Lamp base jig

A technology of lamp pins and fixtures, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of inconvenient operation, low efficiency, and inability to realize automation, so as to achieve the effect of improving production efficiency and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

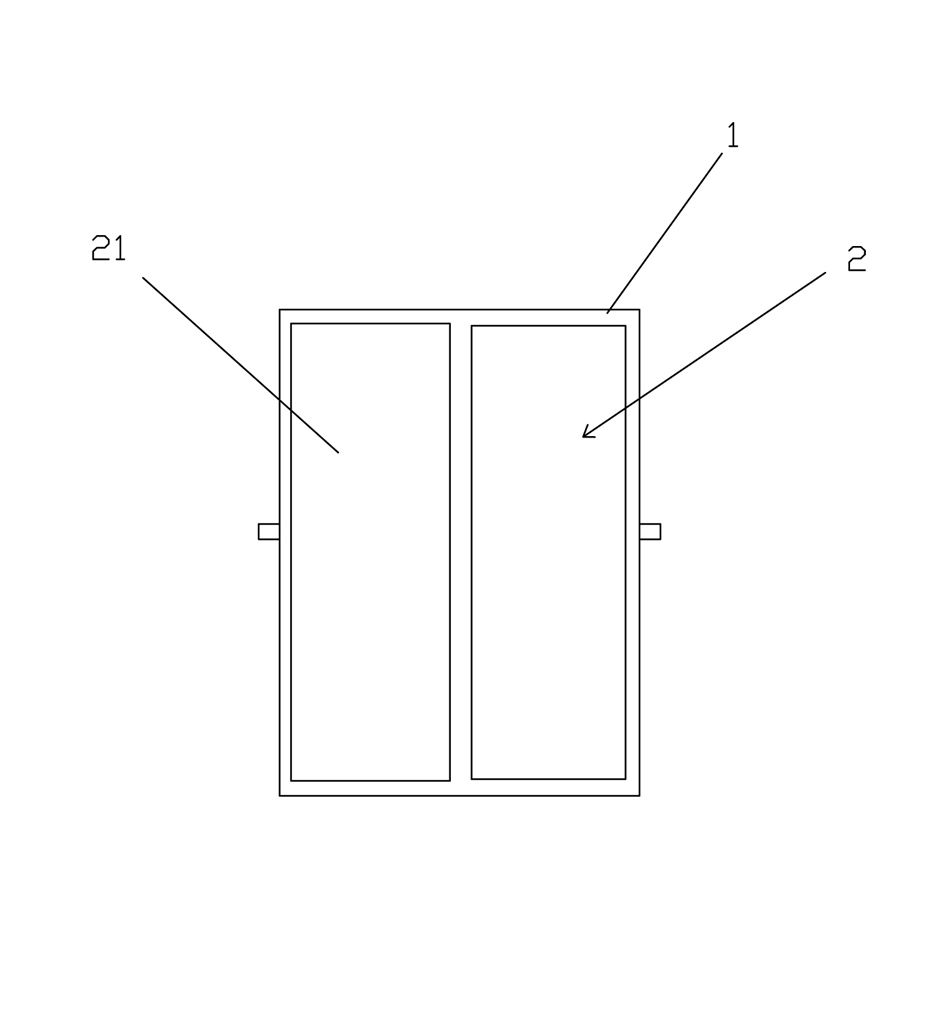

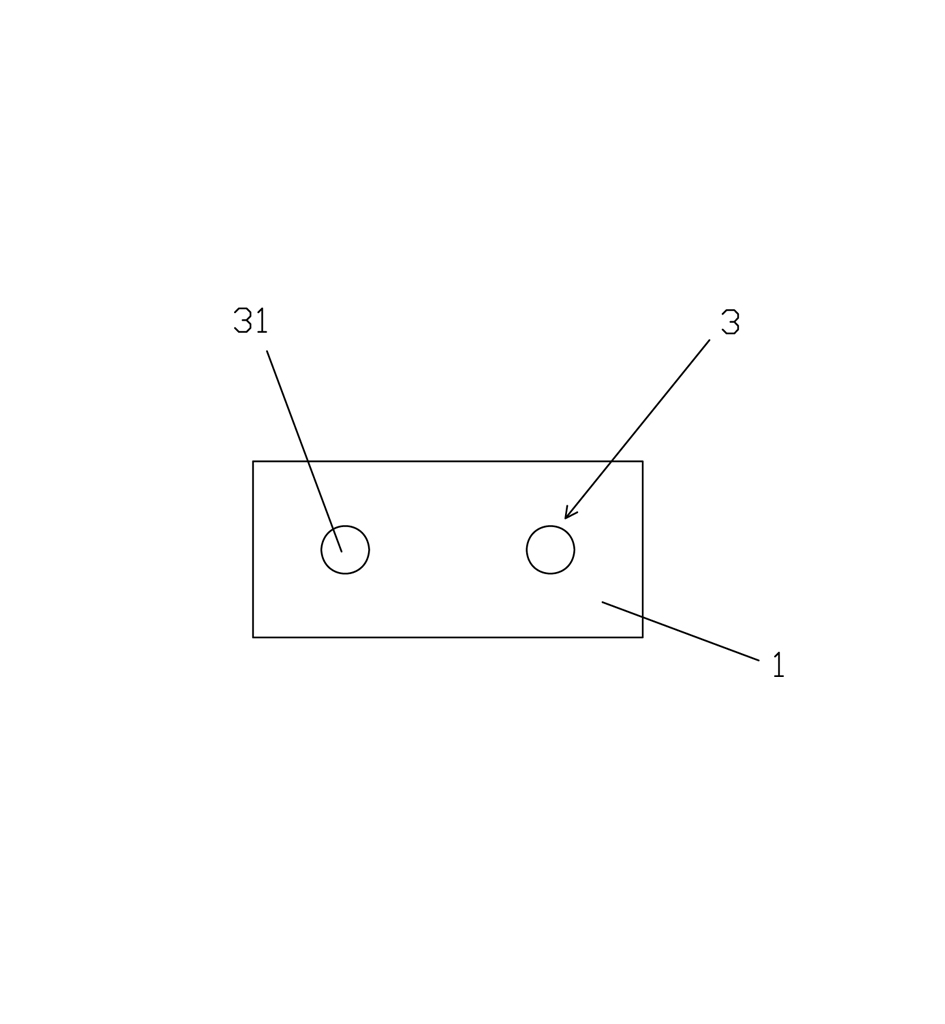

[0019] refer to figure 1 , 2 with image 3 One of the embodiments of the lamp pin fixture of the present invention includes a housing 1, a clamping mechanism 2 provided on the housing 1, an opening 3 on the side of the housing 1 for passing through the lamp pin, and the position of the clamping mechanism 2 is the same as The positions of the openings 3 are corresponding.

[0020] The clamping mechanism 2 includes a clamping block 21 hinged on the housing 1 , and an elastic element 22 arranged between the clamping block 21 and the housing 1 .

[0021] The elastic element 22 is a spring, and the spring is arranged on the end of the housing 1 opposite to the opening 3 . In addition, the elastic element 22 can also be a torsion spring, and the torsion spring is sleeved on the hinge shaft used to hinge the clamp block and the housing, and its two ends are respectively arranged on the inner bottom surface of the housing 1 and the bottom of the clamp block 21 . .

[0022] The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com