Compact high-voltage power quality optimization device

A high-voltage electric energy and optimization device technology, applied in the direction of circuit devices, electrical components, AC network circuits, etc., can solve the problems of unable to monitor power quality in real time, low utilization rate of equipment power density, waste of space, etc., to achieve both system voltage support, The effect of improving space utilization and increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

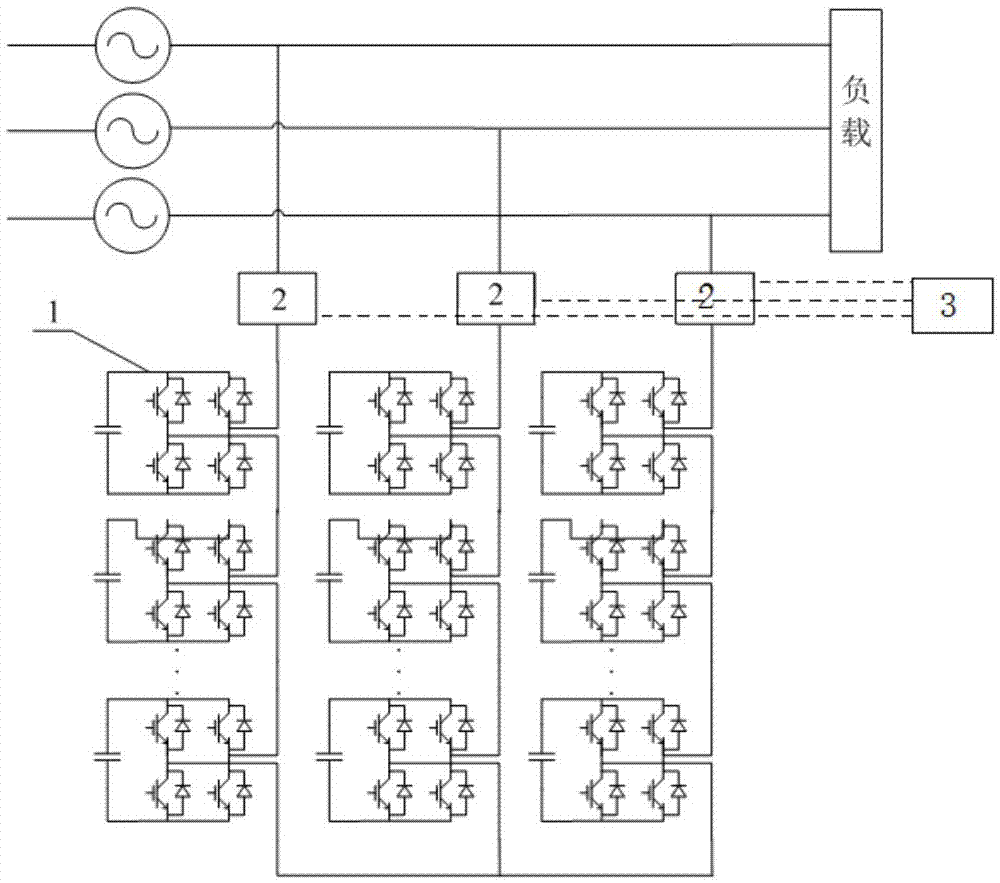

[0020] Such as figure 1 As shown, a compact high-voltage power quality optimization device includes a three-phase cascaded H-bridge and a power compensator 2 connected to the three-phase cascaded H-bridge, and each phase of the three-phase cascaded H-bridge consists of multiple H-bridge power units 1 are cascaded, and each of the H-bridge power units 1 includes four power devices, and each power device includes a reactor and a radiator installed on the reactor. The outside of the reactor is sealed with insulating sealant, and each H-bridge power unit 1 is arranged in the same electrical cabinet, and the cabinet body of the electrical cabinet is divided into multiple heat dissipation channels by criss-cross isolation grooves. The radiator and reactance The resistors are distributed in the corresponding heat dissipation channels, and the gaps between the heat dissipation channels are used to accommodate the connecting part of the reactor and the heat sink. The isolation groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com