Device and process for extracting phosphorus from phosphorus mud

A phosphorus sludge and process technology, applied in phosphorus compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of difficult equipment sealing, frequent equipment maintenance, low phosphorus extraction rate, etc. The effect of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

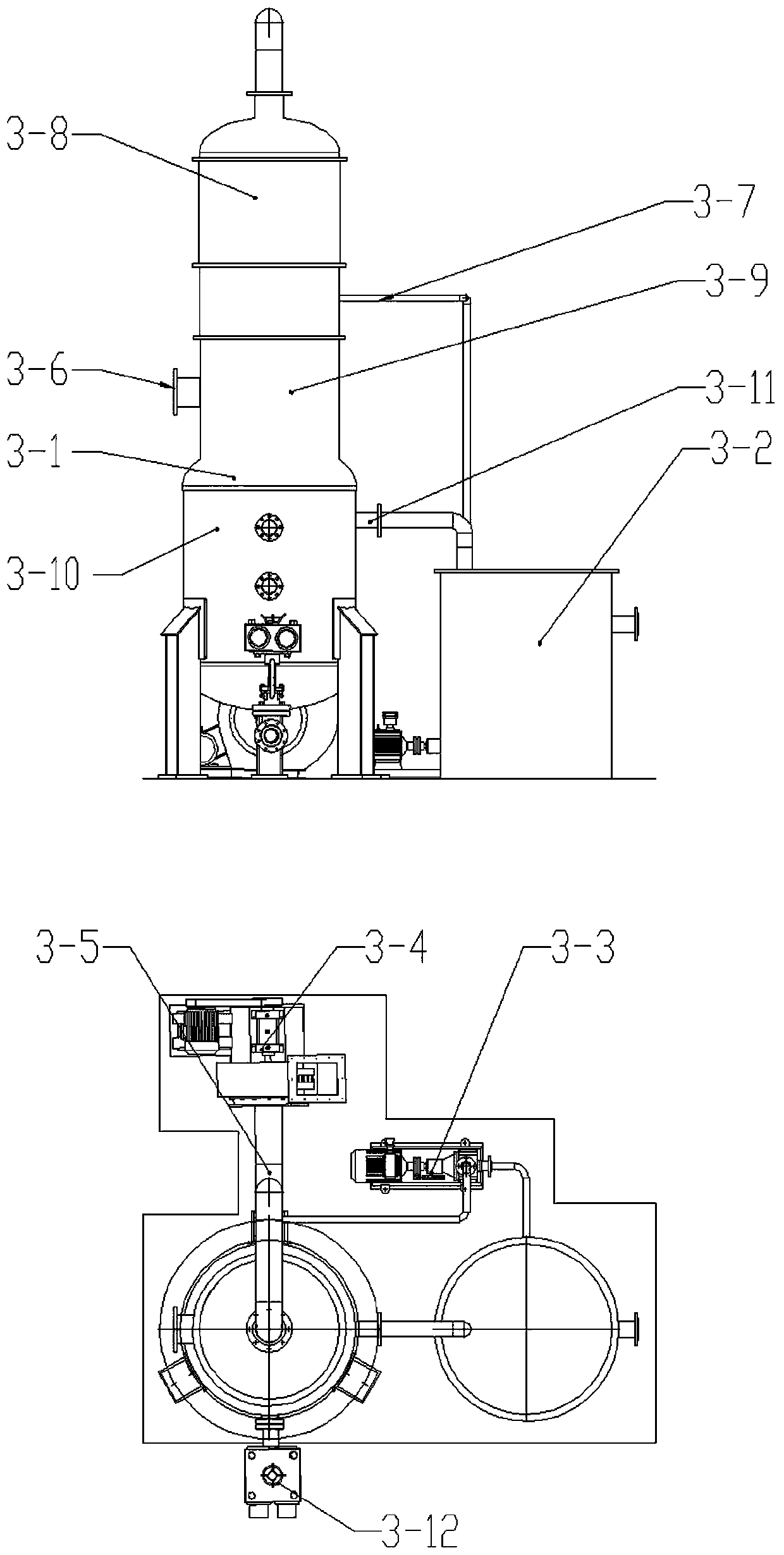

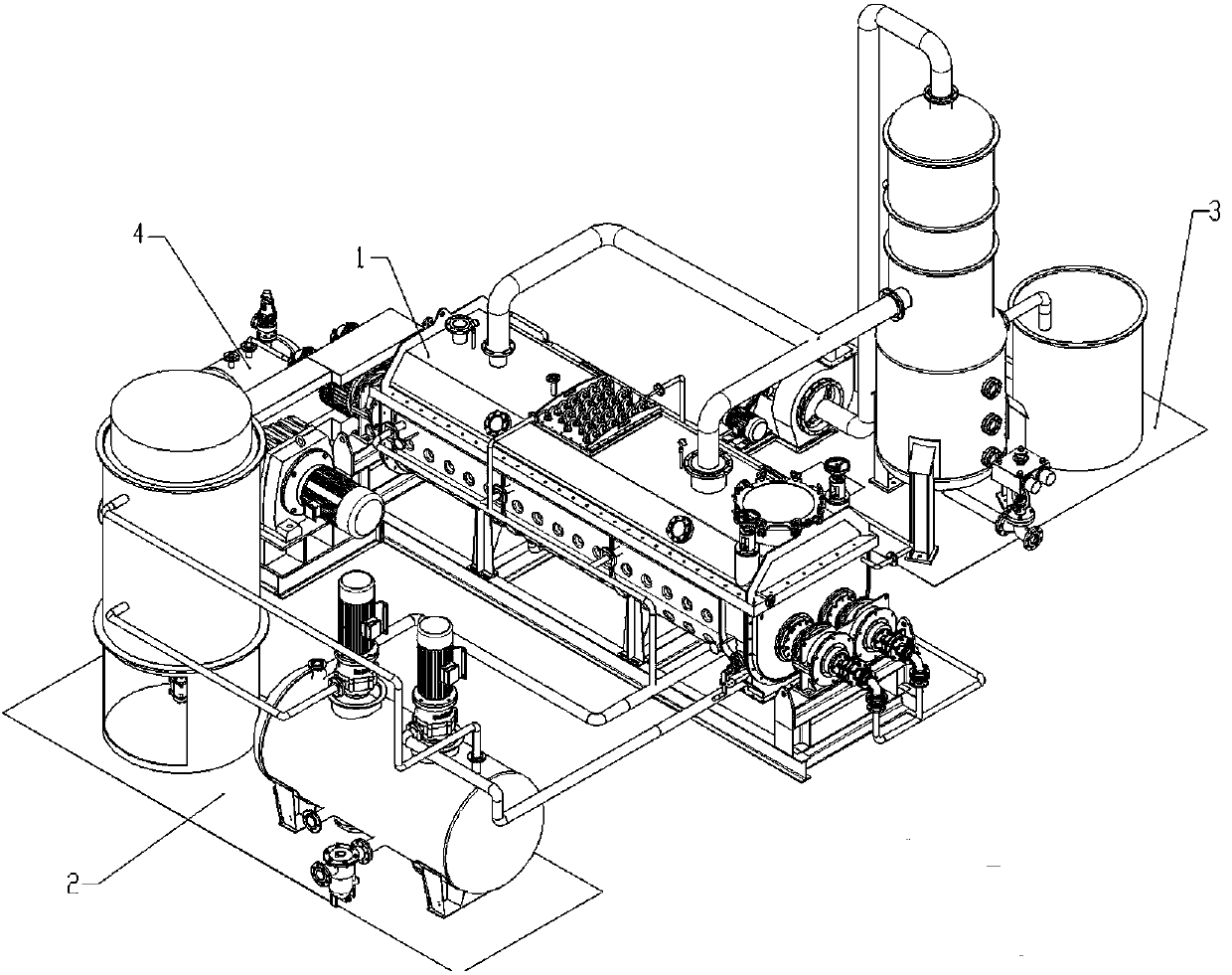

[0056] A device for extracting phosphorus from phosphorus sludge, such as figure 1 As shown, it consists of phosphorus sludge evaporator 1, heat source device 2, phosphorus recovery device 3, and emergency blowback device 4;

