Pneumatic device for assembling back surface sleeve of automobile and assembly method thereof

A technology of pneumatic device and face cover, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of high cost of negative pressure system, low production efficiency, troublesome maintenance, etc., so as to reduce production cost, high production efficiency and labor intensity. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

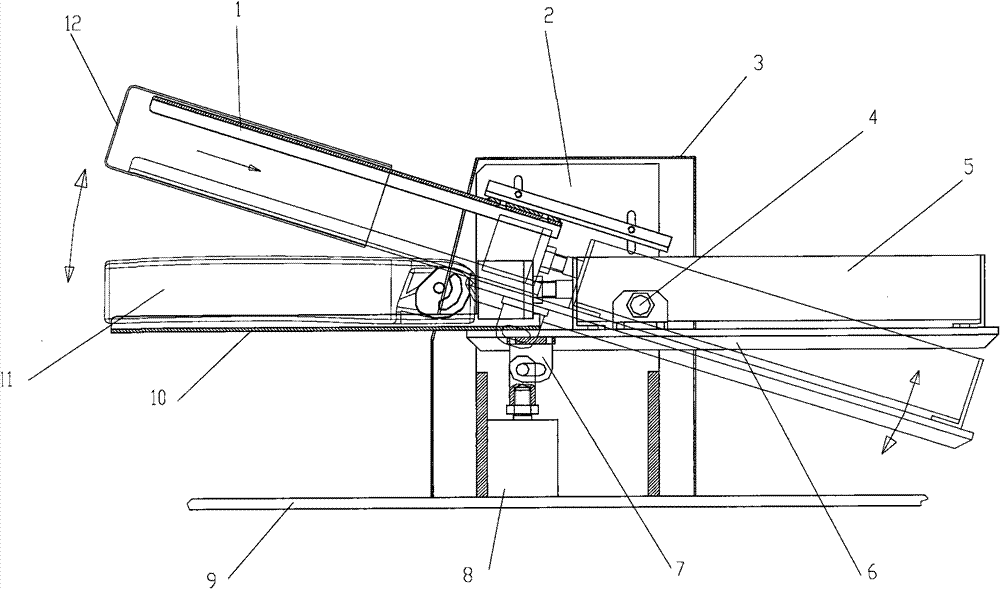

[0030] figure 1 The structure shown is the pneumatic device for assembling the back cover of the automobile according to the present invention, including the overturn bracket 2 positioned on the work surface 9, the upper groove tongue plate 1 and the overturn plate 6 fixed on the overturn bracket 2, and the overturn plate 6 One end is provided with the lower groove tongue plate 10 opposite to the upper groove tongue plate 1 position, and the other end is equipped with a push cylinder 5, and the push block on the push cylinder 5 can be formed by the upper groove tongue plate 1 and the lower groove tongue plate 10. Move in the chute; the overturning plate 6 is fixed on the overturning support 2 by the overturning shaft 4, and the overturning plate 6 can rotate on the overturning support 2 around the overturning shaft 4, and the outside of the overturning support 2 is covered with a cover 3.

[0031] The overturning plate 6 pushes the overturning plate 6 to rotate through the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com