Ratchet wrench

A ratchet wrench and body technology, applied in the field of wrench tools, can solve the problems of easy-to-accumulate dust debris positioning effect, many gaps in positioning parts, complex positioning design, etc., achieve high-sensitivity action, real-time response, and avoid the effect of slow operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

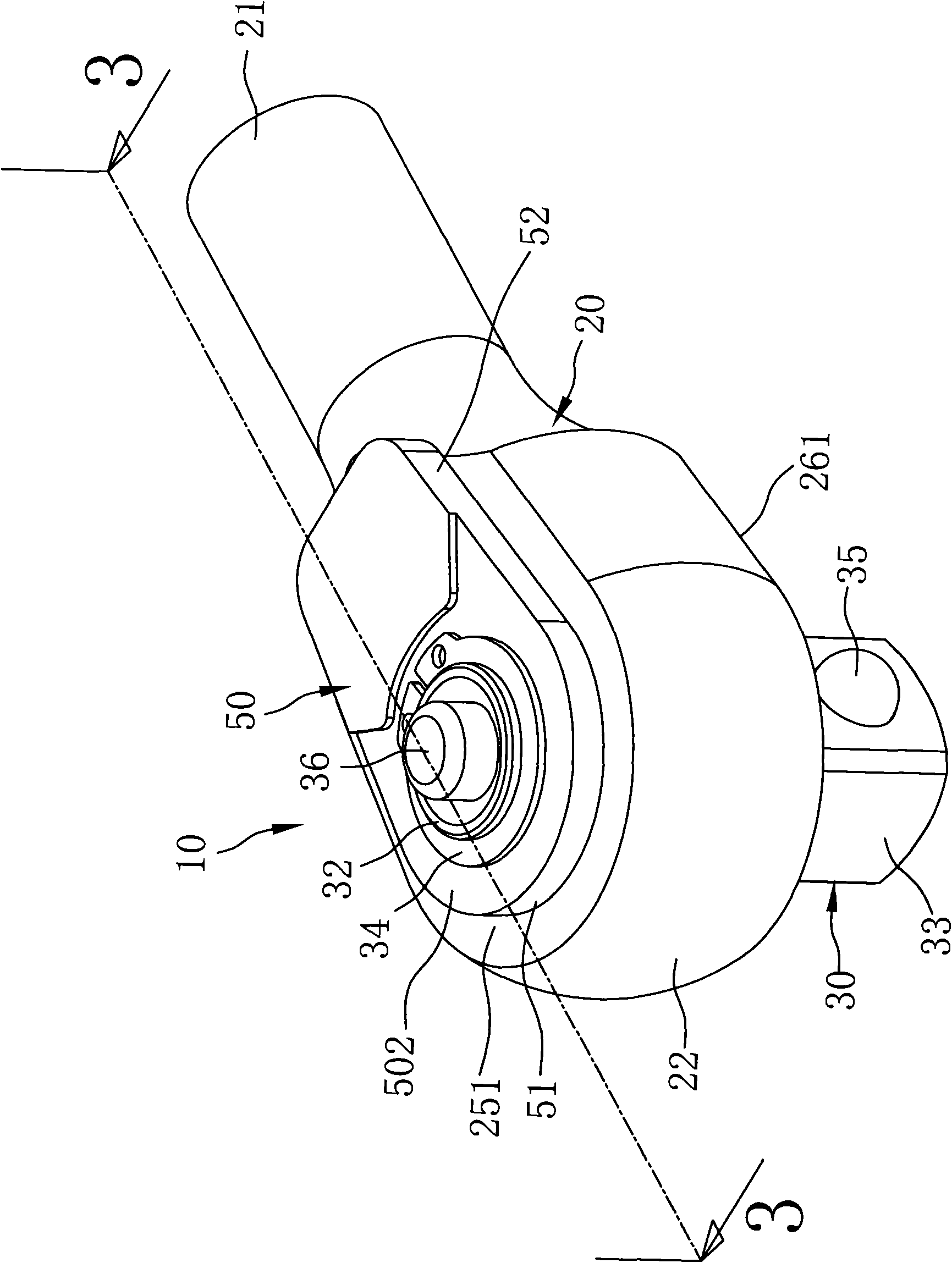

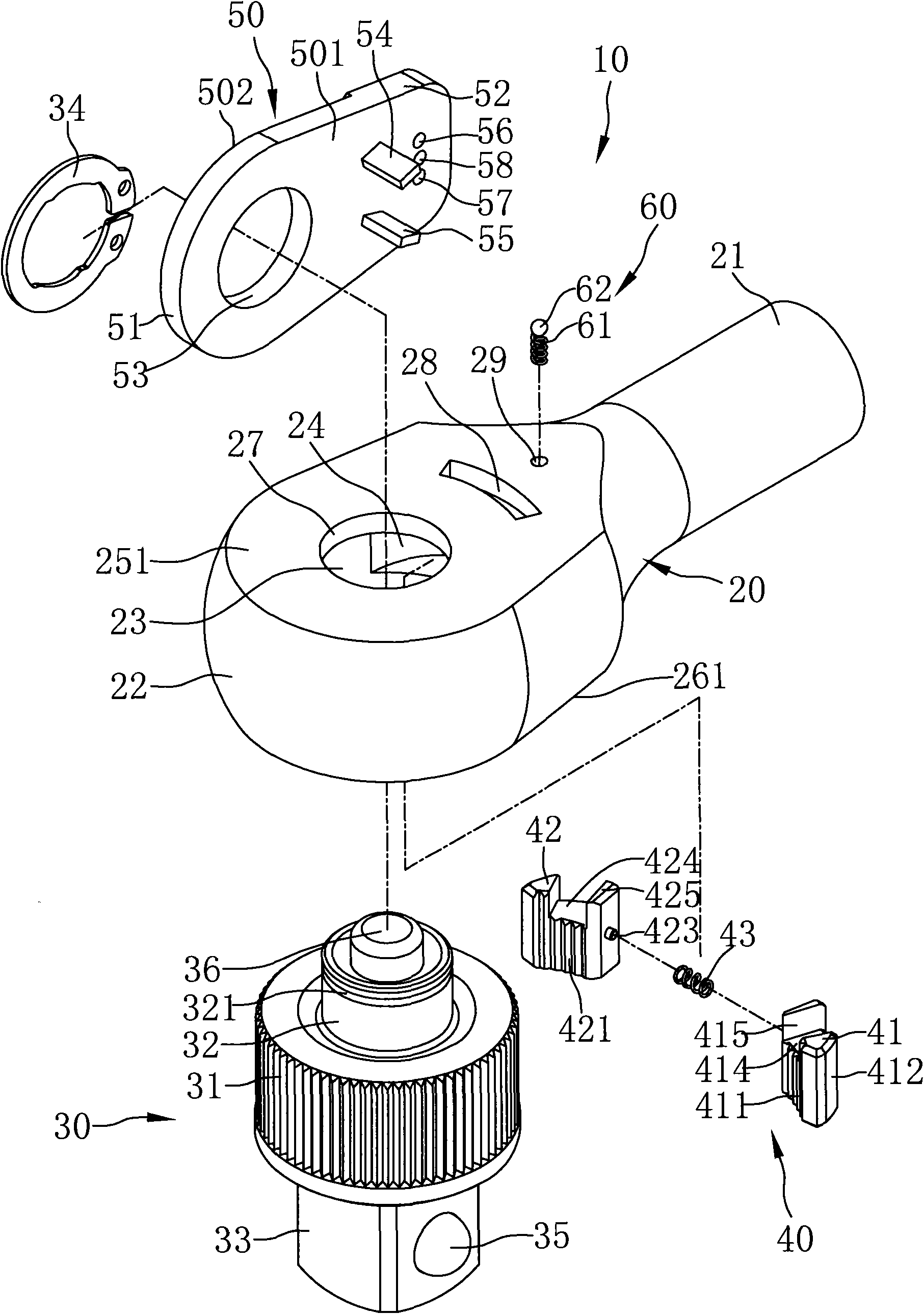

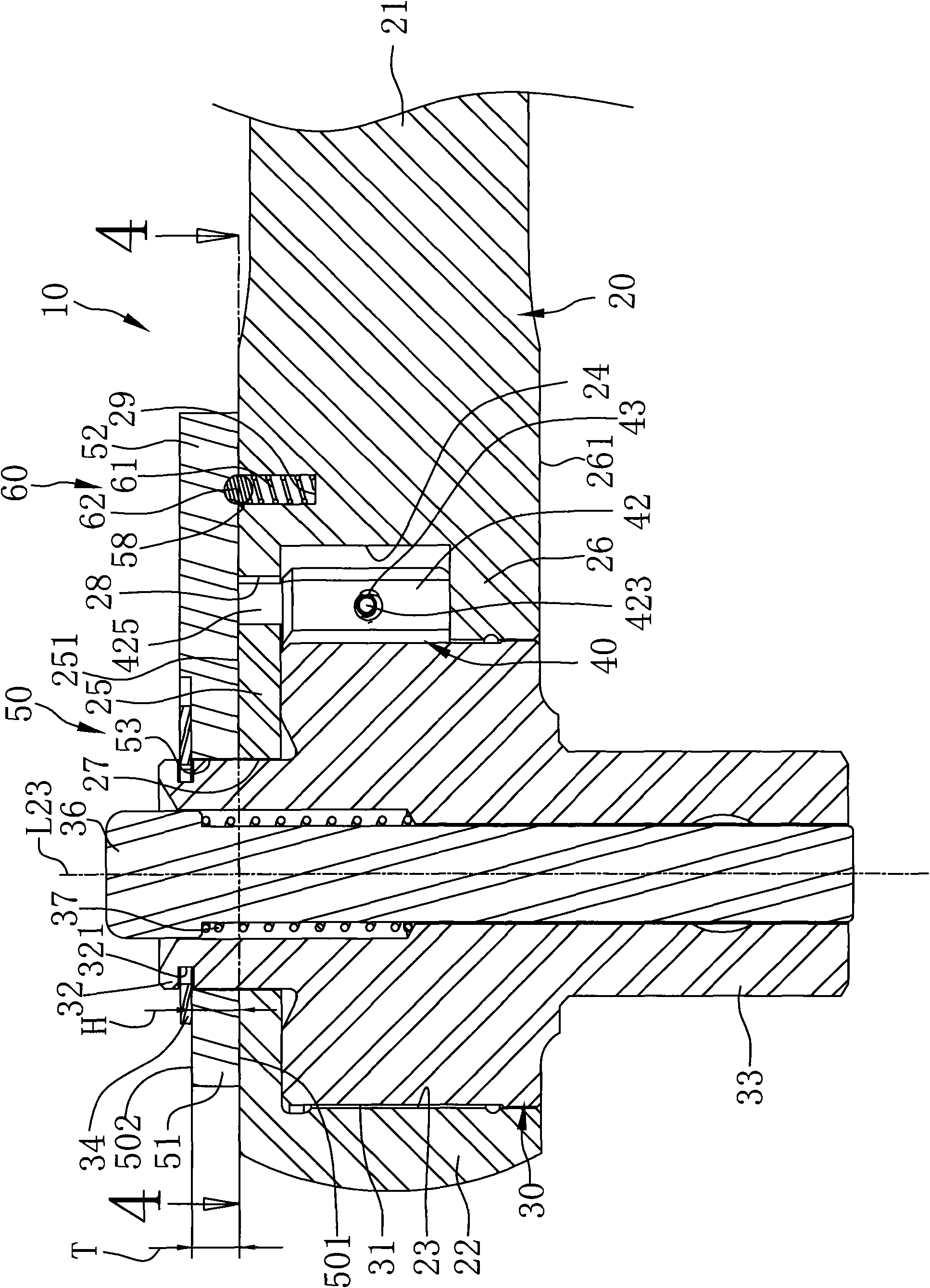

[0046] refer to Figure 1 to Figure 3 , the ratchet wrench 10 of the present invention includes a body 20, a driving body 30, a ratcheting device 40, a control member 50 and a positioning device 60; wherein:

[0047] The body 20 has a handle 21 and a head 22 arranged at one end of the handle 21. A circular first accommodation groove 23 is provided in the head 22. The first accommodation groove 23 has an axis L23, and the user The main body 20 can be rotated around the axis L23 of the first accommodating groove 23 by operating the handle 21 . The head 22 is provided with a first stop wall 25 and a second stop wall 26 opposite to each other, and the head 22 is formed with a first plane 251 on the outer surface of the first stop wall 25, and the head 22 is formed on the second stop wall 26. A second plane 261 is formed on the outer surface of the body. The first plane 251 and the second plane 261 are parallel to each other and spaced apart from each other and perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com