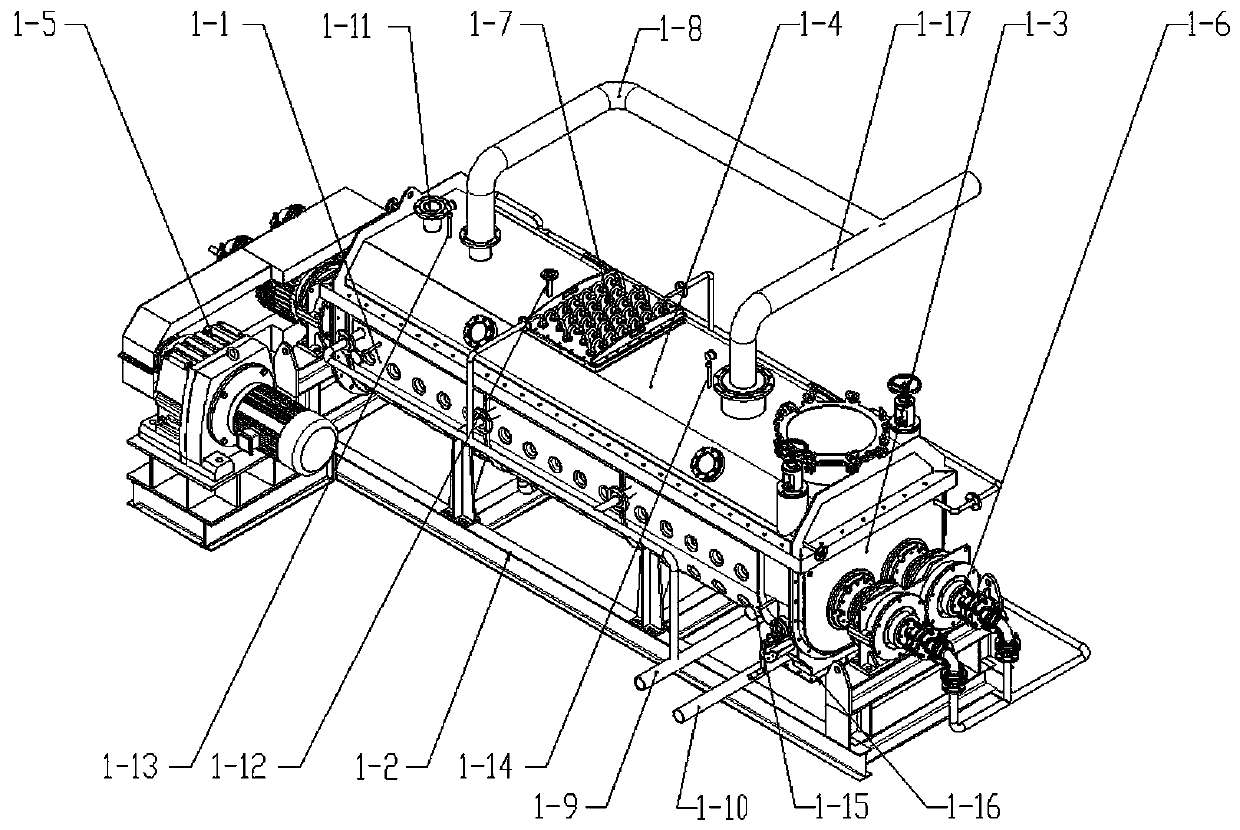

[0057] Phosphorus sludge evaporator 1, such as figure 2 As shown, it includes a cavity composed of a housing 1-1, an end cover 1-3, an upper cover 1-4, a transmission device 1-5 communicating with the cavity, an integral base 1-2, a shafting 1-6 and the arrangement The preheater 1-7 on the loam cake 1-4;

[0058] The cavity, the transmission device 1-5, and the shafting 1-6 are installed on the integral base 1-2,

[0059] The upper cover 1-4 is provided with a feed inlet 1-11, a nitrogen inlet 1-12, exhaust pipes 1-8 and 1-17, and the exhaust pipe 1-8 is connected to the exhaust pipe 1-17;

[0060] The housing 1-1 is provided with an overflow plate; the bottom of the housing is provided with a discharge port 1-16, and the overflow plate communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com