Heat transfer tube for improving tube bundle effect

A heat transfer tube and groove height technology, which is applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of improved heat exchange performance and high heat exchange performance on the condensation side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

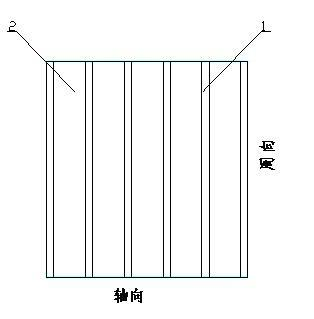

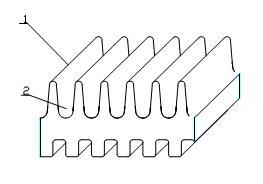

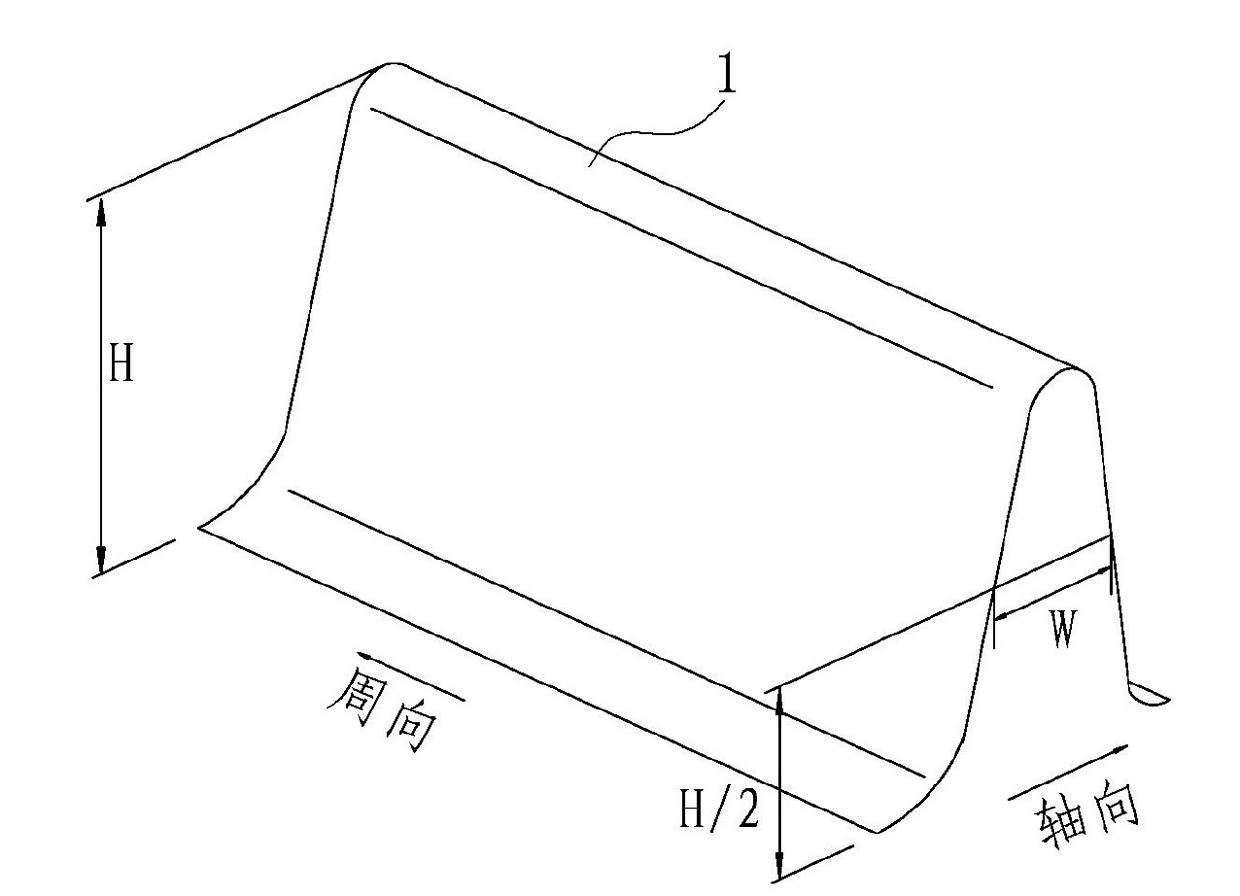

[0043] see image 3 , the heat transfer tube provided in this embodiment is based on the existing heat transfer tube, by using a thinner slotting tool to process fin grooves 304 on the top of part of the fins 301, and the fins 301 are formed along the circumferential direction There are inter-fin slots 302, and fin platforms 303 are formed between adjacent inclined slots.

[0044] In this embodiment, when the fin grooves are processed, a fin groove is formed every two smooth fins on the fins of the heat transfer tube.

[0045] Based on the above scheme, if it is assumed that the code name of the smooth fin without fin groove is "0", and the code name of the slotted fin with fin groove is "1", such as image 3 As shown, in this embodiment, the number of fin heads is 3, and there is a fin slot for every two smooth fins along the axial direction on the fin, and the "001001" type heat transfer tube can be processed. Obviously The ratio of smooth fins is 2 / 3.

[0046] In the pre...

Embodiment 2

[0059] In the heat transfer tube provided in this embodiment, when the fin grooves are processed, two fin grooves are continuously formed on every two smooth fins on the fins of the heat transfer tube.

[0060] see Figure 4 , in the present embodiment, the number of fin heads is 4, and the fin grooves 304 are opened every two fins on the fin 301 in the axial direction, and the heat transfer tube of the "0011" type can be processed (K=1 / 2 ). And other structures are the same as the heat transfer tube provided in Embodiment 1, as mentioned above, and will not be repeated here.

Embodiment 3

[0062] In the heat transfer tube provided in this embodiment, when the fin grooves are processed, two fin grooves are continuously formed on every other smooth fin on the fins of the heat transfer tube.

[0063] see Figure 5 , in this embodiment, the number of fin heads is 3, and each fin opening groove 304 is spaced apart on the fin 301 in the axial direction, and the heat transfer tube of the "011011" type can be processed (K=1 / 3) . And other structures are the same as the heat transfer tube provided in Embodiment 1, as mentioned above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com