Brake pad for train

A technology for brake pads and trains, which is applied in the direction of friction linings, mechanical equipment, etc., and can solve the problems of falling blocks, cracks and defects of brake pad friction blocks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

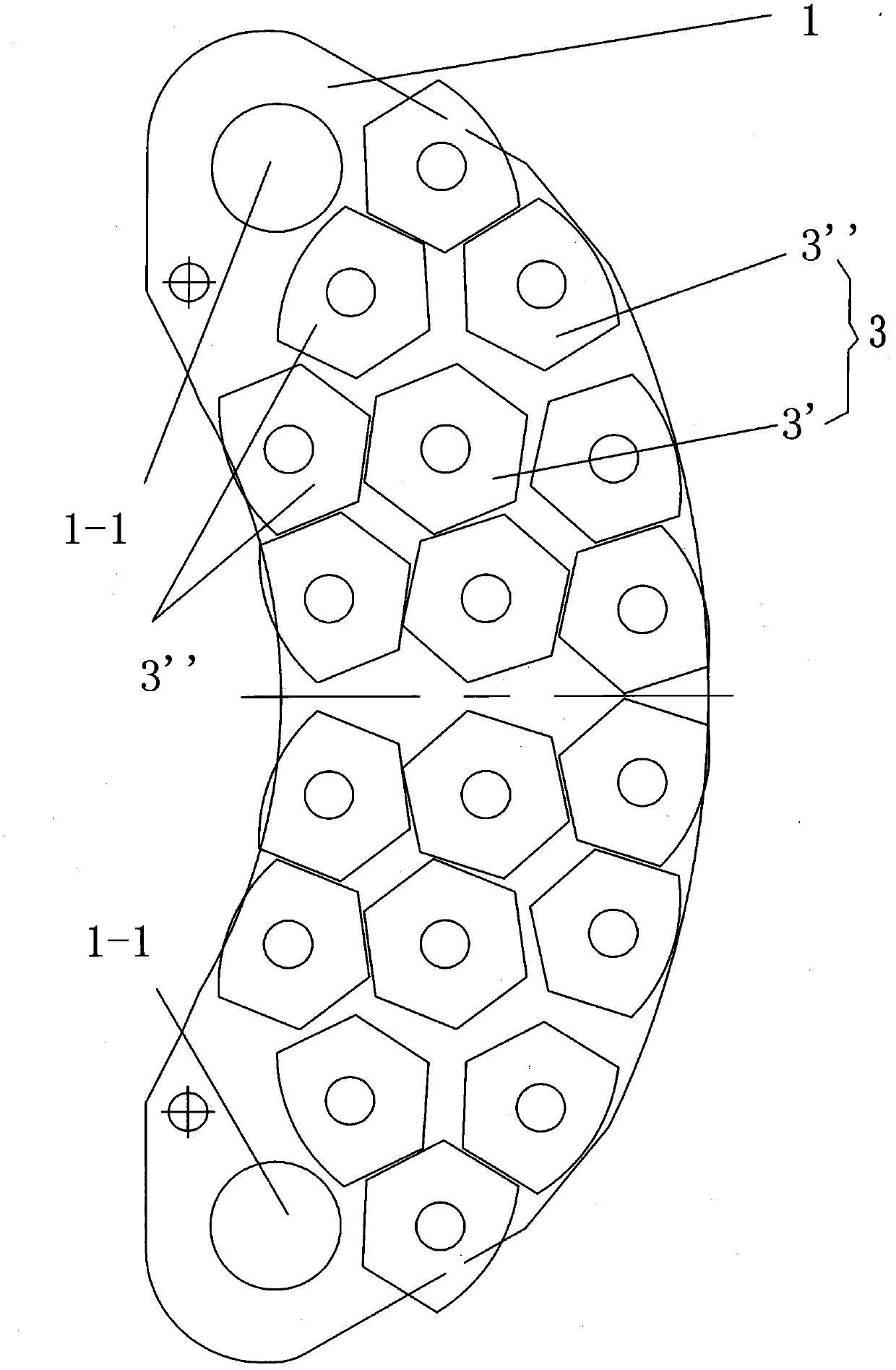

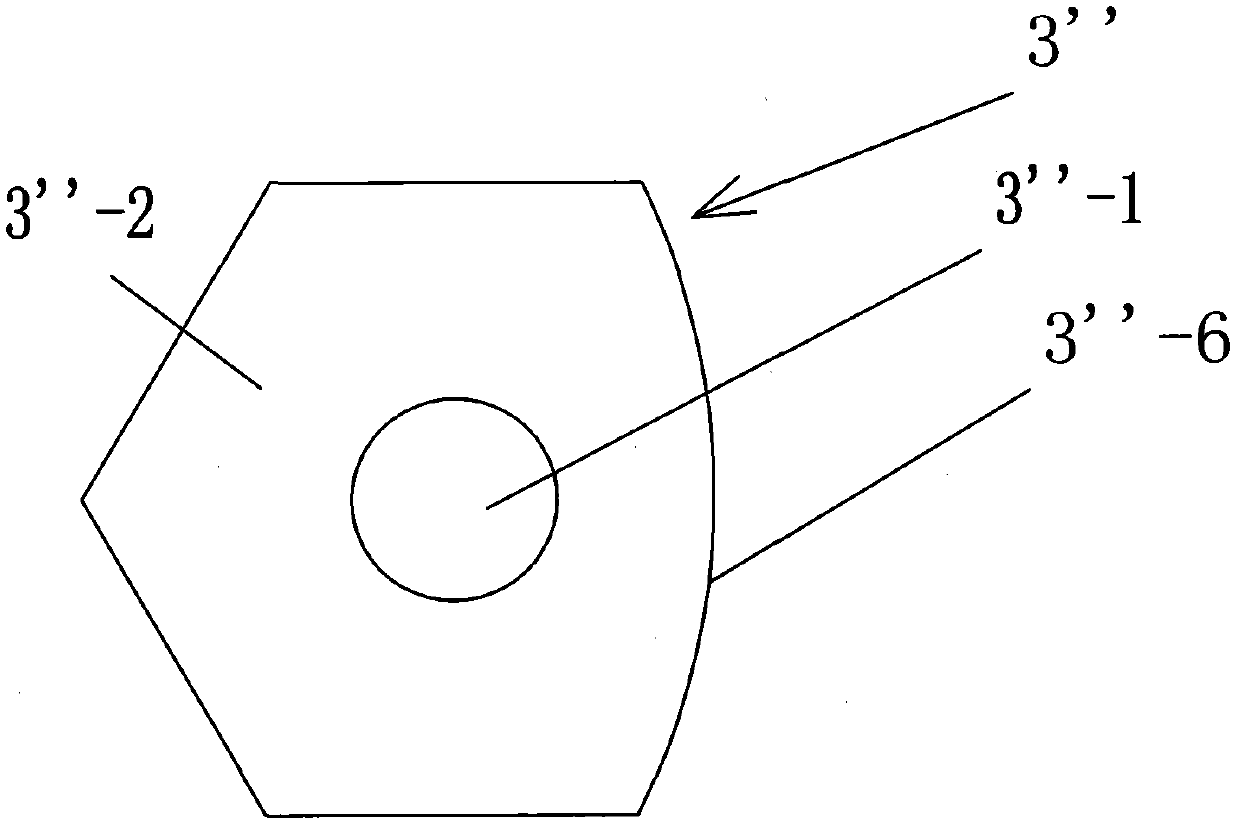

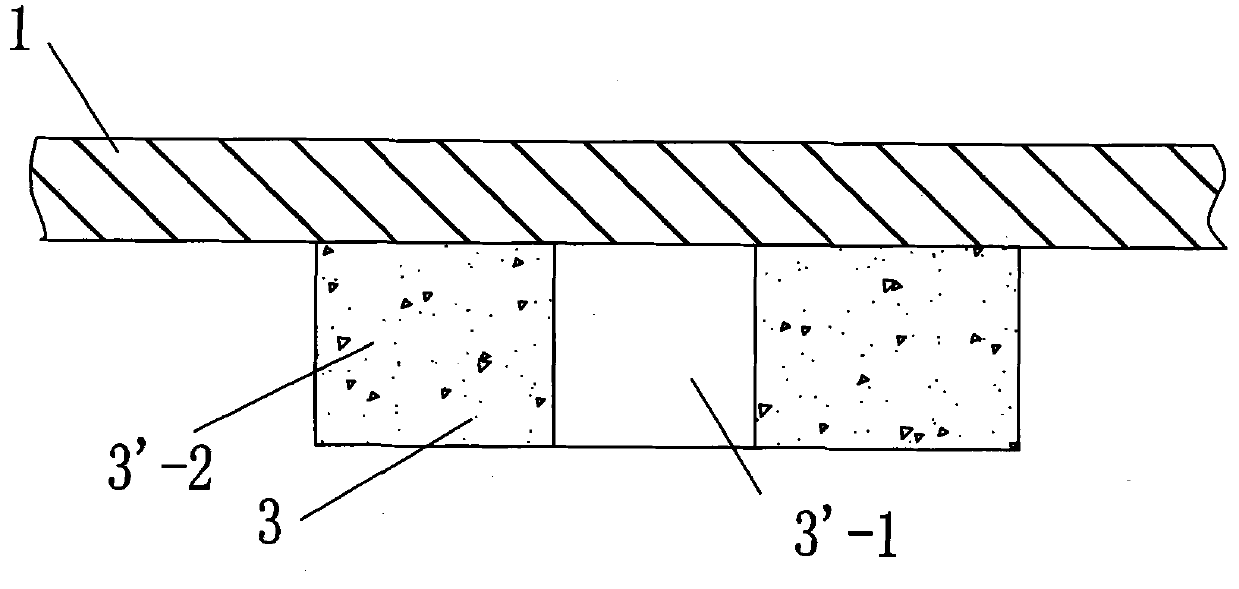

[0024] Such as figure 1 , 2 , 3, the first embodiment of the present invention, a train brake pad, including a mounting plate 1 and a friction block 3, the friction block 3 is installed on the mounting plate 1, the friction block 3 is divided into a first friction block 3' and the second friction block 3"; the first friction block 3' is a hexagonal body, and the second friction block 3" is a pentagonal body; among the five sides of the second friction block 3", the one facing the outside of the mounting plate 1 One surface is a convex arc surface 3"-6; the second friction block 3" is distributed along the front of the mounting plate 1 and surrounds the first friction block 3' in the middle.

[0025] Such as figure 2 , 3 As shown, the upper part of the first friction block 3' is a powder layer 3'-2 and the powder layer 3'-2 has a middle hole 3'-1, and the upper part of the second friction block 3" is a powder layer 3"-2 And the powder layer 3"-2 has mesopores 3"-1.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com