devices, unsuitable space, long axial length of the pull nail gun, etc. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

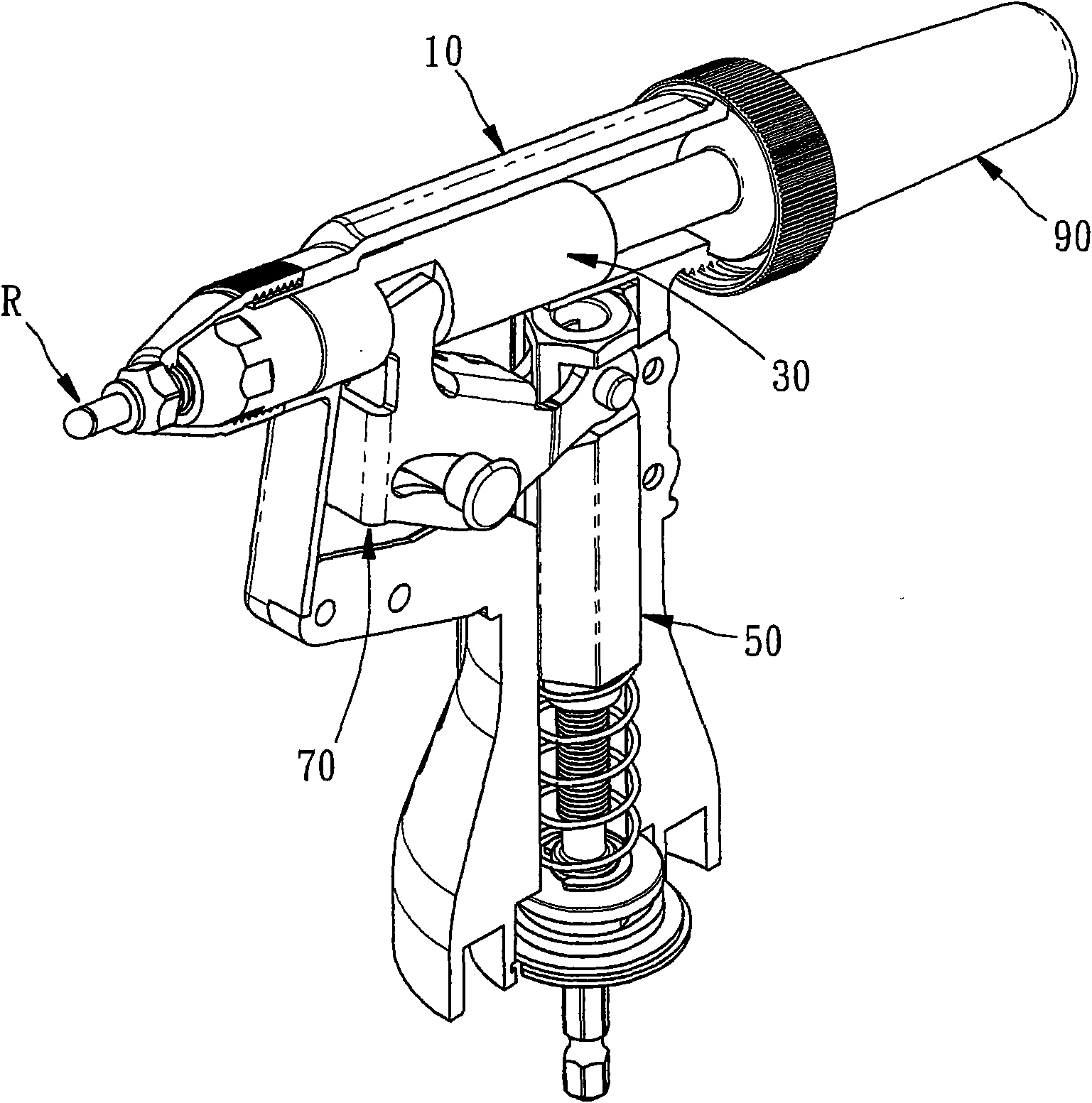

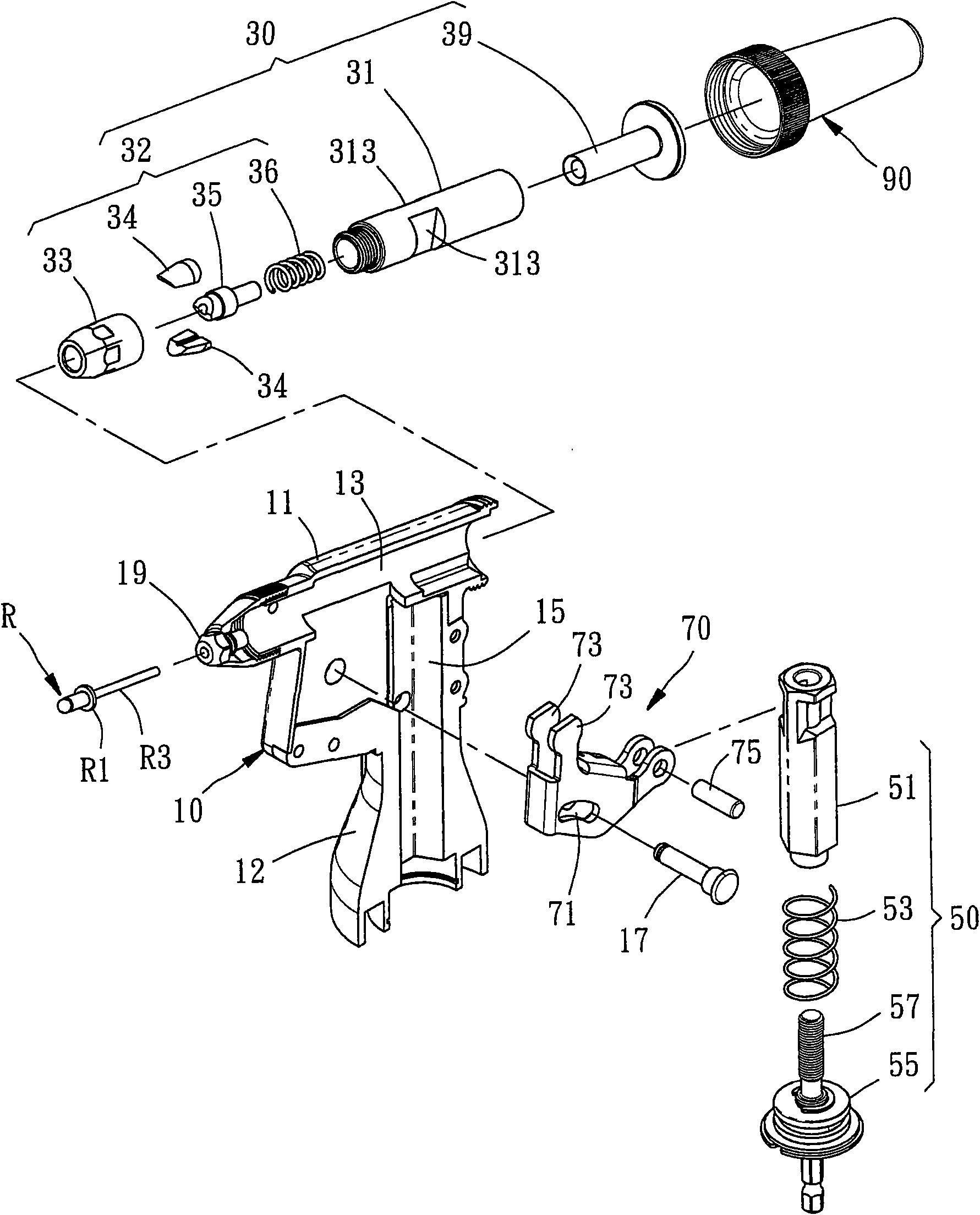

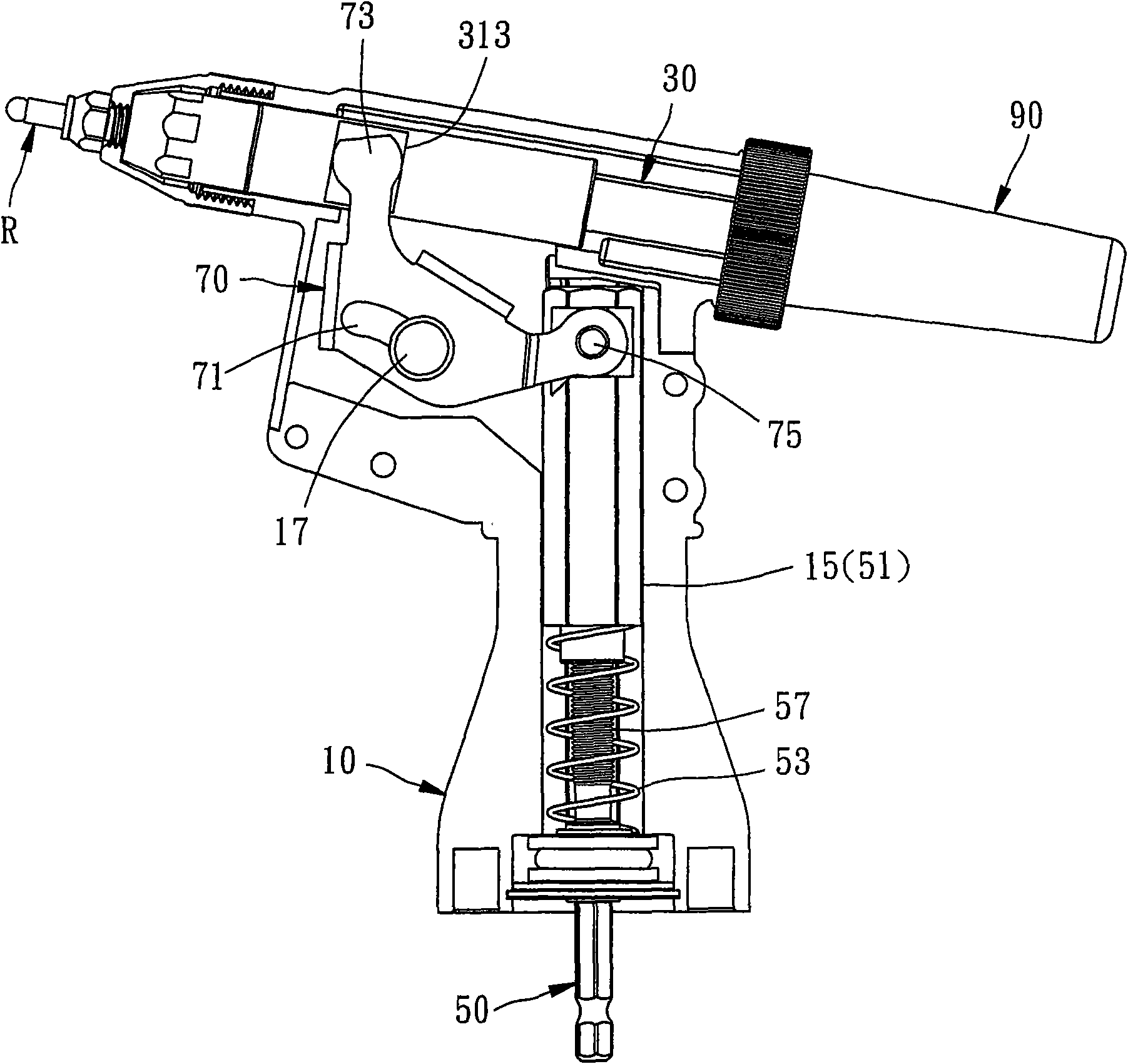

[0021] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

[0022] Such as Figure 1 to Figure 5 As shown, it is a rivet gun with improved action structure provided by a preferred embodiment of the present invention, which is used to pull a rivet R. The rivet R has a nail tube R1 and a nail rod R3. The rivet gun includes :

[0023] A gun group 10 has a shaft fitting part 13, a moving control fitting part 15, a moving group limiting part 17, and a nailing part 19 for installing a rivet R. Wherein the gun group 10 consists of a gun barrel 11 and a gun handle 12 connected to the gun barrel 11 at a predetermined angle, the shaft fitting part 13 is located at the gun barrel 11, and the shifting control fitting part 15 is arranged on the gun handle 12.

[0024] A pull rod group 30 has a shaft tube 31, the shaft tube 31 can be axially displaced along the shaft fitting part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com