Electromagnetic wave heater for asphalt heating

An electromagnetic wave and heater technology, applied in the field of electromagnetic wave heaters, can solve problems such as safety production accidents, low thermal efficiency, coking, etc., and achieve the effects of ensuring safe production, high heat conversion efficiency, and strong penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

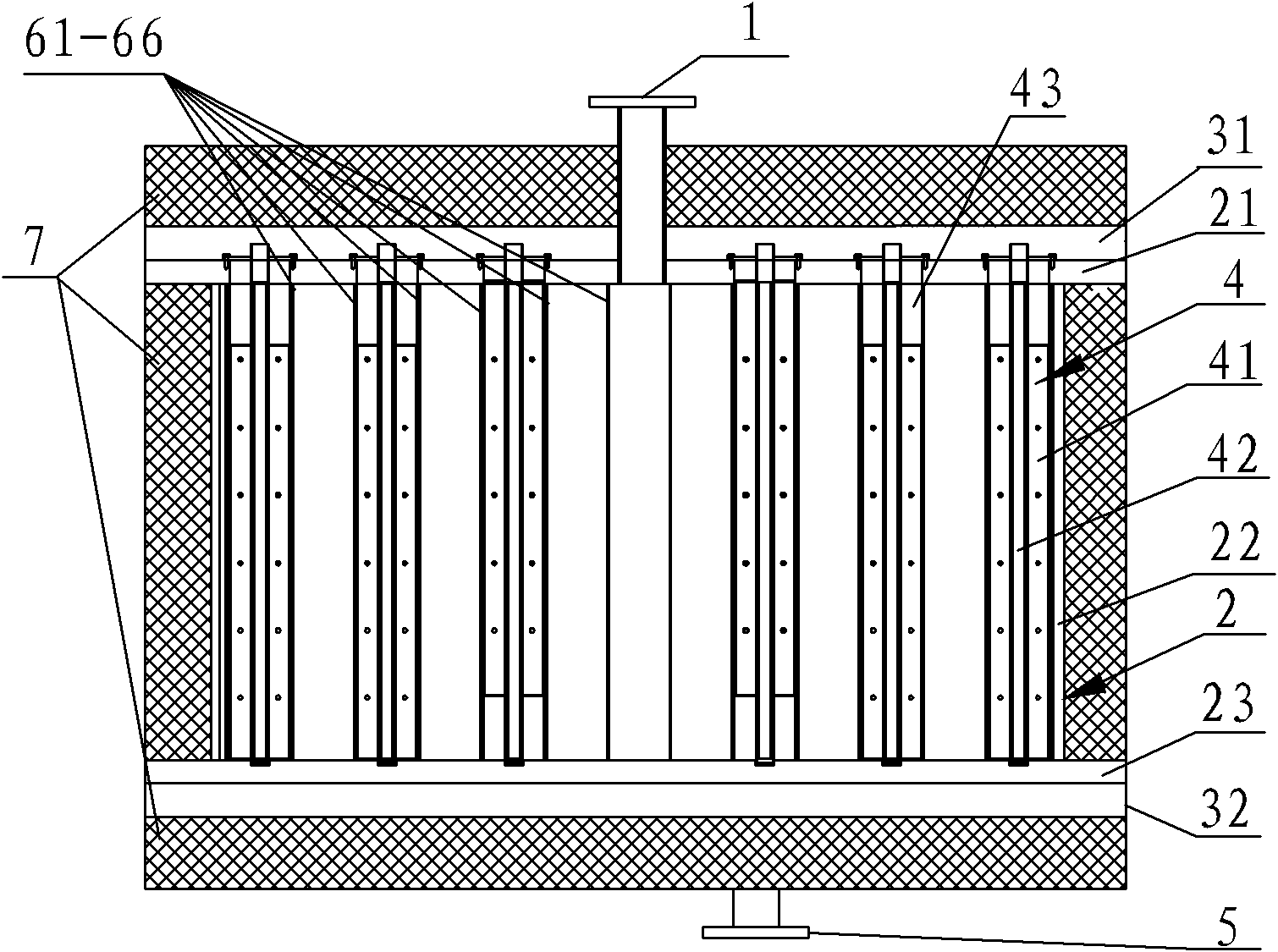

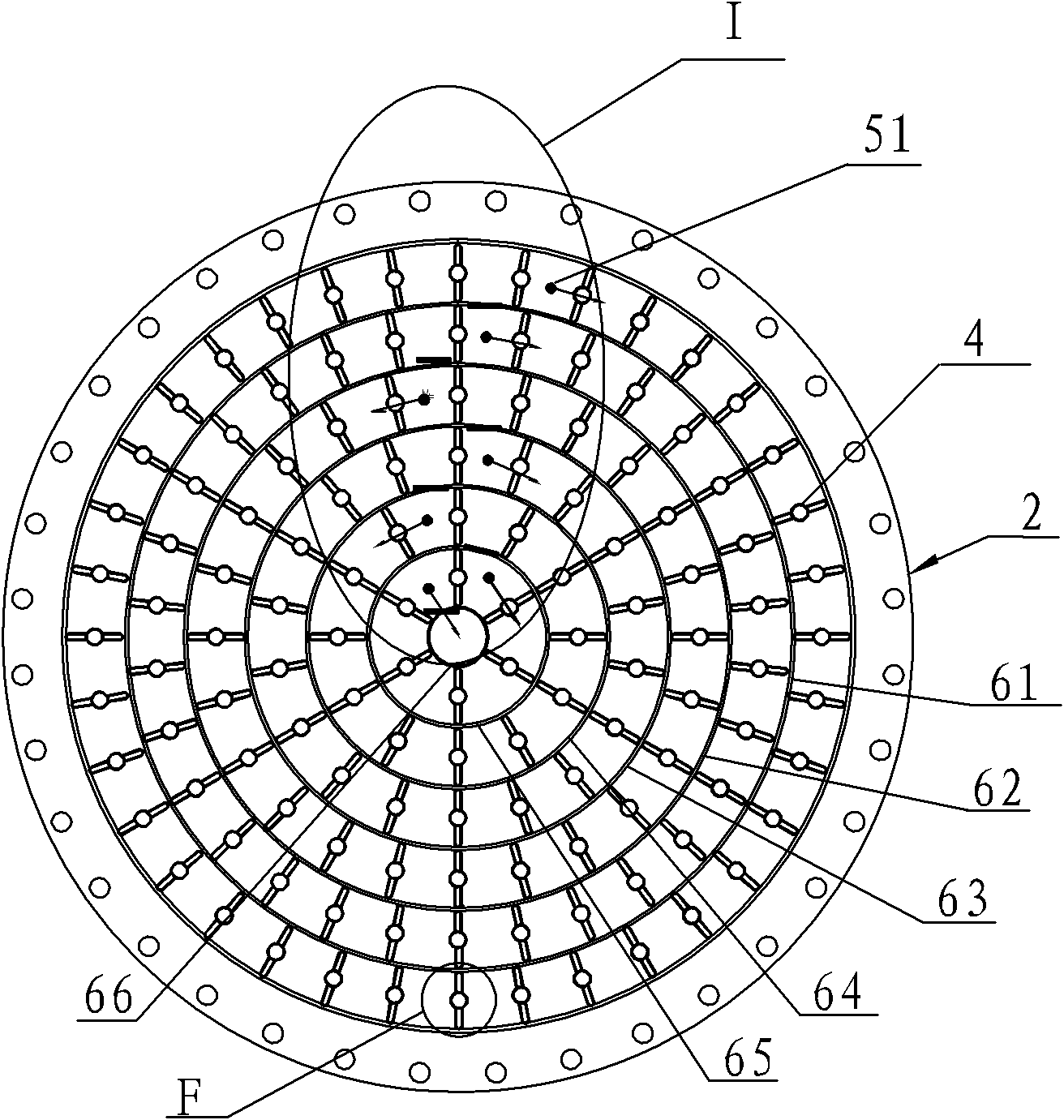

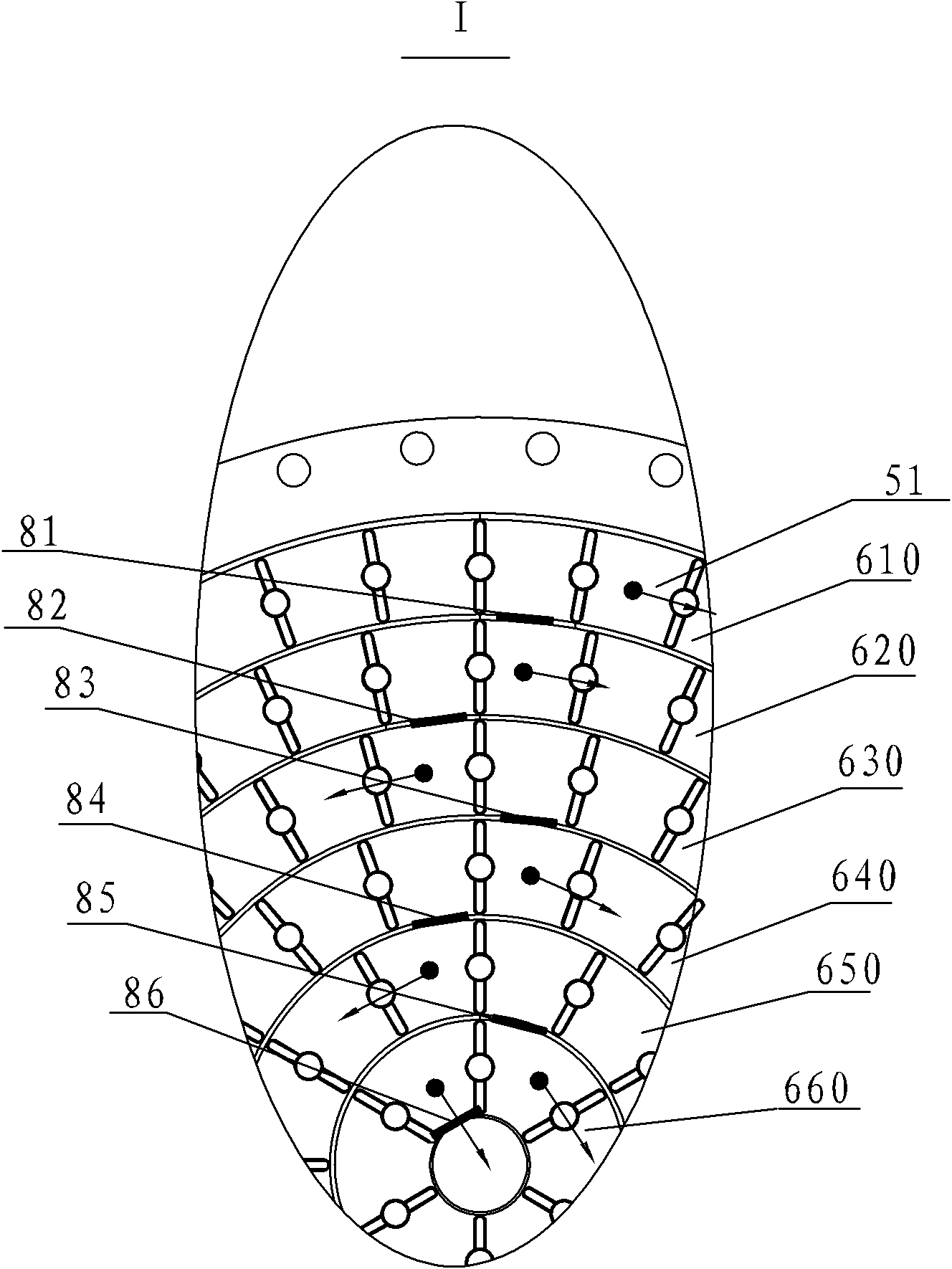

[0016] Figure 1 ~ Figure 4 It shows an electromagnetic wave heater for asphalt heating, which is characterized in that a cylindrical shell 2 is provided, and more than 5 layers are arranged coaxially with the cylinder 22 to form a ring shape between the upper and lower covers 21 and 23 of the shell. For the cylindrical partition of the flow channel, 6 layers of cylindrical partitions 61-66 are set in this embodiment to form annular flow channels 610-660; several strip-shaped vertical partition type electromagnetic wave heating bodies 4 run through the shell, The lower covers 21 and 23 are uniformly arranged in the radial direction between adjacent cylindrical partitions, and divide the annular flow channel into several fan-shaped cross-section heat exchange areas; the upper or lower end of the above-mentioned electromagnetic wave heating body 4 is provided with an overflow port 43, and the flow opening of the adjacent electromagnetic wave heating body is set at the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com