Crumb rubber modified asphalt electromagnetic wave heating device and safety system

A modified asphalt and heating device technology, which is applied in the direction of melting and processing tar asphalt/petroleum asphalt/natural asphalt, building components, building insulation materials, etc., can solve problems such as safety production accidents, low thermal efficiency, and scrapped heaters, and achieve accurate Control the heating temperature, high heat conversion efficiency, and ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

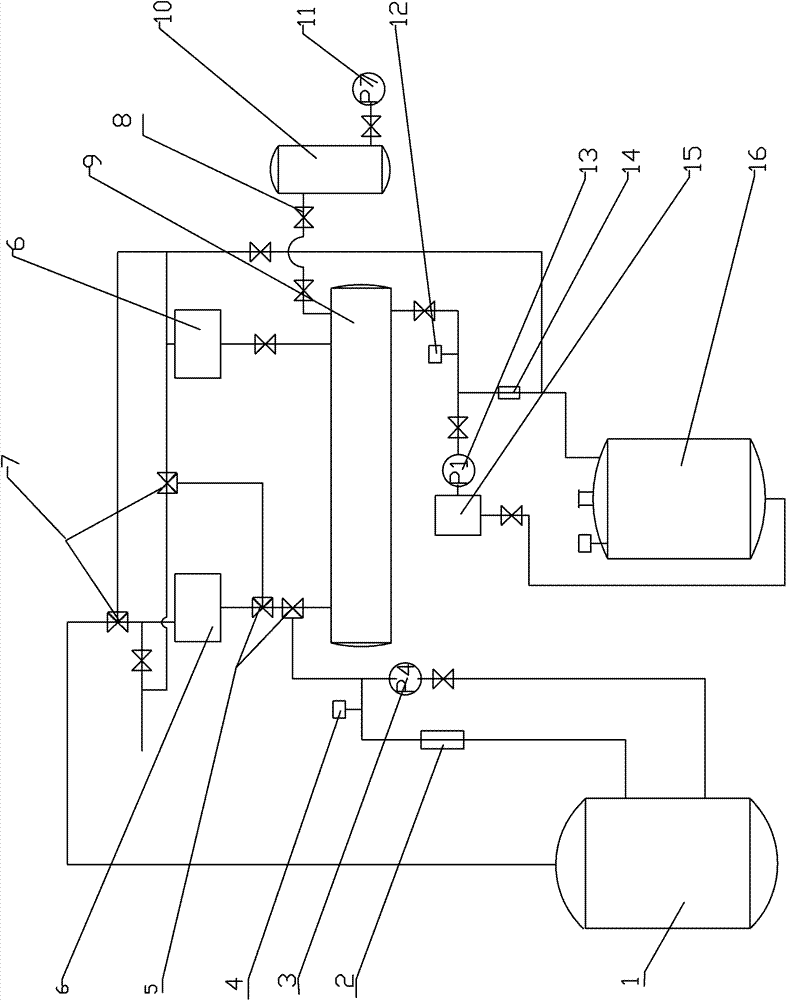

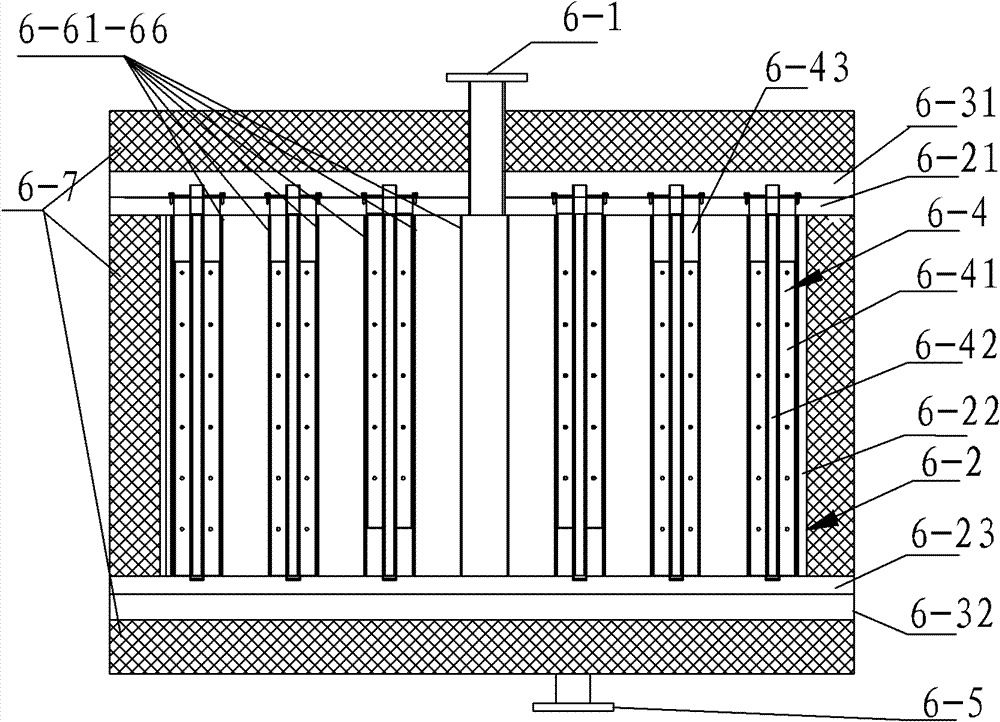

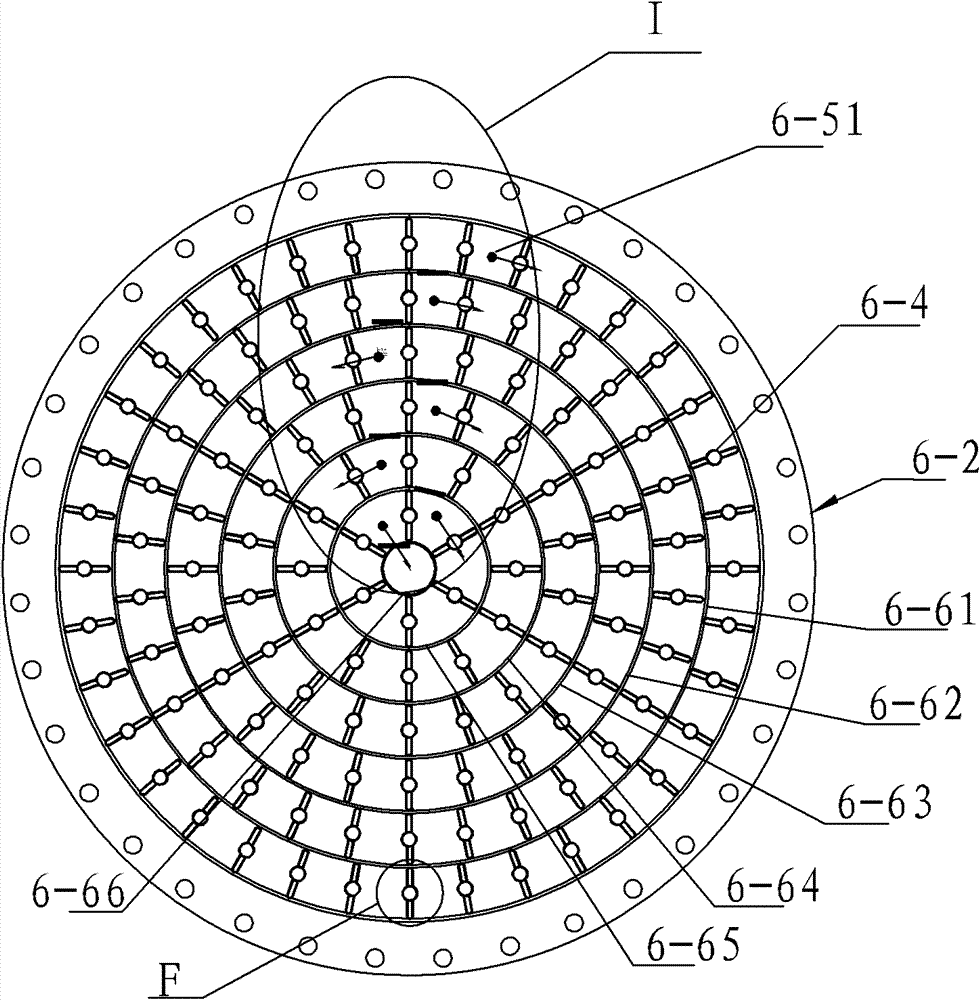

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a rubber powder modified asphalt electromagnetic wave heating device and a safety system include a rubber powder modified asphalt finished product tank 1, a base asphalt raw material tank 16 and valves between connecting pipelines. The safety system is mainly composed of air A compressor 11, a compressed air storage tank 10, a waste heat replacement safety tank 9, and a special thermal insulation safety valve for asphalt are composed of three-way thermal insulation ball valves. The storage tank is connected with the waste heat replacement safety tank through the valve 8, the outlet of the waste heat replacement safety tank is connected with the electromagnetic wave heater 6 and the rubber powder modified asphalt finished product tank 1 through the asphalt special thermal insulation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com