Method for preparing pyramidal patterned substrate through twice corrosion

A patterned substrate, cone-shaped technology, applied in the field of optoelectronics, can solve the problems of difficult control, difficult control, fast sulfuric acid corrosion rate, etc., and achieve the effect of increasing the light emitting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

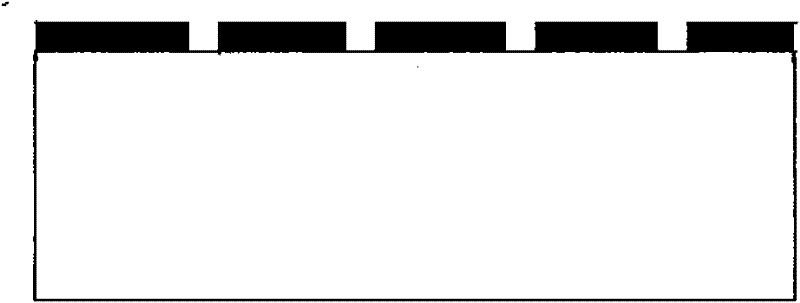

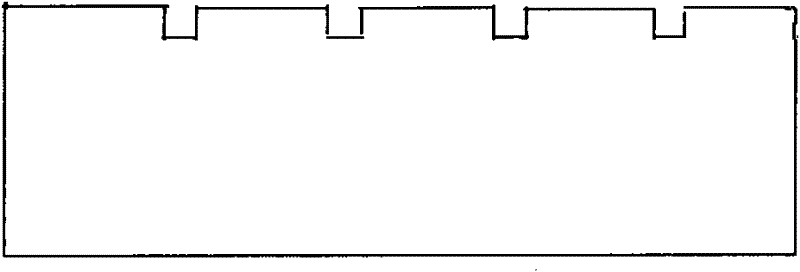

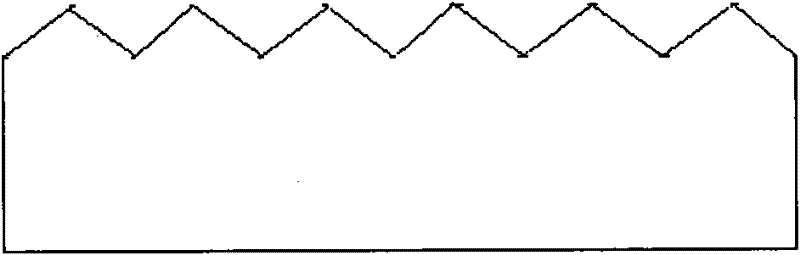

[0015] Such as figure 1 As shown, a circular silicon dioxide or silicon nitride pattern is etched on the sapphire substrate, and then the first etching is carried out in a mixed solution of sulfuric acid and phosphoric acid at 230°C-300°C, and the silicon dioxide or nitrogen is removed by conventional methods Silicon mask, that is, to get the first etched sapphire pattern, such as figure 2 shown. The temperature of the mixed solution of sulfuric acid and phosphoric acid is kept stable at 230°C-300°C, and the sapphire pattern etched for the first time is etched in the mixed solution for the second time, that is, without silicon dioxide or silicon nitride mask etching, and the second Secondarily etched tapered sapphire patterned substrates, such as figure 2 shown.

[0016] The double-etching preparation method of the tapered pattern substrate of the present invention specifically comprises the following steps:

[0017] (1) Use PECVD to deposit a 0.1-1um silicon dioxide lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com