Stem wave elimination device

A wave-absorbing device and bow technology, applied in the direction of hull, ship propulsion, ship parts, etc., can solve problems such as difficult to change, and achieve the effect of reducing wave resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

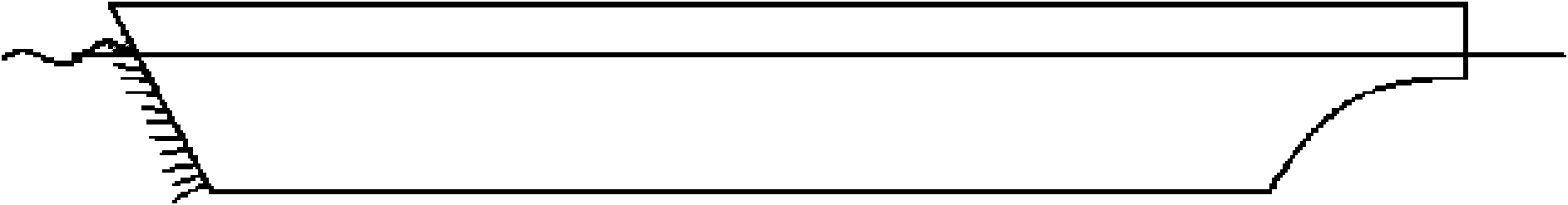

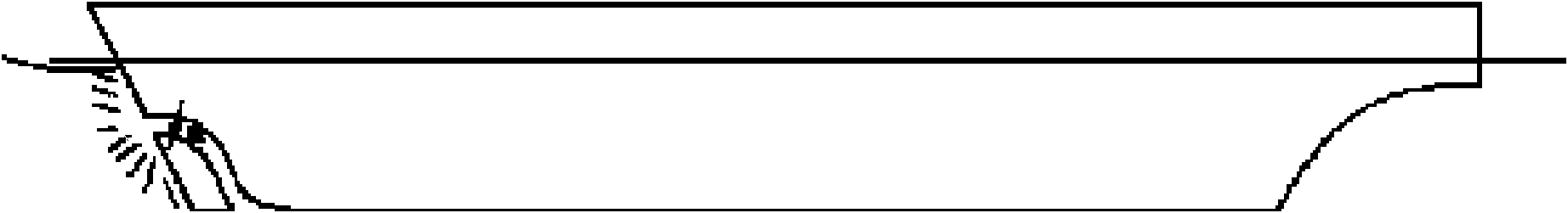

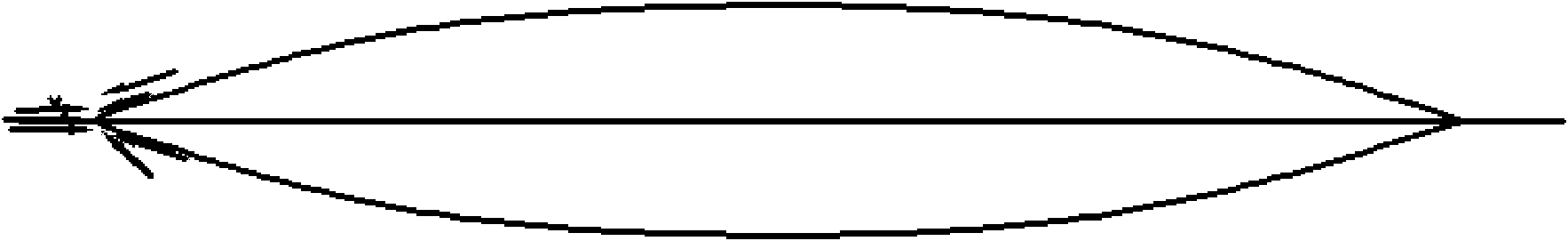

[0026] combine Figure 8 , the bow wave damping device is located at the bow of the ship, a pipeline 3 is arranged inside the bow, the angle of the entrance is horizontal, and the inside is turned to the bottom of the ship through a rounded corner; same. When the propeller is moving forward, due to the suction effect generated by the rotation of the propeller in the duct, the incoming flow in front of the ship no longer bulges and forms waves due to the propulsion of the ship, but moves quickly downward and backward along the wave dissipation device. Thus avoiding the generation of waves; due to the suction effect of the wave absorbing device, the direction of the water flow near the bow changes, and the direction of the water flow relative to the ship is the same as that of the ship itself, so the direction of friction between the hull and the water It is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com